Method for saving energy and attenuating vibration of automated mechanical system having motion-stoppage movement pattern

A motion mode and mechanical system technology, applied to mechanical equipment, transmission devices, belts/chains/gears, etc., can solve problems such as aggravated impact and increased inertia, and achieve the effects of improving energy saving, reducing drive energy consumption, and reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

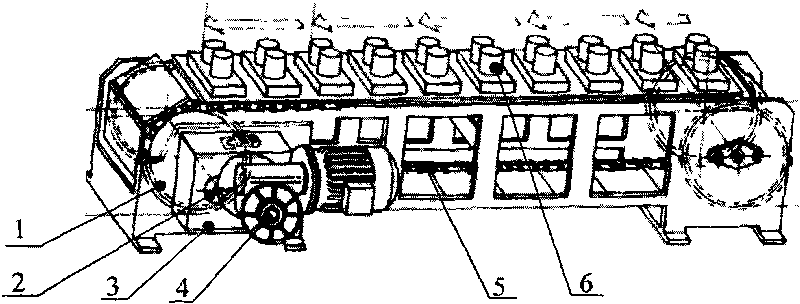

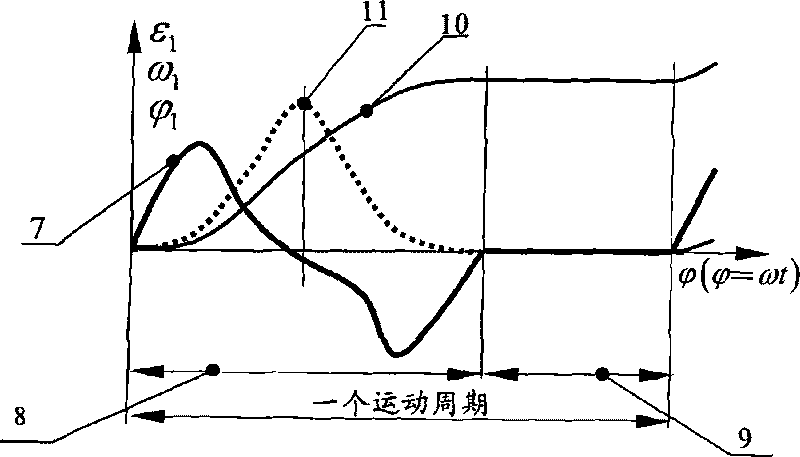

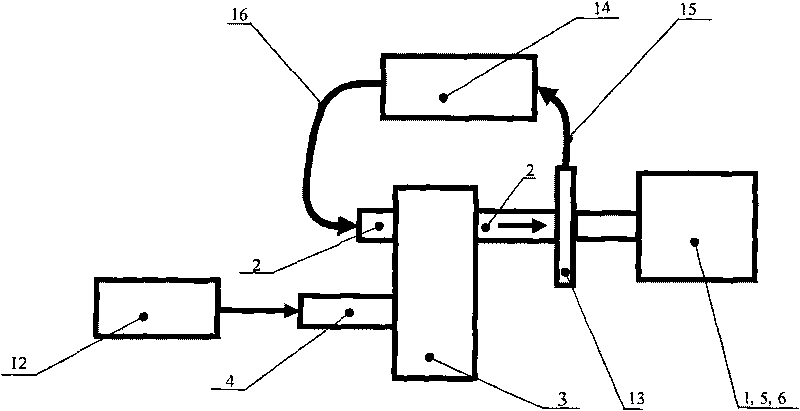

[0016] The present invention is specifically realized by an energy pick-up and release device installed on the output shaft of the intermittent motion mechanism that provides the motion-stop motion mode, and its principle is as follows: figure 2 shown. Before the energy pick-up and release device based on the present invention is installed, the drive motor (12) of the intermittent motion mechanism drives the input shaft (4) of the intermittent motion mechanism, and the inertial load (6) is driven by the output shaft (2). The energy pick-up and release device (14) based on the method of the present invention picks up the kinetic energy of the inertial load in the deceleration section of the intermittent motion mechanism through the expansion sleeve (13) and the path (15) and stores it in the form of elastic potential energy; In the stage, the energy pick-up and release device (14) converts the elastic potential energy into the drive torque for the output shaft (2) of the indire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com