Electronic control auxiliary wood board cutting device

A technology of wood cutting and cutting, applied in wood processing equipment, special forming/shaping machines, manufacturing tools, etc., can solve the problems of increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

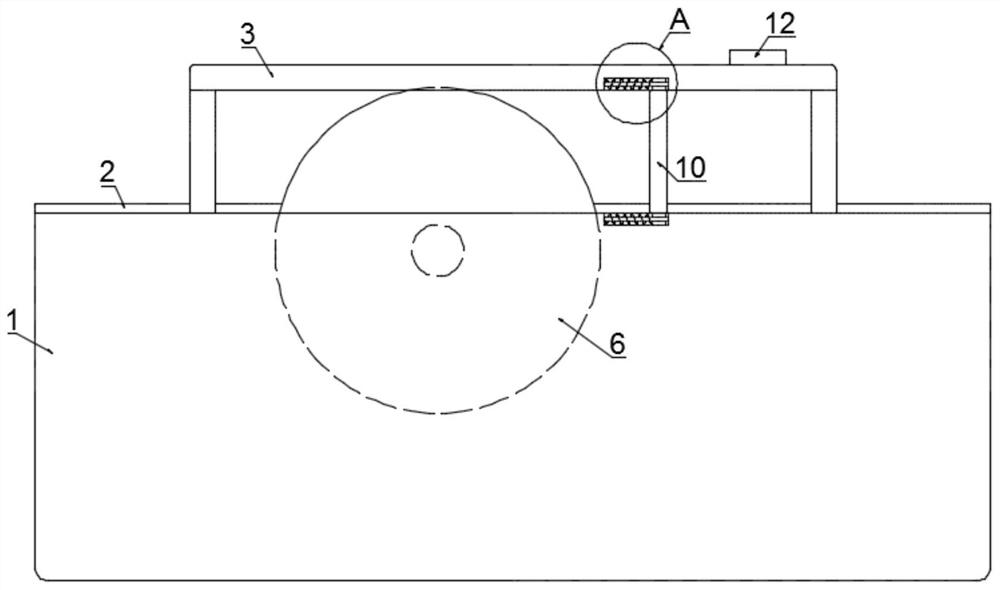

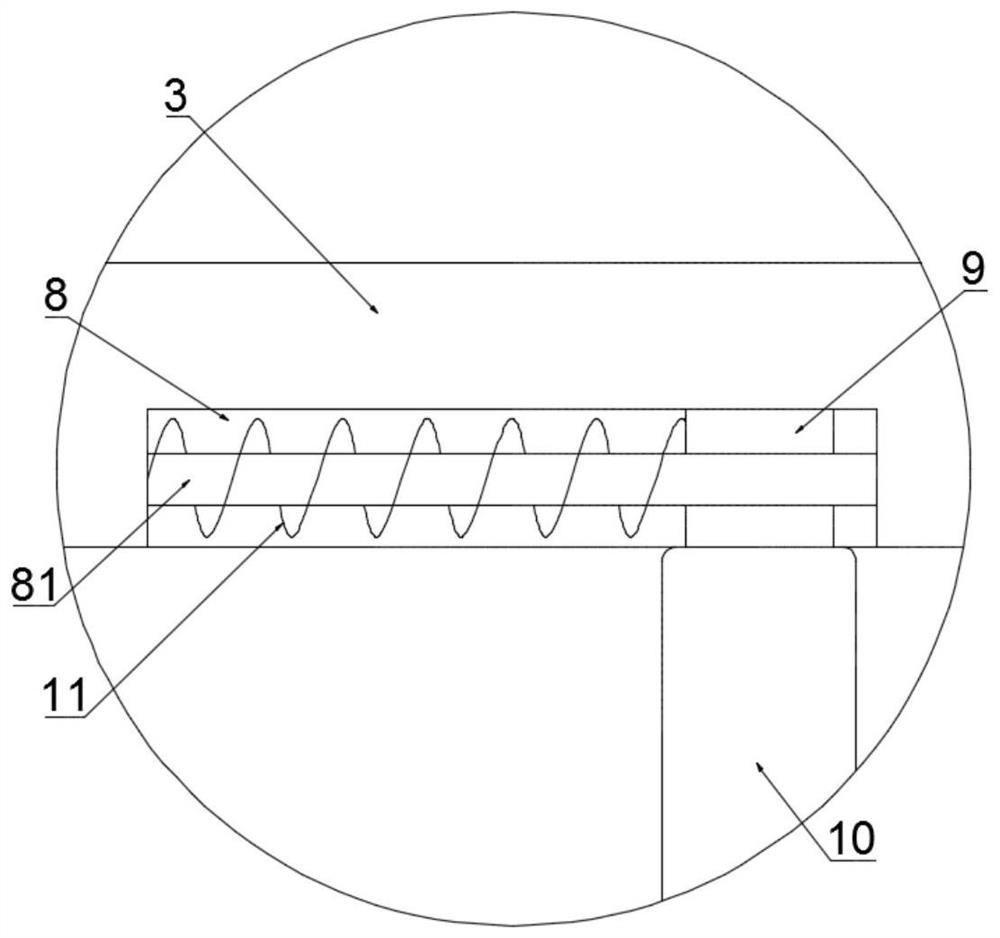

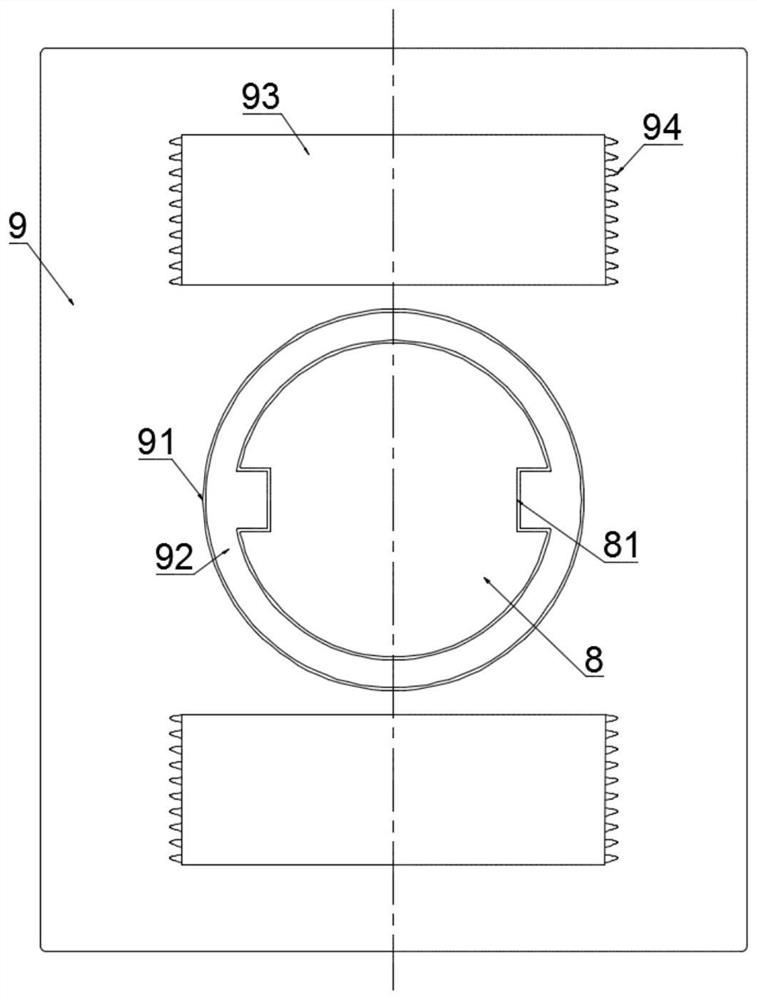

[0026] refer to Figure 1-5 , an electronically controlled auxiliary wood board cutting device, comprising a base 1, a conveyor belt 2 and a protective cover 3 are installed on the base 1, wherein the two ends of the protective cover 3 are provided with openings for the conveyor belt 2 and the wooden board to be processed to enter and exit, and the conveyor belt 2 to transmit the wood board to be processed, and the protective cover 3 separates the internal components from the outside world.

[0027] The base 1 is fixedly connected with the driving device 4, the driving device 4 adopts the existing driving motor and belt transmission mode, the output end of the drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com