Ultra-low temperature ball valve

A technology for ultra-low temperature and ball valves, applied in valve details, valve devices, shaft seals, etc., can solve the problems that rubber O-rings cannot be used at minus 196°C, rubber O-rings cannot withstand high temperatures or ultra-low temperatures, and cannot withstand switches, etc. , to achieve the effect of novel structure design, long service life and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

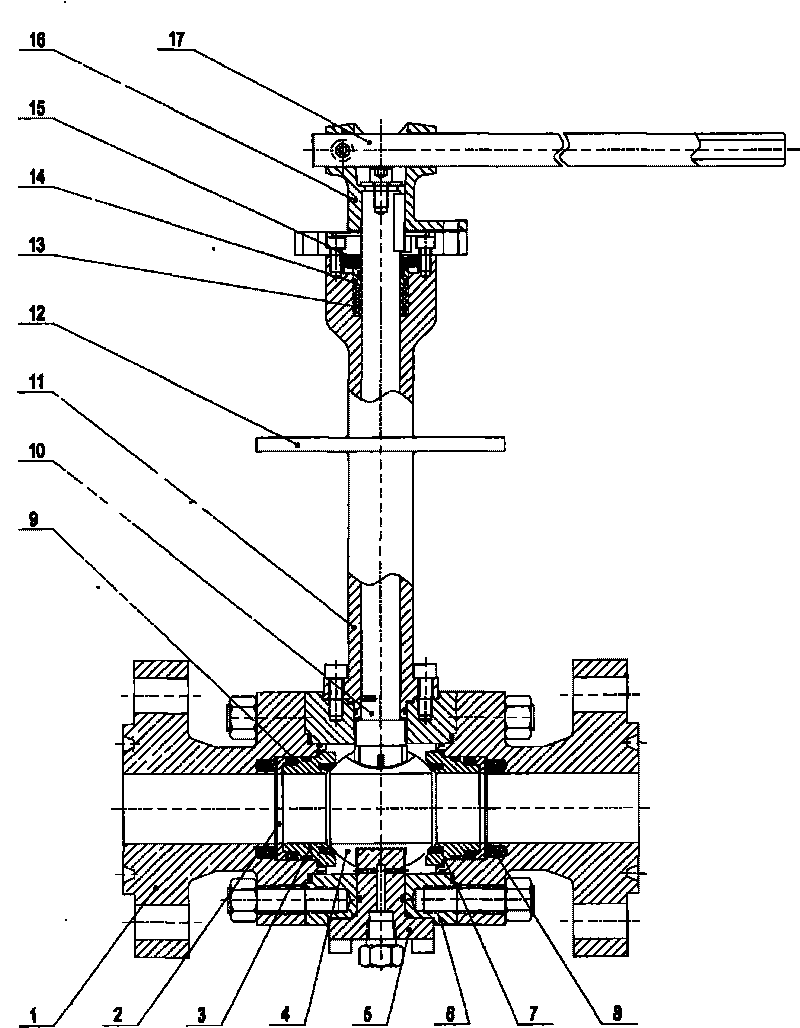

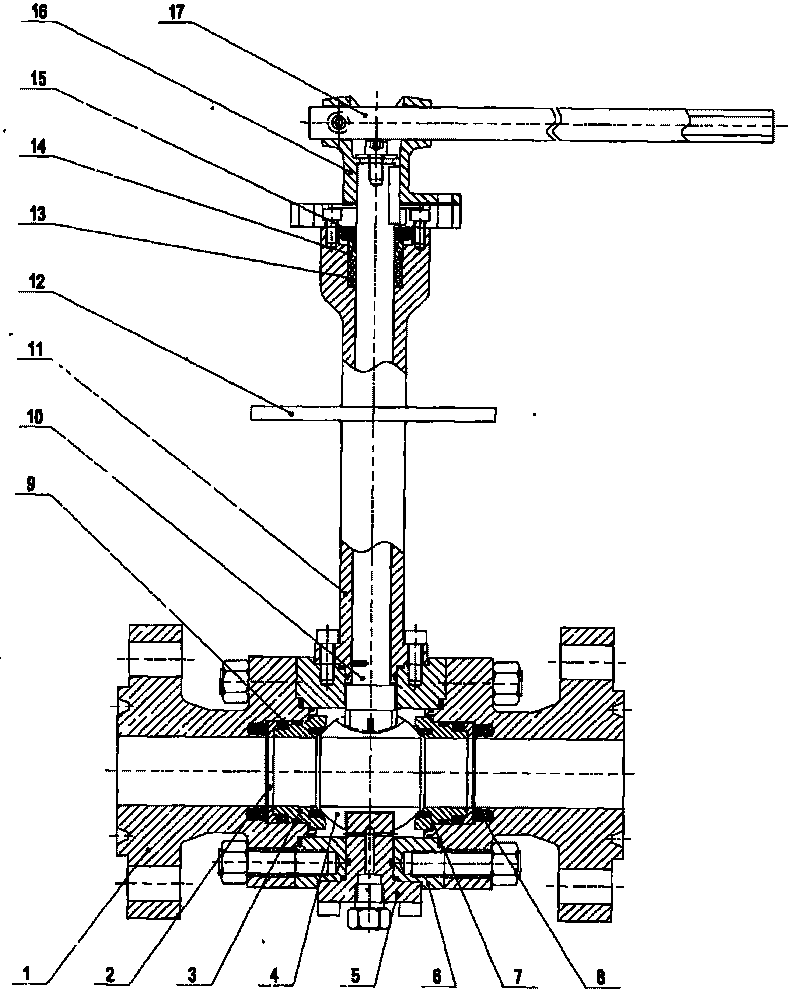

[0018] figure 1 It is a structural schematic diagram of an embodiment of the present invention.

[0019] like figure 1 Shown: ultra-low temperature ball valve, including valve body 6, valve cover 1, valve seat 3, ball 4, valve stem 10, three-way handle 16 and handle steel pipe 17, wherein ball 4 is located in the middle of valve body 6, valve cover 1 is located in the valve The two sides of the body 6 are fixedly connected with the valve body 6 by bolts, and the valve seat 3 is arranged between the valve cover 1 and the ball 4, and the retaining ring 2, the valve seat spring 8 and the resistance Pressure sealing ring 9 at minus 196°C, in which seat spring 8 is located between retaining ring 2 and valve cover 1, while pressure sealing ring 9 is located between retaining ring 2 and valve seat 3, between valve seat 3 and ball A sealing ring 7 resistant to a low temperature of minus 196° C. is arranged between the 4 to achieve double sealing, and the lower part of the sphere 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com