Expansion/shrinkage stress testing device for cement-based material

A cement-based material and testing device technology, applied in the direction of material inspection products, etc., can solve problems such as insufficient constraints, affecting calculation results, and difficult to repeat positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

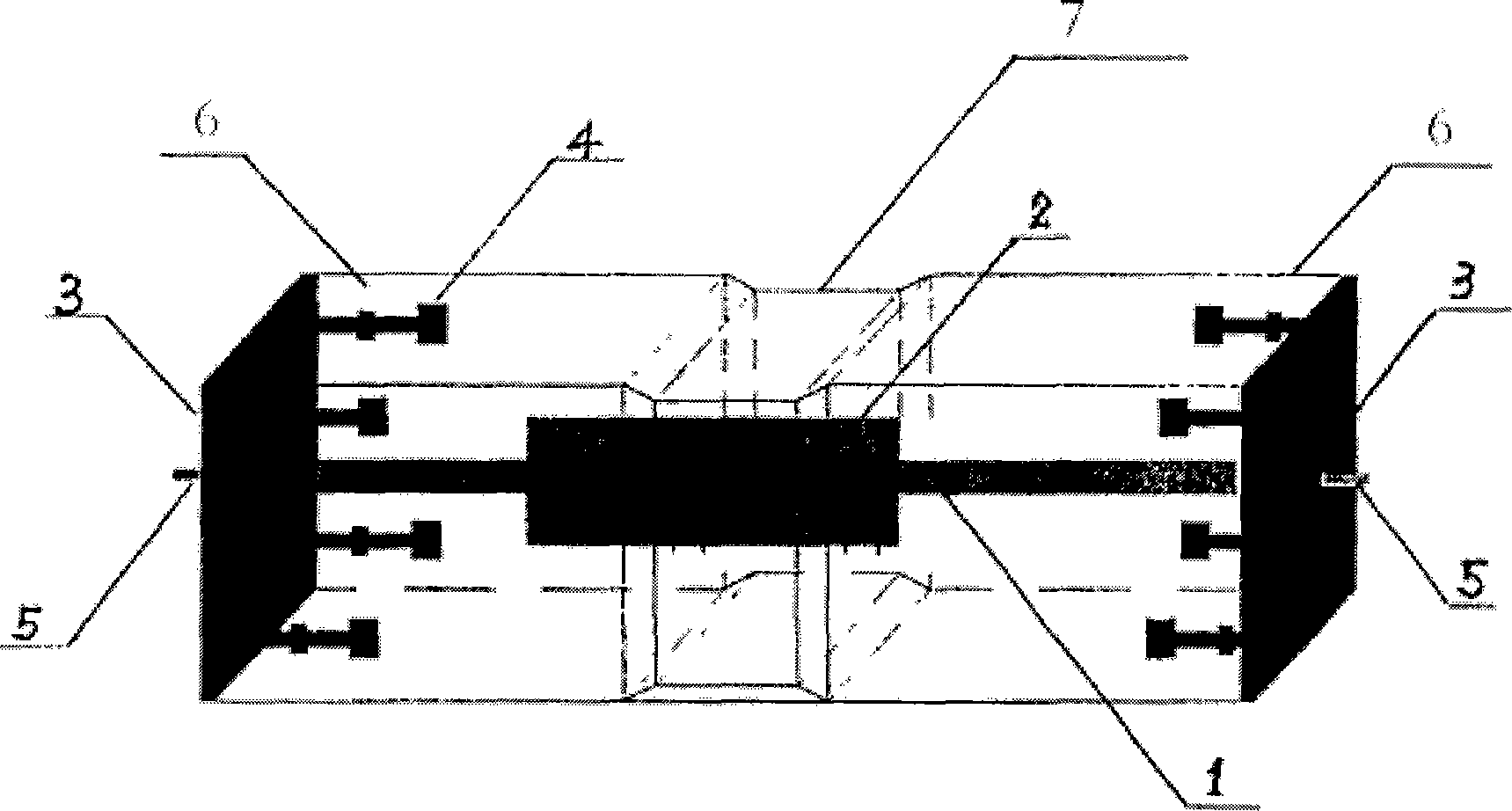

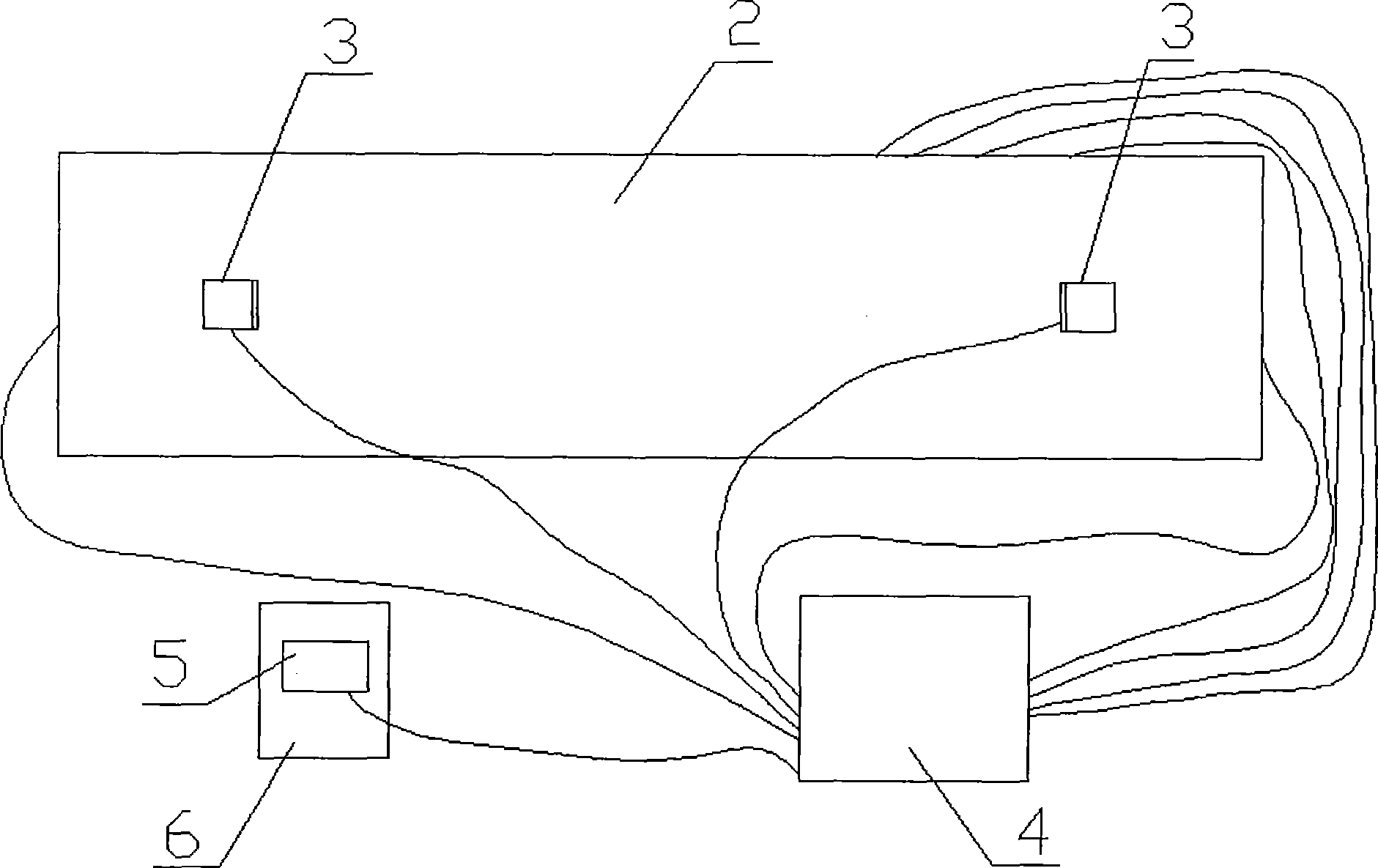

Method used

Image

Examples

Embodiment 1

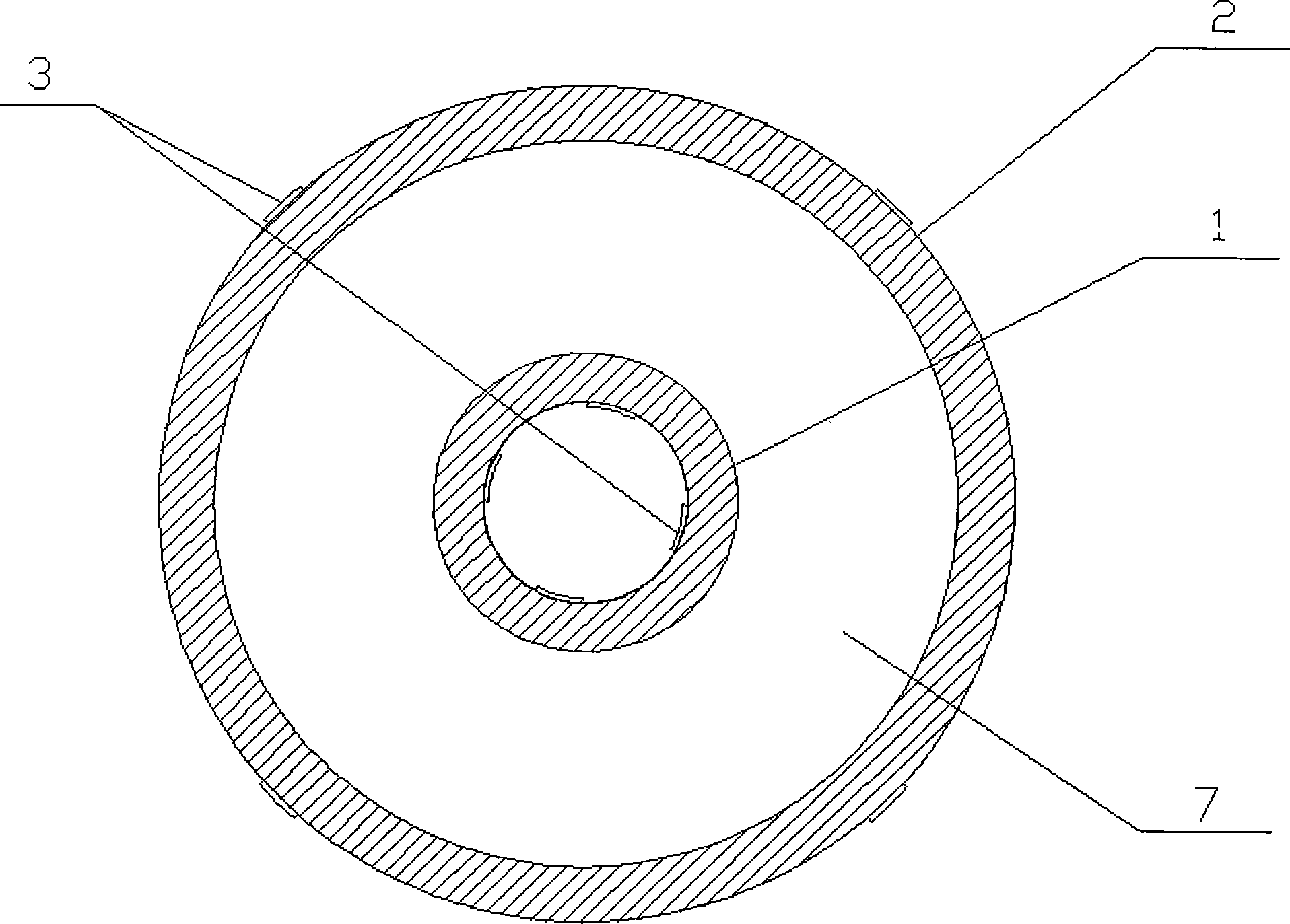

[0069] 1: Basic parameters of the test

[0070] The ring material is low carbon steel, the modulus of elasticity is 206GPa, and Poisson's ratio is 0.3.

[0071] Ring size is R 1 =52mm,R 2 =60mm,R 3 =85mm,R 4 =95mm, b=t=25mm.

[0072] The test proportion (clean pulp) is as follows:

[0073] Table 2 test mix ratio (kg / m 3 )

[0074]

[0075] In Table 2, KB is the benchmark specimen (elastic modulus 20GPa, Poisson’s ratio 0.2), PZJ is the specimen mixed with expansion agent (elastic modulus 18GPa, Poisson’s ratio 0.2), the test environment conditions are 20°C, 60% relative humidity.

[0076] 2: Test results and analysis

[0077] Figure 4 It is the steel ring strain of C50-KB group. For the net slurry KB, the outer ring is not subject to external force, which is basically 0, and the inner ring is under pressure, so it is a negative strain. At 4.2 days, the strain of the inner ring changes abruptly, which characterizes the first cracking time of the specimen.

[00...

Embodiment 2

[0084] 1: Basic parameters of the test

[0085] The ring material is Invar steel, with an elastic modulus of 160GPa and a Poisson's ratio of 0.3.

[0086] Ring size is R 1 = 100mm, R 2 =115mm, R 3 =145mm, R 4 =160mm, h=t=75mm.

[0087] The concrete test ratio is as follows (aggregate particle size 5mm-10mm):

[0088] Table 4 Example 2 concrete mix ratio (kg / m 3 )

[0089]

[0090] In Table 4, KB is the benchmark concrete specimen (elastic modulus 30GPa, Poisson’s ratio 0.2), PZJ is the concrete specimen mixed with expansion agent (elastic modulus 28GPa, Poisson’s ratio 0.2), and the test environment conditions are 20°C, 35 % relative humidity, the surface is covered with ethylene plastic film for 2.5 days of moisture-proof curing, and then dried at 35% relative humidity.

[0091] Figure 7 is the steel ring strain of concrete KB group. Within 2.5 days, the strain of the inner ring and the outer ring is basically 0, that is, the concrete has not deformed significan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com