High-power laser diffraction type spatial filter

A spatial filter, laser diffraction technology, applied in optics, instruments, optical components, etc., can solve the problems of two-way, two-axis spatial filtering, formation of harmful plasma, burning pinholes, etc., to improve the selection of angular spectrum performance, wide bandwidth, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

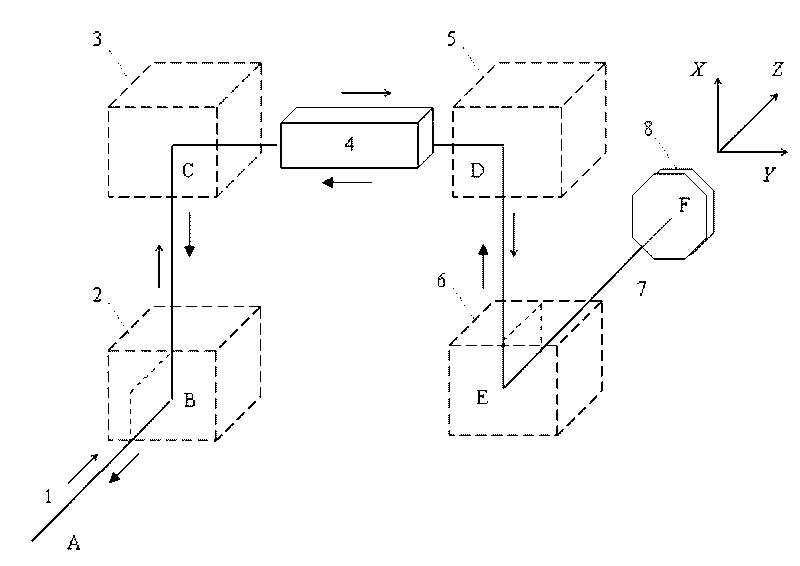

[0022] Example 1: High Power Laser Diffraction Filter

[0023] refer to figure 1 : In the filter device, on the left is an interstage isolation filter with the central axis as the vertical line BC, in the middle is a group of gain media with the central axis as the horizontal line CD, and on the right is a multi-pass cavity with the central axis as the vertical line DE For the filter, the central axis of the whole device forms a BCDEF folded line, and a separate volume Bragg grating that deflects the beam by 90° is placed at points B, C, D, and E, and a reflector is placed at point F mirror.

[0024] Among them, the interstage isolation filter is composed of two gratings (grating 2, grating 3). The multi-pass cavity filter consists of two gratings (grating 5, grating 6) and a mirror 8.

[0025] Spatial filtering using angular spectral selectivity of volume Bragg gratings. Under the action of the reflector, the laser is figure 1 The forward and reverse round trips in the d...

Embodiment 2

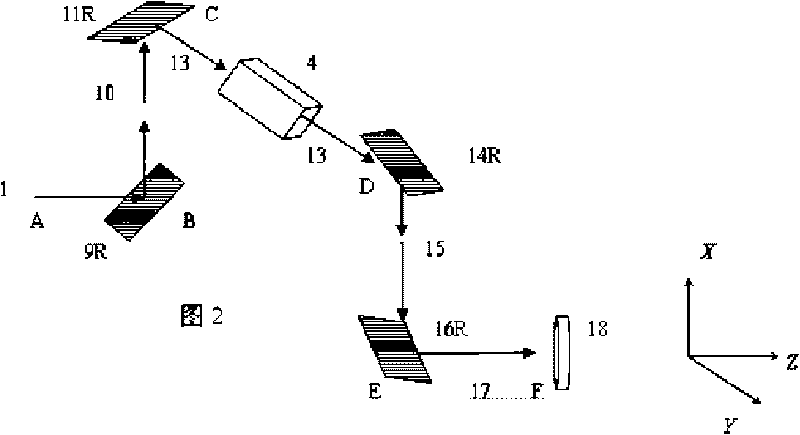

[0030] Embodiment 2: Class I filter composed of reflective grating

[0031] The volume Bragg grating used in this example is the "separated" grating described in claim 3, and the filtering device composed of the separated grating is called a type I device. The Class I device is characterized by figure 2 The lengths of the axes BC and DE in the center are greater than twice the cross-sectional diameter d (or side length L) of the gain medium. There is no lens in the entire optical path, and the beam has no convergence point in the filter.

[0032] The split grating used in this example is a single-period grating, and the operating state is reflective. The reflective state is characterized by the diffracted light being on the same side of the grating body as the incident light. Raster-Vector Orthogonal Two rasters are used in pairs. refer to figure 2 On the left, the interstage isolation filter consists of two volume Bragg gratings. The grating 9R is located at point B t...

Embodiment 3

[0038] Embodiment 3: Class I filter composed of a transmission grating

[0039] The volume Bragg grating used in this example is the "separated" grating described in claim 3. The split grating is a single-period grating operating in transmission mode. The characteristic of the transmission operation state is that the diffracted light and the incident light are located on different sides of the grating body. The structure of the transmissive grating type I spatial filter device is the same as that of the reflective grating device in Embodiment 2 above, and the beam propagation mode is the same.

[0040] refer to image 3 On the left, the interstage isolation filter consists of two volume Bragg gratings. The grating 9T is located at point B to deflect the beam 1 by 90° (propagating along the BC direction); the other grating 11T is located at point C to deflect the beam 10 by 90° (propagating along the CD direction). Light beam 12 leads to gain medium 4 .

[0041] refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com