Collector plate for all-vanadium redox flow battery

A flow battery, vanadium oxidation technology, applied in fuel cells, battery electrodes, circuits, etc., can solve problems such as the inability to meet the high efficiency of vanadium batteries, and achieve excellent corrosion resistance, strong tensile and strain resistance, and excellent mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

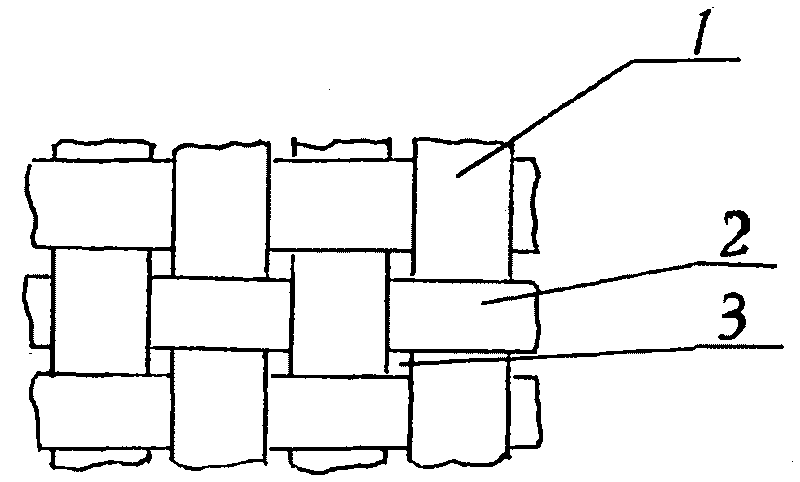

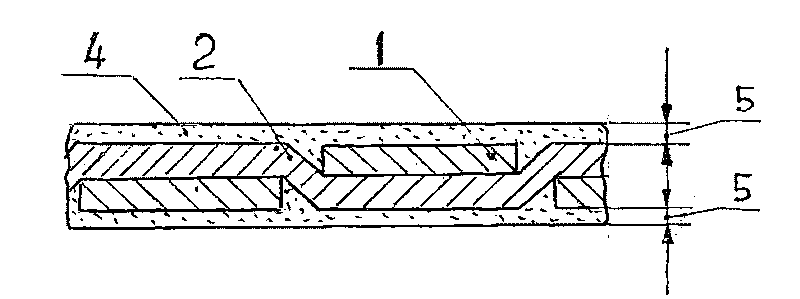

[0025] A current collecting plate made of a composite of single-layer carbon fiber cloth and conductive plastic (4). See figure 1 with figure 2 , the width of the longitudinal carbon fiber bundle (1) and the weft carbon fiber bundle (2) of the carbon fiber cloth used are both 2.8mm, and the thickness is 0.25mm; the warp direction carbon fiber bundle (1) and the weft direction carbon fiber bundle (2) The tensile strength is ≥ 2.5Gpa, and the tensile modulus is ≥ 220Gpa; the area of the uniformly distributed holes (3) of the carbon fiber cloth is 0.25mm 2 . The volume resistivity of the conductive plastic (4) adopted is 2×10 -1 Ω·cm. The thickness (5) of the layer of conductive plastic (4) on both sides of the collector plate is 0.1mm. The volume resistivity of the plane vertical direction of the carbon fiber cloth and the conductive plastic (4) composite current collector made under the above-mentioned conditions is 6 × 10 -2 -7×10 -2 Ω·cm. The tensile strength in th...

Embodiment 2

[0027] A current collecting plate made of a composite of single-layer carbon fiber cloth and conductive plastic (4). See figure 1 with figure 2 , the width of the longitudinal carbon fiber bundle (1) and the weft carbon fiber bundle (2) of the carbon fiber cloth used are both 2.8mm, and the thickness is 0.25mm; the warp direction carbon fiber bundle (1) and the weft direction carbon fiber bundle (2) The tensile strength is ≥ 2.5Gpa, and the tensile modulus is ≥ 220Gpa; the area of the uniformly distributed holes in the carbon fiber cloth is 0.25mm 2 . The volume resistivity of the conductive plastic (4) adopted is 1×10 -1 Ω·cm. The thickness (5) of the layer of conductive plastic (4) on both sides of the collector plate is 0.1mm. The carbon fiber cloth and the conductive plastic (4) composite current collecting plate prepared under the above-mentioned conditions have a volume resistivity of 3 × 10 in the vertical direction of the plane. -2 -4×10 -2 Ω·cm. The tensile...

Embodiment 3

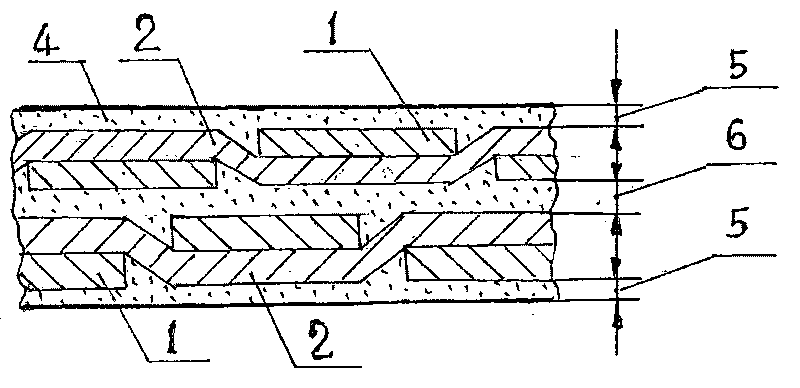

[0029] A current collecting plate made of double-layer carbon fiber cloth and conductive plastic (4). See figure 1 with image 3 , the width of the carbon fiber bundles (1) and the weft carbon fiber bundles (2) of the carbon fiber cloth used is 2.8mm, and the thickness is 0.25mm; Tensile strength ≥ 2.5Gpa, and its tensile modulus ≥ 220Gpa; the area of carbon fiber cloth uniformly distributed holes (3) is 0.25mm 2 . The volume resistivity of the conductive plastic (4) adopted is 2×10 -1 Ω·cm. The thickness (5) of the conductive plastic (4) layer on both sides of the current collector plate is 0.1mm; the thickness (6) of the conductive plastic (4) layer between the two layers of carbon fiber cloth is 0.2mm. The carbon fiber cloth and the conductive plastic (4) composite current collector made under the above conditions have a resistivity of 6 × 10 in the vertical direction of the plane. -2 -7×10 -2 Ω·cm. The tensile strength in the plane direction is ≥0.8Gpa. The tens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com