Delayless control method of rotor current of grid-connection, speed-change and constant-frequency double-fed induction wind driven generator

A wind turbine, rotor current technology, applied in wind power generation, single grid parallel feeding arrangement, multi-phase network asymmetry reduction, etc., can solve the problem that the circuit cannot distinguish whether the grid voltage is balanced or unbalanced, and affects the dynamic control of the system. The performance and dynamic control effect are not ideal, to achieve the effect of improving the traversing (uninterrupted) operation ability, the control method is simple and easy to implement, and the dynamic response characteristics are good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

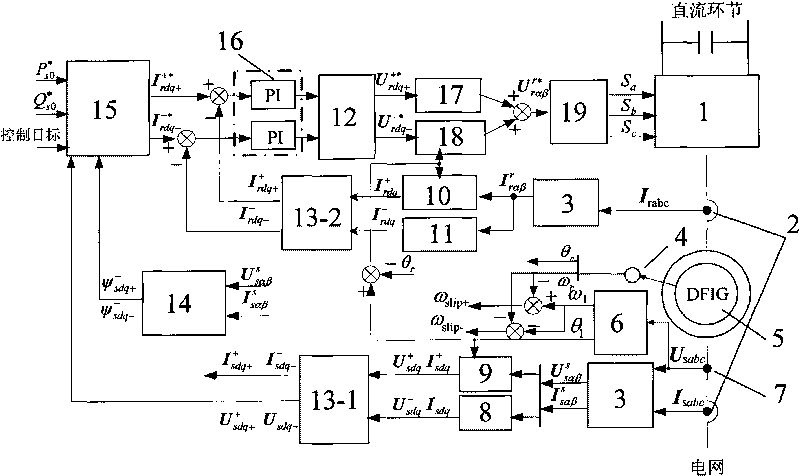

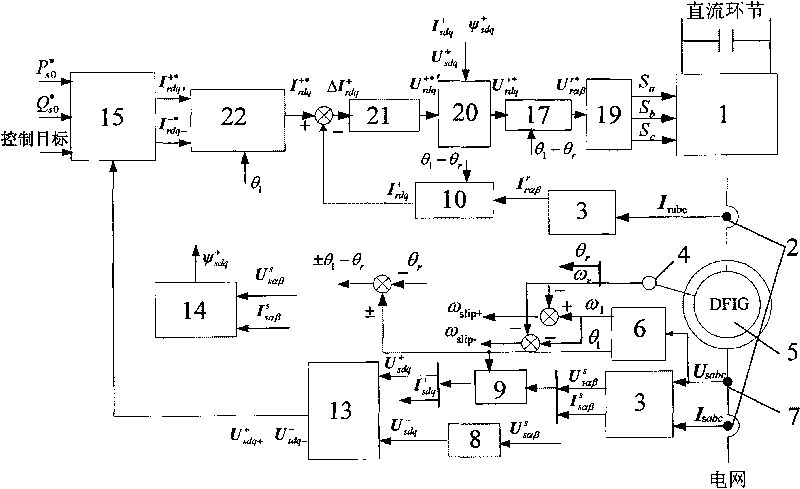

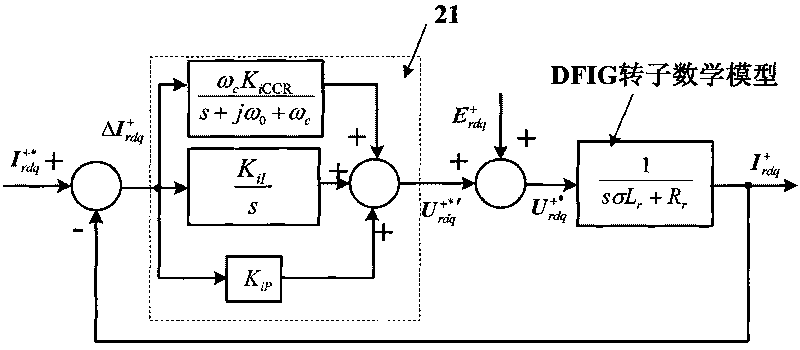

[0034] figure 2 It is a schematic diagram of the grid-connected variable-speed constant-frequency double-fed induction wind turbine rotor current control method without delay proposed by the present invention, including the control object DFIG5, and the rotor-side converter 1 (two-level or three-level) connected to the DFIG rotor level voltage type PWM inverter), Hall sensor 2 for three-phase stator and rotor current detection and Hall sensor 7 for three-phase stator voltage detection, encoder 4 for detecting DFIG rotor position and speed, and The control loop to realize the control target of DFIG under the condition of unbalanced grid voltage. The control loop is composed of a feedback signal processing channel and a forward control channel, wherein the feedback signal processing channel includes a software phase-locked loop (PLL) 6 for d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com