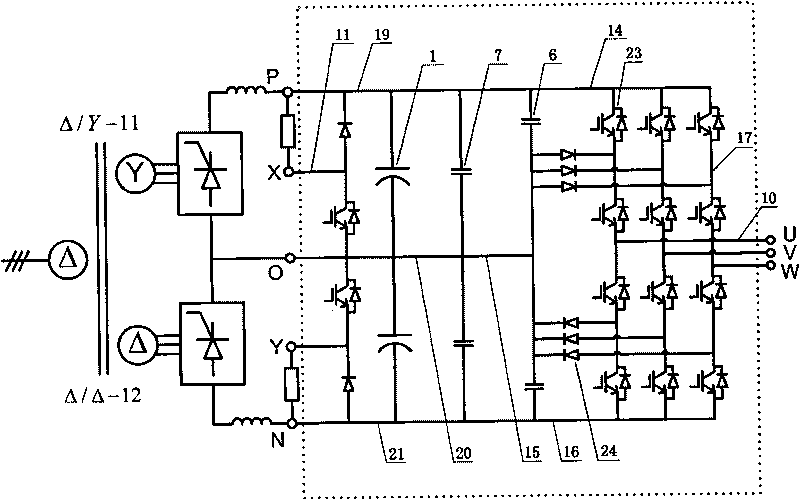

Water-cooled three-phase diode-clamped three-level inverted power module

A diode-clamped, three-level inverter technology is used in output power conversion devices, conversion of AC power input to DC power output, electrical components, etc. Uniformity and other issues to achieve the effect of improving power density, suppressing heat generation, and being easy to install and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

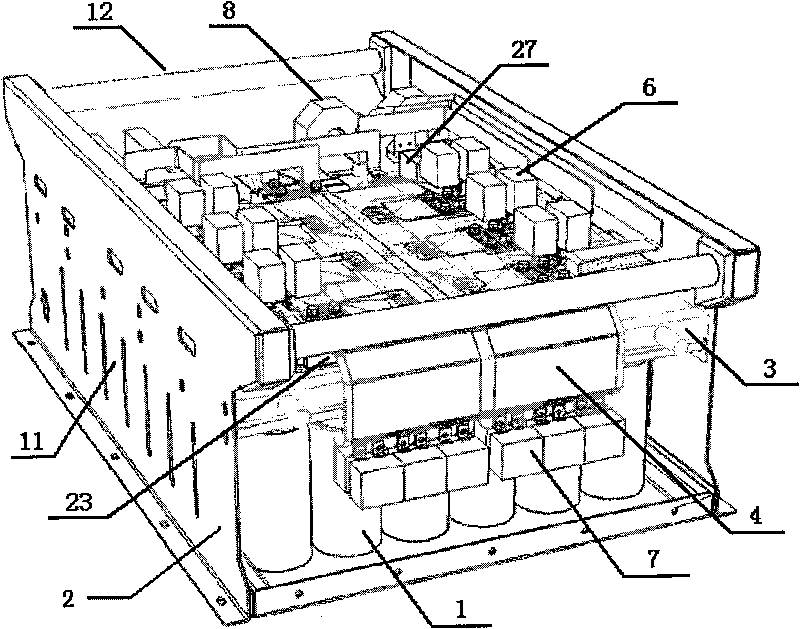

[0045] Such as image 3 , 4 , 7, 8, and 9, the water-cooled power module of the three-phase diode-clamped three-level inverter topology includes: a support frame 2 with a bottom steel plate at the bottom; an electrolytic capacitor bank 1 located on the bottom steel plate; The second laminated busbar 5 is laid on the electrolytic capacitor group 1, and the electrolytic capacitor group 1 is connected to each other through the second laminated busbar 5; the water-cooled radiator 3 is erected above the second laminated busbar 5; the first laminated busbar 5 The busbar 4 is erected above the water-cooled radiator 3, and the tooth-shaped connection terminals corresponding to the first laminated busbar 4 and the second laminated busbar 5 are respectively connected through the second absorbing capacitor group 7; the first absorbing capacitor Group 6 , located above the first laminated busbar 4 , is connected to the first laminated busbar 4 .

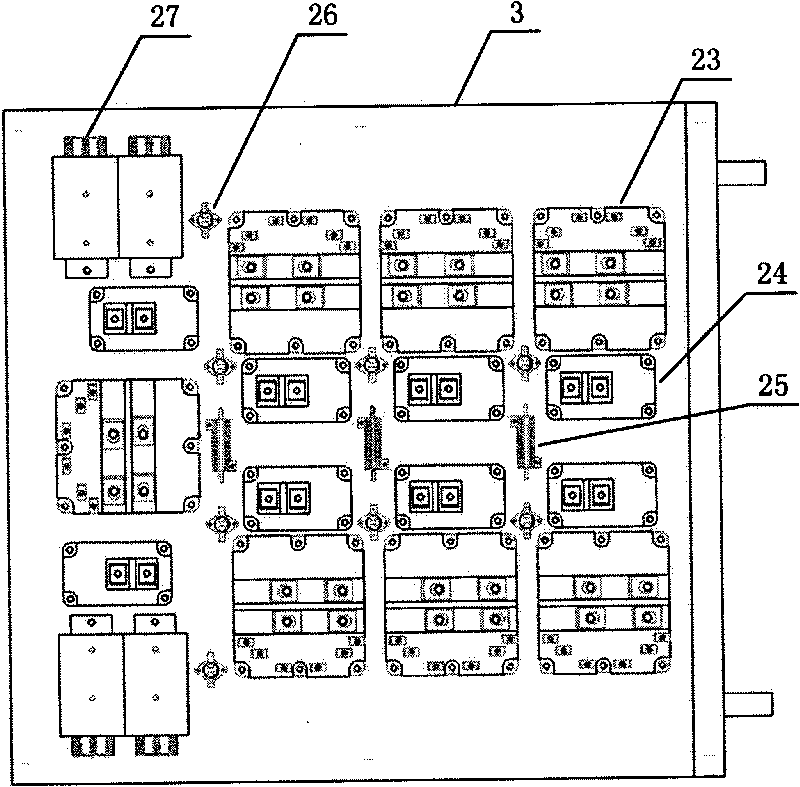

[0046] Such as figure 2 As shown, sev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com