Process for producing dripping water incense tea

A production process and technology of fragrant tea, which is applied in the field of production technology of dripping fragrant tea, can solve the problems of low efficiency of dripping fragrant tea processing equipment and technology, failure to meet the needs of consumers, and lack of tea, so as to improve the quality of appearance production, Ensure the technical requirements of clean processing and improve the effect of internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

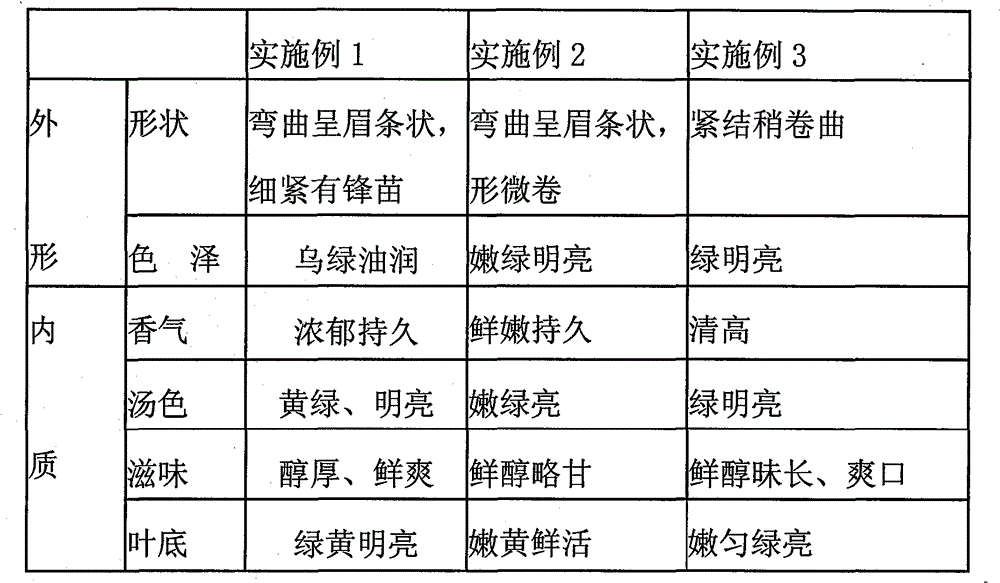

Examples

Embodiment 1

[0020] 1. Storage of fresh leaves at low temperature and constant humidity: put the picked fresh leaves with one bud and one leaf into the leaf storage box and put the leaf storage box into the leaf storage room. The temperature in the storage room is 2°C and the humidity is 85%. The time should be within 3 days;

[0021] 2. Synthetic de-enzyming: fresh leaves (or fresh leaves stored at low temperature and constant humidity) are sent to 6CSF500 synthetic de-enzyming machine through the belt elevator unit for de-enzyming. The temperature of the hot air is controlled at 300°C, and the temperature of the drum wall is controlled at 290°C. . The greening time is 2-3 minutes, so that the greening leaves are dark green and soft, the stems are broken continuously, and the moisture content of the greening leaves is about 65%.

[0022] 3. On-line low-temperature cooling: the green leaves are transported to the cooling machine through the air conveying equipment for cooling. The cooling...

Embodiment 2

[0033] 1. Storage of fresh leaves at low temperature and constant humidity: put the picked fresh leaves with one bud and two leaves into the leaf storage box and put the leaf storage box into the leaf storage room. The temperature in the storage room is 5°C and the humidity is 90%. The time should be within 4 days;

[0034] 2. Synthetic de-enzyming: fresh leaves (or fresh leaves stored at low temperature and constant humidity) are sent to 6CSF500 synthetic de-enzyming machine through the belt elevator unit for de-enzyming. The temperature of the hot air is controlled at 280°C, and the temperature of the drum wall is controlled at 270°C. . The greening time is 2-3 minutes, so that the greening leaves are dark green and soft, the stems are broken continuously, and the moisture content of the greening leaves is about 65%.

[0035] 3. On-line low-temperature cooling: the green leaves are transported to the cooling machine through the air conveying equipment for cooling. The cooli...

Embodiment 3

[0046] 1. Storage of fresh leaves at low temperature and constant humidity: put the picked fresh leaves with one bud and three leaves into the leaf storage box and put the leaf storage box into the leaf storage room. The temperature in the storage room is 8°C and the humidity is 93%. The time should be within 5 days;

[0047] 2. Synthetic de-enzyming: fresh leaves (or fresh leaves stored at low temperature and constant humidity) are sent to 6CSF500 synthetic de-enzyming machine through the belt elevator unit for de-enzyming. The temperature of the hot air is controlled at 260°C, and the temperature of the drum wall is controlled at 260°C. . The greening time is 2-3 minutes, so that the greening leaves are dark green and soft, the stems are broken continuously, and the moisture content of the greening leaves is about 65%.

[0048]3. On-line low-temperature cooling: transport the green leaves to the cooling machine through the air delivery equipment for cooling. The cooling tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com