Method for position finding and welding of protective plate, small foot and longitudinal beam for aluminum-magnesium alloy tanker by adopting robot

A welding robot and welding method technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems that the robot has no visual function, affects the work progress, and the welding quality cannot be better guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

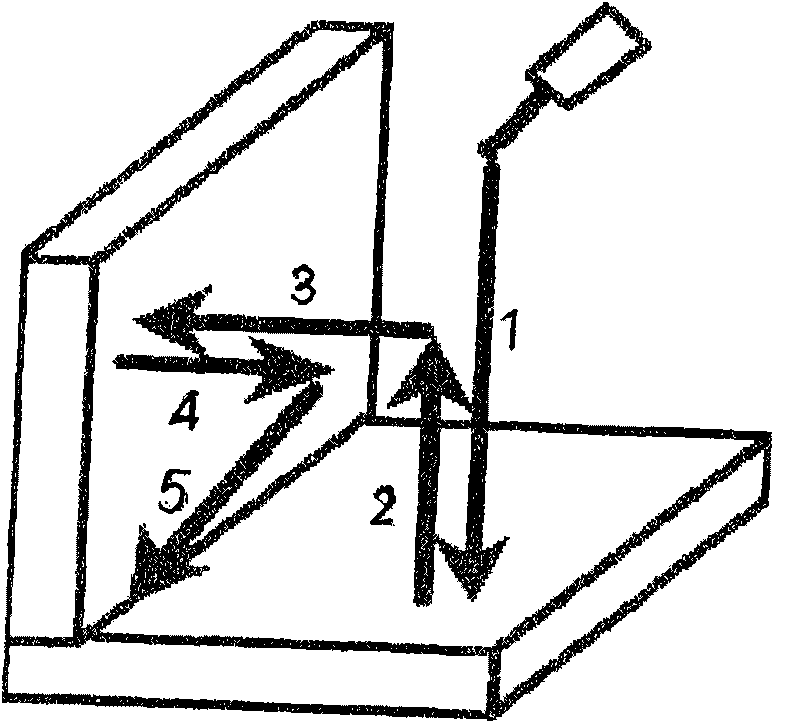

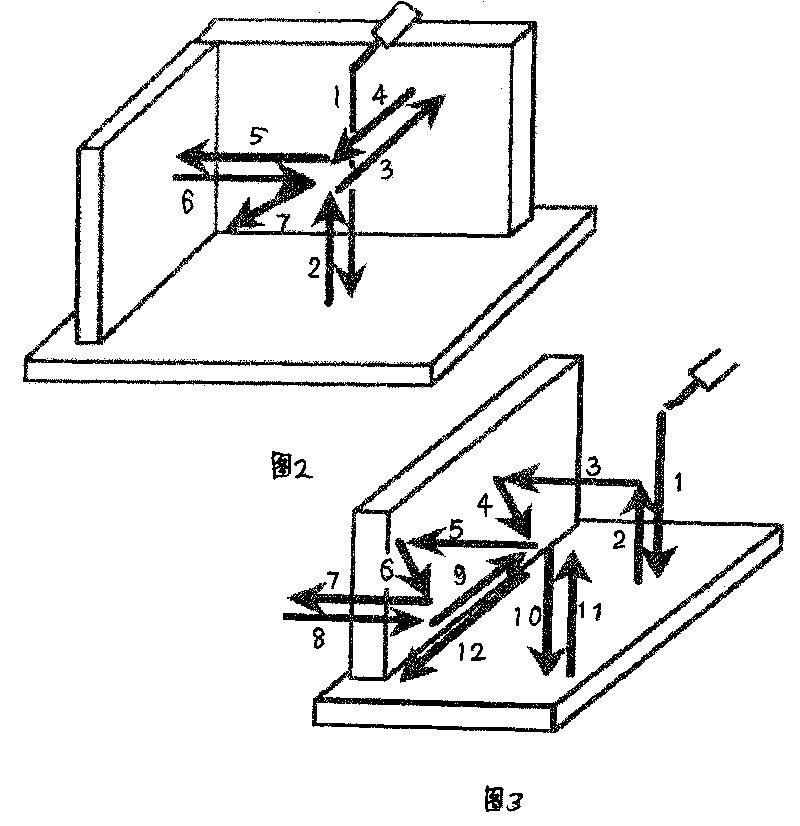

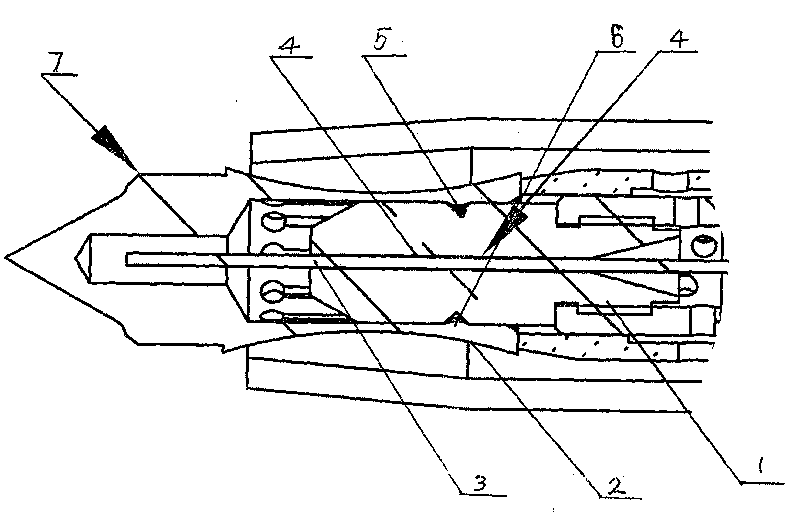

[0010] According to the accompanying drawings (such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown) the present invention is further described: aluminum, magnesium alloy tanker guard plate, small foot, longitudinal beam welding robot position-finding, welding method (such as figure 1 , figure 2 , image 3 Shown): The robot uses the high voltage between the welding wire and the workpiece to automatically move the trajectory according to the regulations of the program, measure the actual position of the workpiece, and calculate the deviation between the actual position of the workpiece and the measured position, and then the robot follows the correction In the specific work: aluminum, magnesium alloy tank car guard plate, small feet, longitudinal beam welding robot positioning, welding method when positioning at right angles (such as figure 1 Shown): The robot controls the welding wire in the welding torch to move through the two directions of 1 and 3, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com