Integrated vehicle lubrication device

An integrated, vehicle technology, applied in the field of vehicle lubrication system, can solve the problems of heavy component weight and large space size of the lubrication system, and achieve the effects of weight reduction, system function integration, and reliability improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

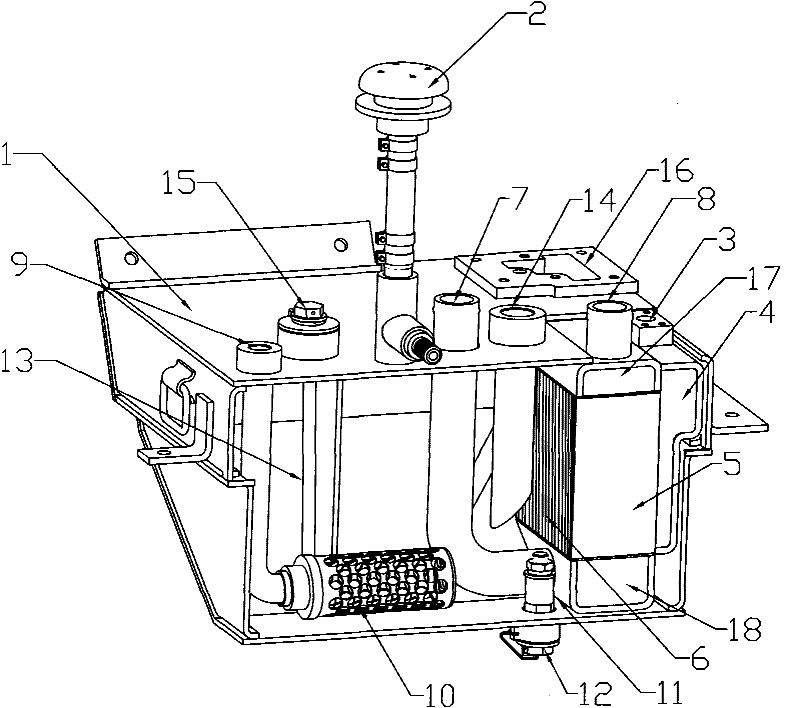

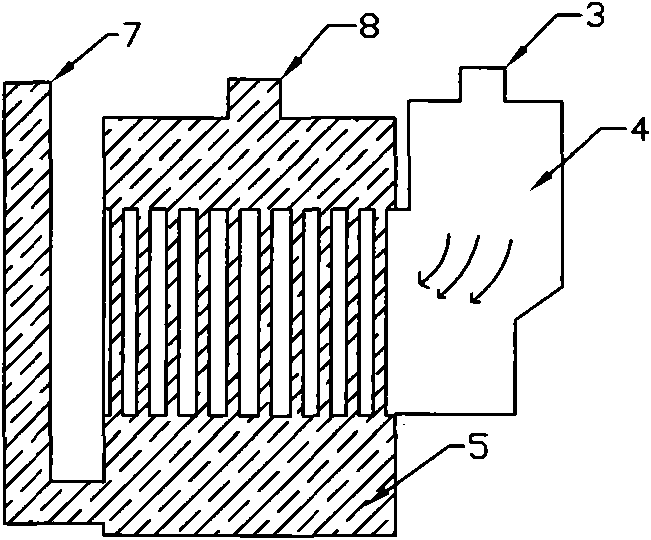

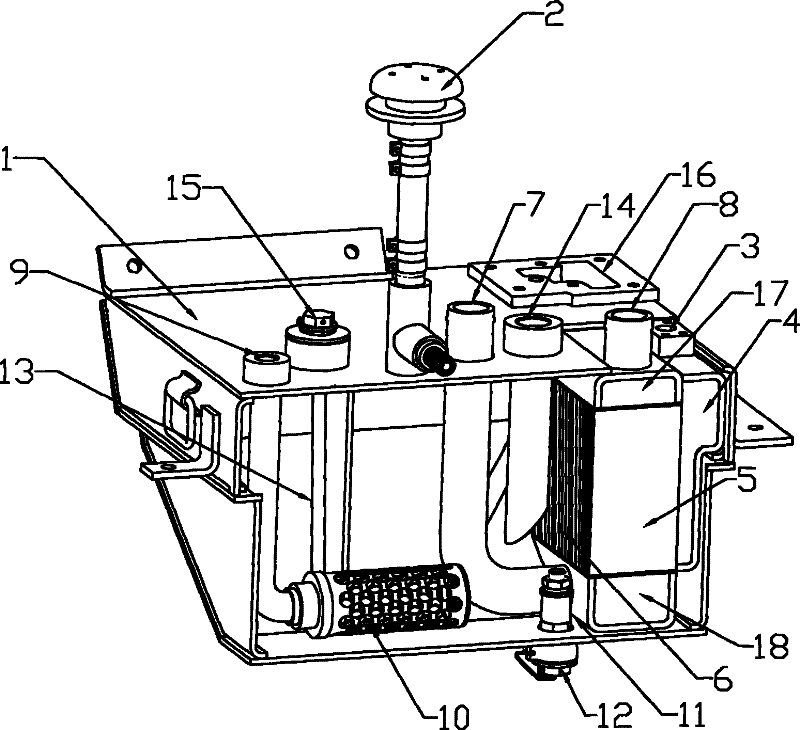

[0015] Such as figure 1 As shown, this solution welds a water-oil heat exchanger 5 in a lubricating oil tank 1, which can strengthen the rigidity of the entire lubricating box. It uses system circulating water to cool and preheat lubricating oil. The upper and lower ends of the core body 6 It is the water inlet chamber 17 and the water outlet chamber 18, the water inlet chamber 17 and the water outlet chamber 18 are equipped with the water inlet pipe 8 and the water outlet pipe 7 respectively, the core body 6 includes multi-layer heat dissipation fins and heat dissipation pipes, and the heat dissipation fins are installed on the heat dissipation pipes , the inside of the cooling pipe communicates with the water inlet chamber 17 and the water outlet chamber 18, the right end of the core body 6 is an oil chamber 4, and one end of the oil chamber 4 is equipped with an oil return interface 3, and the other end is connected with the core body. Breather 2 is installed on the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com