Brown colorant for water Teflon high-temperature cloth and preparing method thereof

A technology of coffee color and Teflon, which is applied in the direction of textiles, papermaking, fiber treatment, etc., can solve the problem of resistance to chemical media, color brightness can not meet the requirements, ordinary colorants are difficult to PTFE emulsion compatibility, Teflon surface is extremely To solve the problem of low stability, achieve good commercial value, low overall cost of coloring, and long storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

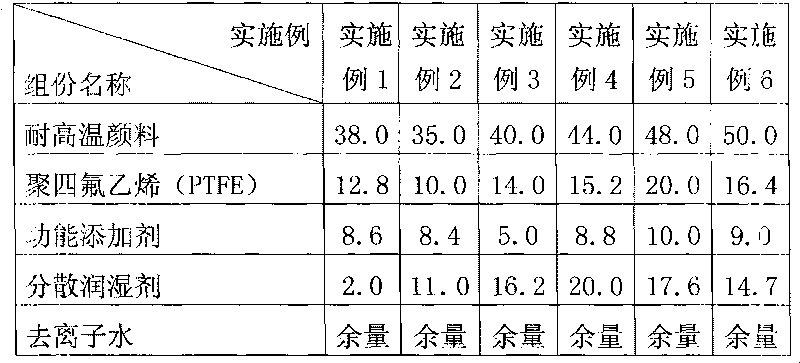

[0025] The formula of the embodiment of the invention is referring to Table 1:

[0026] Table 1: (unit: weight percentage)

[0027]

[0028] According to above-mentioned prescription, preparation method carries out as follows:

[0029] ①.Put deionized water and polytetrafluoroethylene into the dispersing tank and stir evenly, then add dispersing wetting agent, and disperse for 10 minutes at a speed of 400-600r / min to obtain the first mixed solution;

[0030] ②. Add the functional additive to the first mixed solution obtained in step ① and mix evenly to obtain the second mixed solution;

[0031] ③. During the stirring process, put the high-temperature-resistant pigment step by step into the second mixed solution obtained in step ② to obtain a coffee color pre-dispersed color paste;

[0032] ④. Disperse the coffee color pre-dispersed color paste obtained in step ③ at a speed of 2000-2500r / min for not less than 30 minutes to obtain a pre-mixed brown color paste;

[0033] ⑤....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com