Tripping method for operation by adopting power swivel and tool

A power swivel and tripping technology, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc., can solve the problems that the power swivel cannot be directly used for tripping, takes up a large space at the wellhead, and has a large labor intensity for workers. Wellhead tools, reduce labor intensity, increase the effect of transportability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

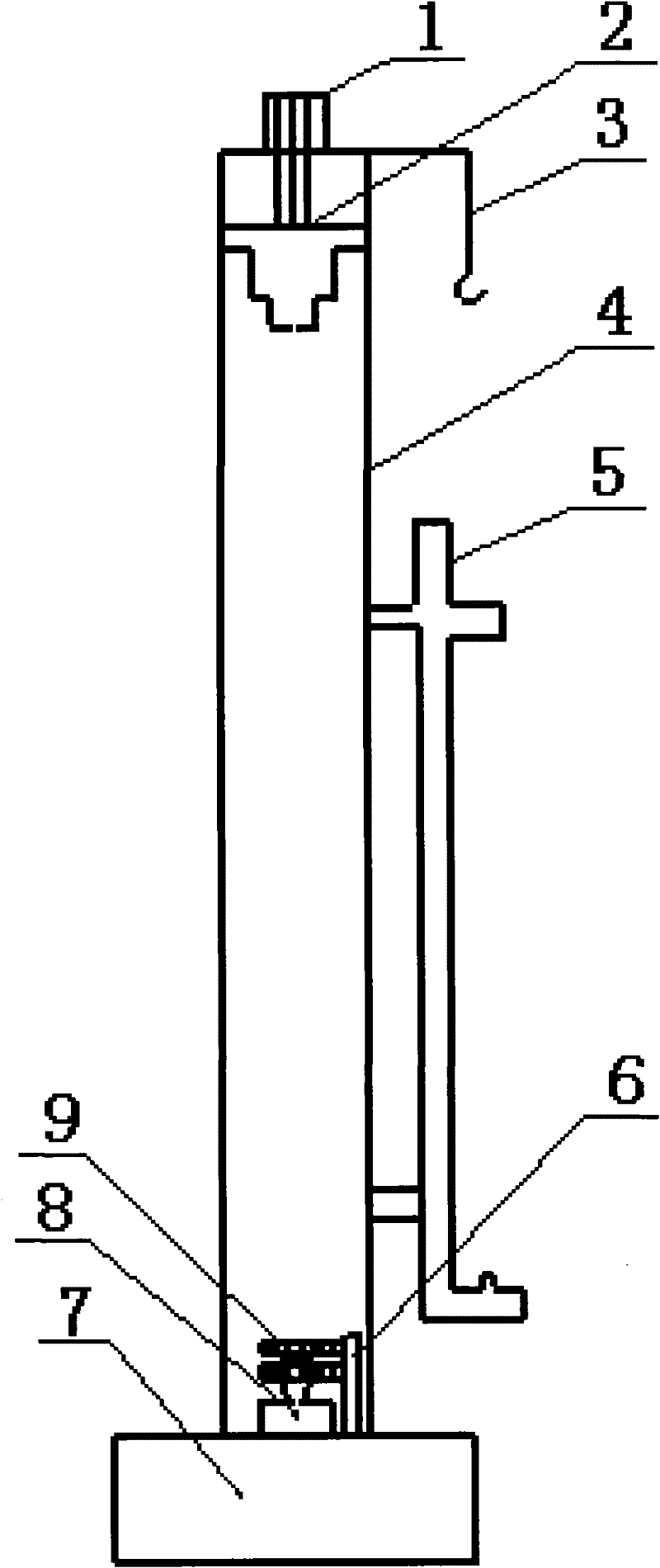

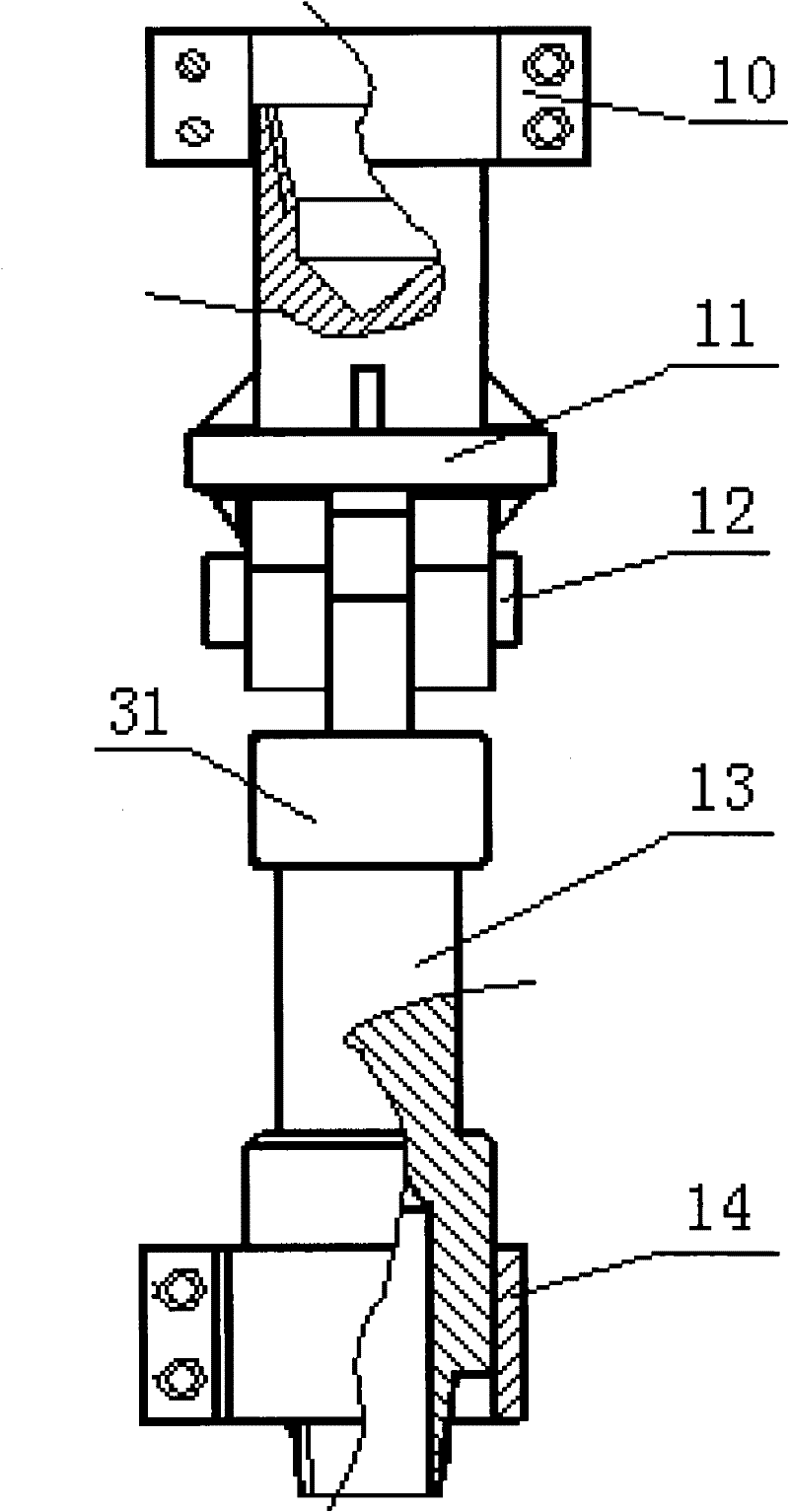

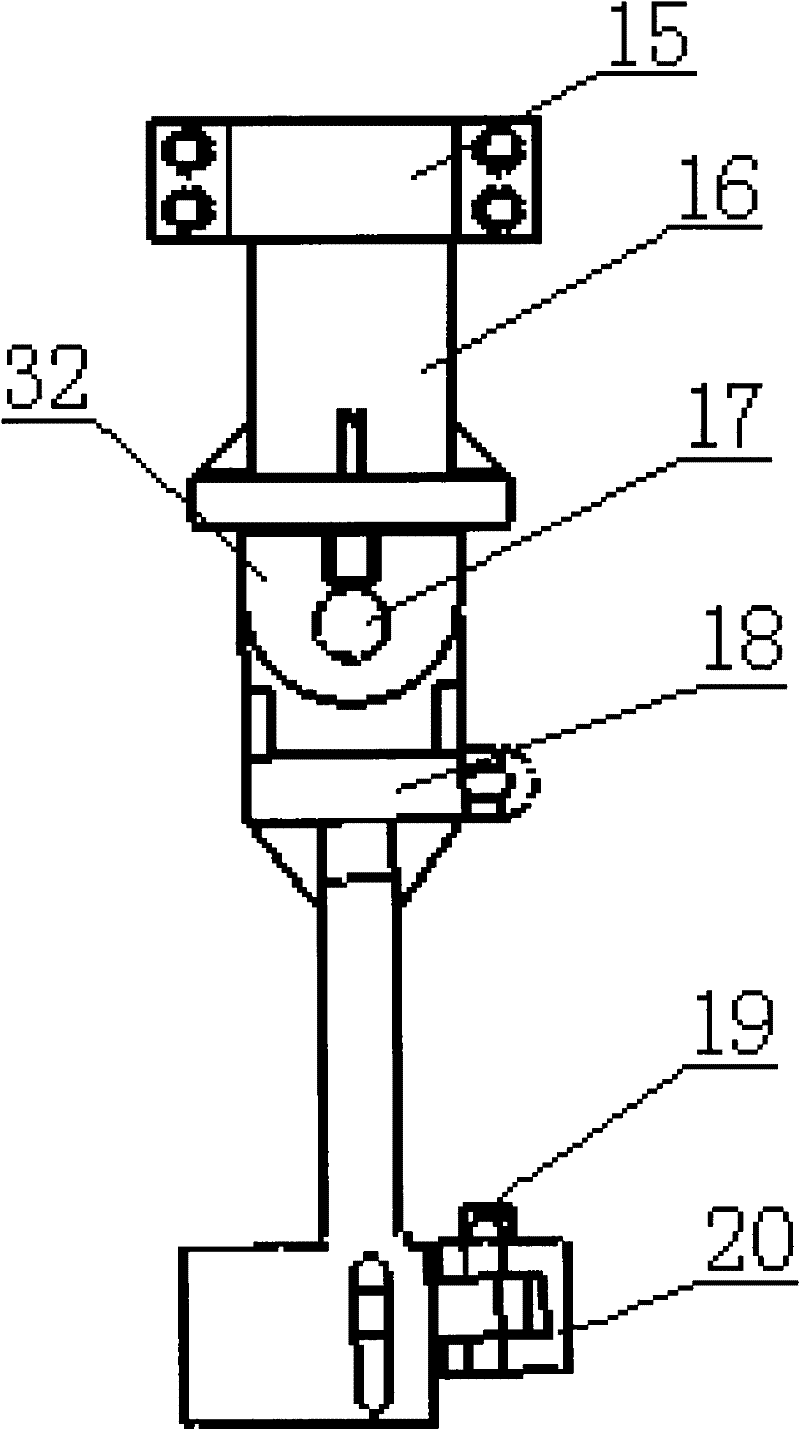

[0067] Embodiment 1: With a vehicle-mounted drilling rig equipped with J-1 power swivel 2, WA24A hydraulic power torsion chain tongs 6, and FG type power slips 8, drill collars with an outer diameter of 127 mm, drill pipes with an outer diameter of 127 mm, and a body with an outer diameter of 127 mm Taking the tripping operation of a casing with an outer diameter of 140 mm as an example, the present invention will be described in further detail.

[0068] refer to figure 1 . Check the performance status of existing equipment and standing wellhead tools. Including: crown block 1, power swivel 2, hydraulic winch 3, derrick 4, pipe string transmission device 5, hydraulic power torsion chain tongs 6, drill floor 7, power slips 8 and hydraulic small winch, and torsion-bearing Drill collar elevator 31 and torsion-bearing drill pipe, casing elevator 32.

[0069]The drill string tripping method includes three parts: the drill string tripping method, the drill string tripping method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com