Reduction box used for battery fork lift truck

A reduction box and forklift technology, applied in transmission boxes, differential gears, components with teeth, etc., can solve the problems of inconvenient installation of forklifts and large volume of reduction boxes, and achieve volume reduction and space utilization. Efficient and shortened effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

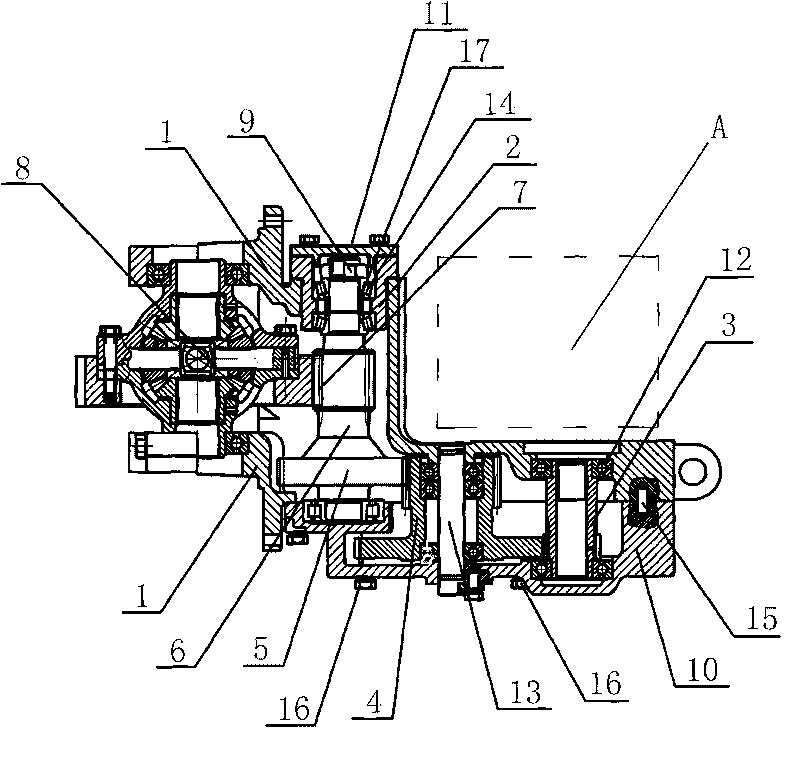

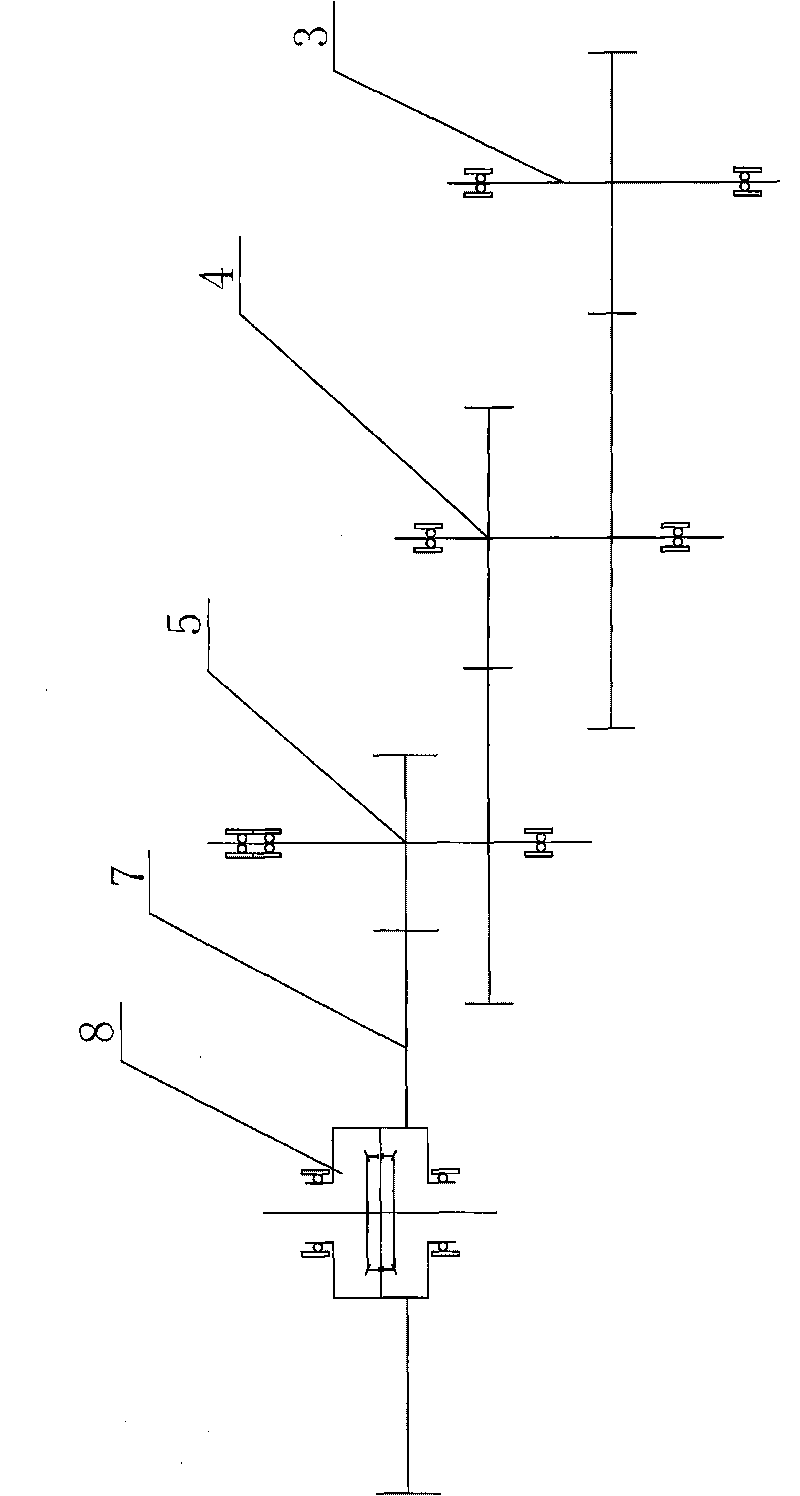

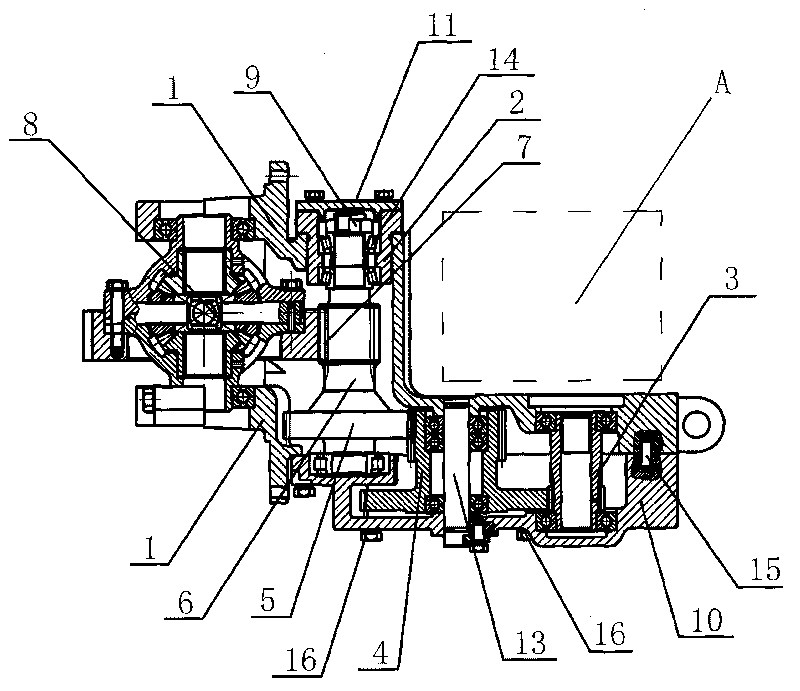

[0014] like figure 1 As shown, a reduction box for a battery forklift includes a box body 1, and an input gear 3 is arranged inside the box body 1, and the input gear 3 is connected to a duplex gear 4, and the duplex gear 4 is connected to the driving gear on the intermediate gear shaft 6 5. The intermediate gear shaft 6 is also provided with a driven gear 7, the driven gear 7 is connected to the external differential assembly, the case 1 is in the shape of an "L", and the intermediate gear shaft 6 and the input gear 3 are respectively arranged on the "L" "On both sides of the box. One end of the intermediate gear shaft 6 is covered with a tapered roller bearing 14, and the outer ring of the tapered roller bearing 14 is fixed on the bearing seat 2. The intermediate gear shaft 6 is sleeved with an adjusting nut 9 at one end where the tapered roller bearing 14 is housed, and the adjusting nut 9 presses the inner ring of the tapered roller bearing 14 . Two tapered roller bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com