Finger tip sealing device and the flexible constrictor

A technology of fingertip sealing and current limiting sheet, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of poor sealing performance, high processing cost, axial tilting of the finger body, etc., and achieve sealing Improved performance, low processing cost, and improved sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

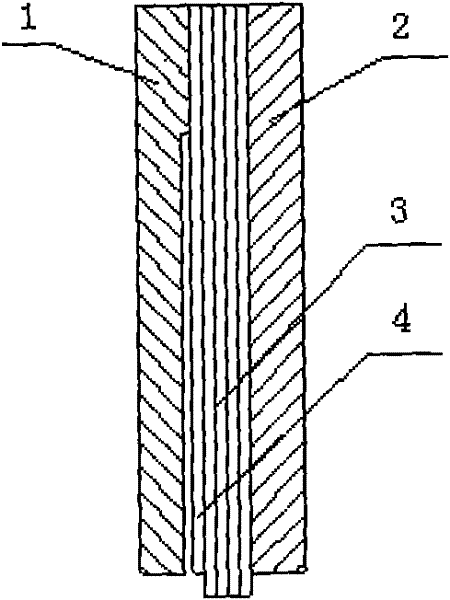

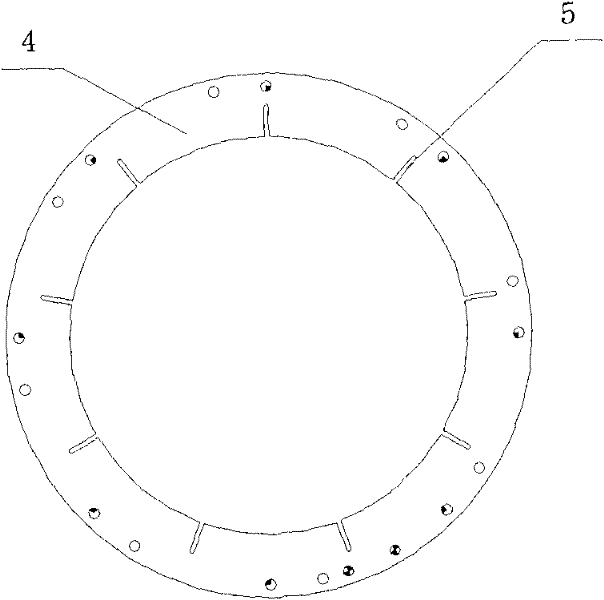

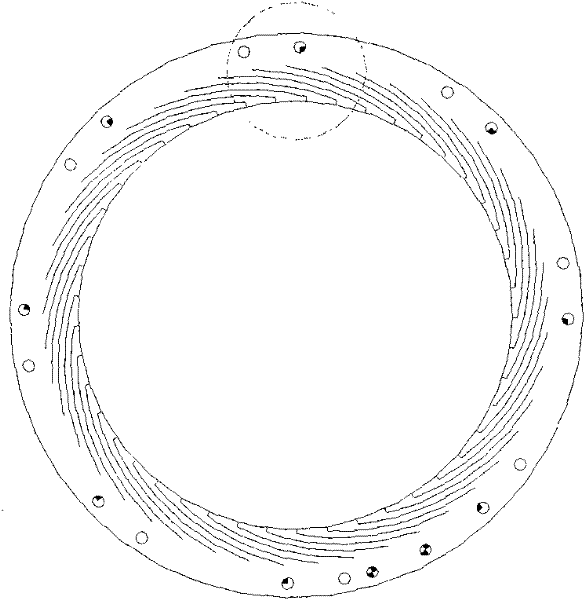

[0020] see figure 1 , which is a structural schematic diagram of a preferred embodiment of the fingertip sealing device of the present invention. In this embodiment, the fingertip sealing device includes a front baffle 1 , a flexible restrictor 4 , a fingertip 3 and a rear baffle 2 arranged in sequence. Wherein, the front baffle 1 and the rear baffle 2 are annular plate-shaped structures, the flexible flow limiting sheet 4 and the fingertip sheet 3 are also annular structures, and the outer peripheral edges of the flexible flow limiting sheet 4 and the fingertip sheet 3 are Pairs of assembly holes are arranged on the top, and the flexible current limiting sheet 4 is arranged alternately with the adjacent fingertip sheet 3 and the transfer holes of the fingertips of each fingertip sheet 3 during assembly, so as to have a better installation effect.

[0021] The fingertip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com