Heavy load absolute type multi-ring resolving encoder

An absolute encoder technology, applied in the direction of using electric/magnetic devices to transmit sensing components, etc., can solve the problems of photoelectric encoder damage, reliability decline, fragility, etc., to overcome mechanical wear and gap errors, and reduce reliability Sexuality and damage, the effect of overcoming axial impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

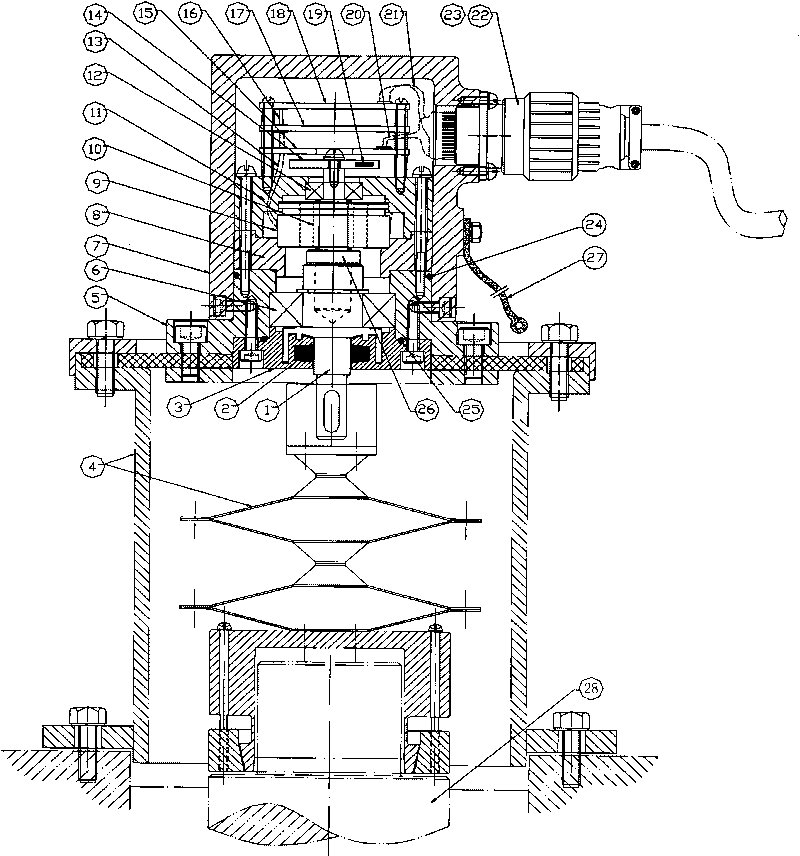

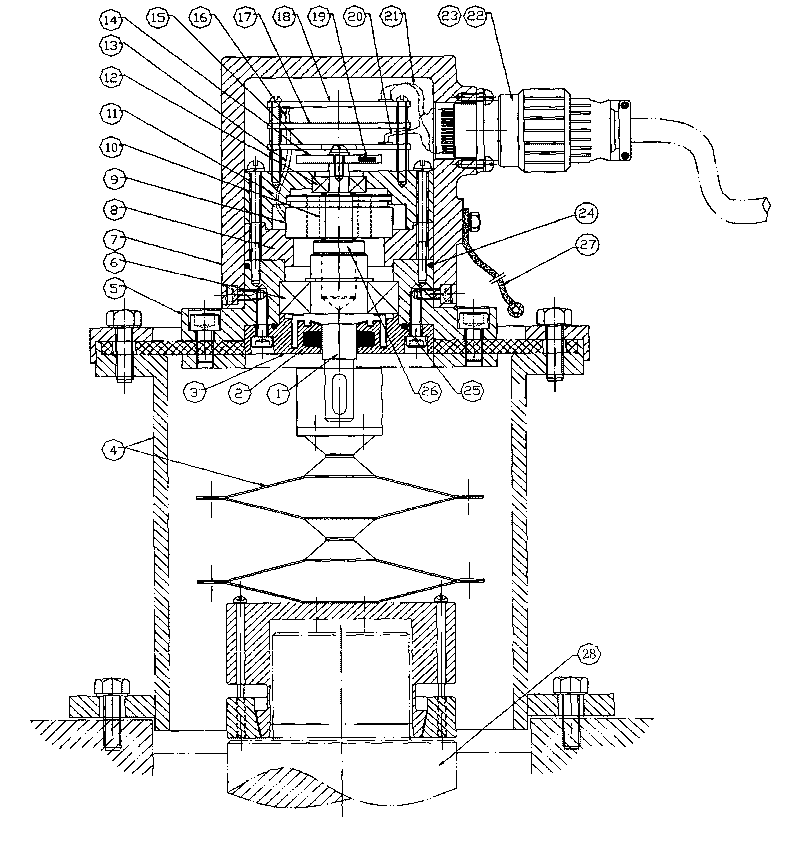

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0037] Please see attached figure 1 As shown, the heavy-duty absolute multi-turn rotary encoder provided by the present invention includes: input shaft 1; high-speed sealing ring 2; heavy-duty labyrinth bearing cap 3; heavy-duty bearing seat 5; heavy-duty bearing 6; heavy-duty housing 7. Resolver base 8; Resolver stator 9; Resolver rotor 10; Resolver bearing cover 11; Precision bearing 12; Resolver lead wire 13; Turn number sending disk 14; Multi-turn counter PCB board 15; RD connection line 16 ; RD intelligent decoder PCB board 17; data output PCB board 18; magnetic steel 19; multi-turn counter data output line 20; single-turn data output line 21; single-turn data output sealed aviation plug 22; Aviation plug 23; bearing seat O-ring 24; bearing cover O-ring 25; insulating shaft 26; ground braid 27.

[0038]The heavy-duty shell 7 is made of high-quality mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com