Micro-projection optical engine

An optical engine and micro-projection technology, applied in the field of projection display, can solve the problems of inability to meet the requirements of miniaturization, light weight, many optical components, and complex structure, and achieve the effect of simple structure, small size, and high utilization rate of light energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

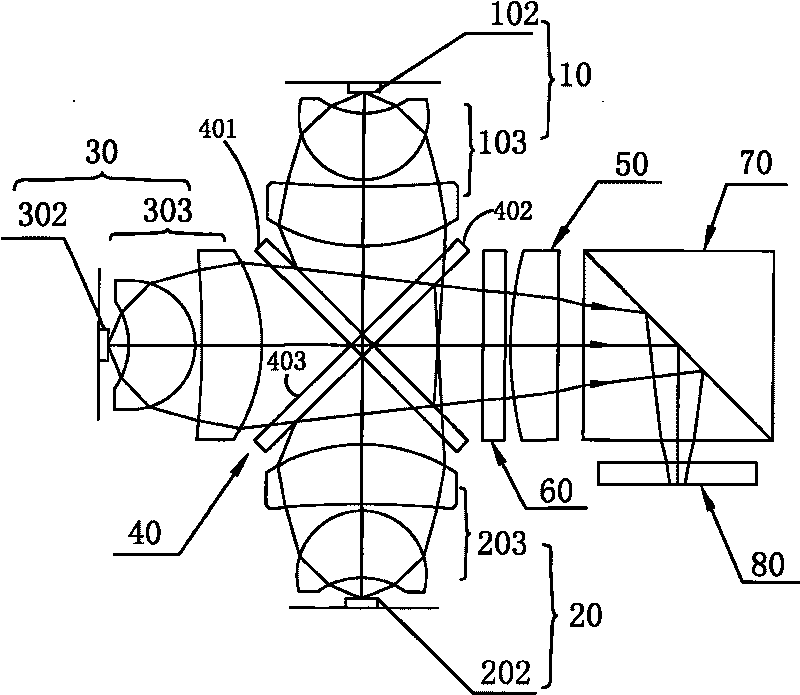

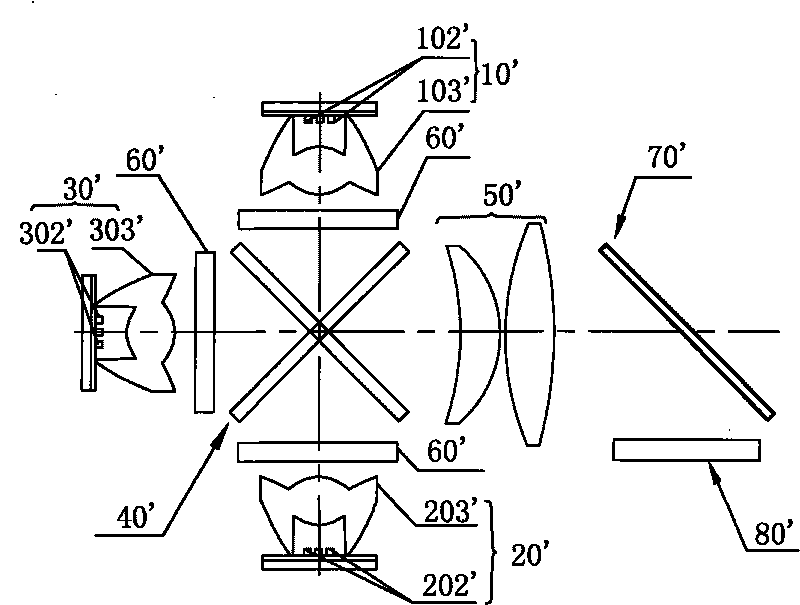

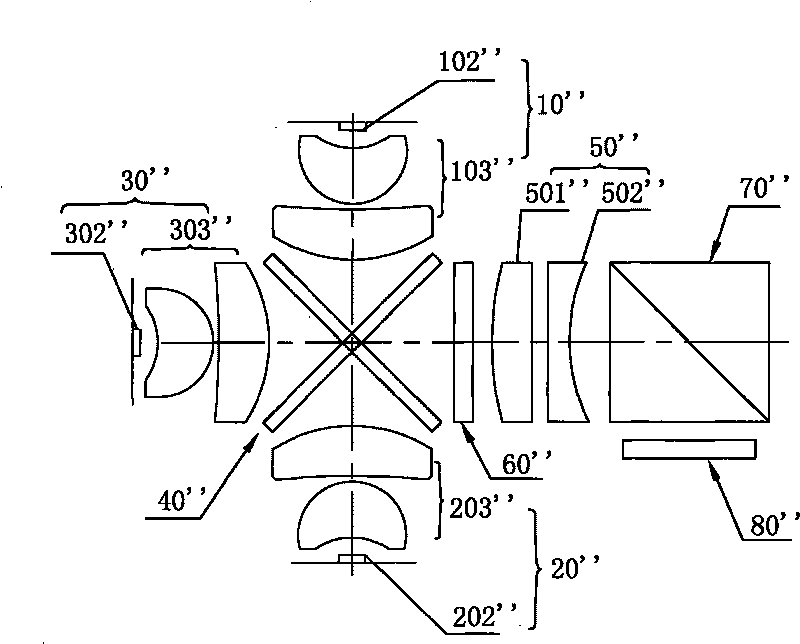

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0013] figure 1 Shown is a schematic plan view of the micro projection optical engine according to the first embodiment of the present invention, which includes a red light source module 10, a blue light source module 20, a green light source module 30, a cross-shaped dichroic mirror 40, and a lens group 50 , a polarization converter 60 , a polarization beam splitter 70 , a single microdisplay panel 80 and a projection lens (not shown in the figure). Among them, the red light source module 10 , the blue light source module 20 , the green light source module 30 , the cross-shaped dichroic mirror 40 , the lens group 50 and the polarization converter 60 constitute an illuminating device.

[0014] The red light source module 10 includes a red semiconductor light emitting element 102 and a first shaping lens group 103 for collecting and shaping the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com