Permanent magnet traction device with wider speed increasing range

A technology of traction motors and permanent magnets, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of small output torque, difficult production, and lack of industrialization, and achieve the rotor magnetic circuit structure Reasonable, raw material saving, reasonable arrangement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

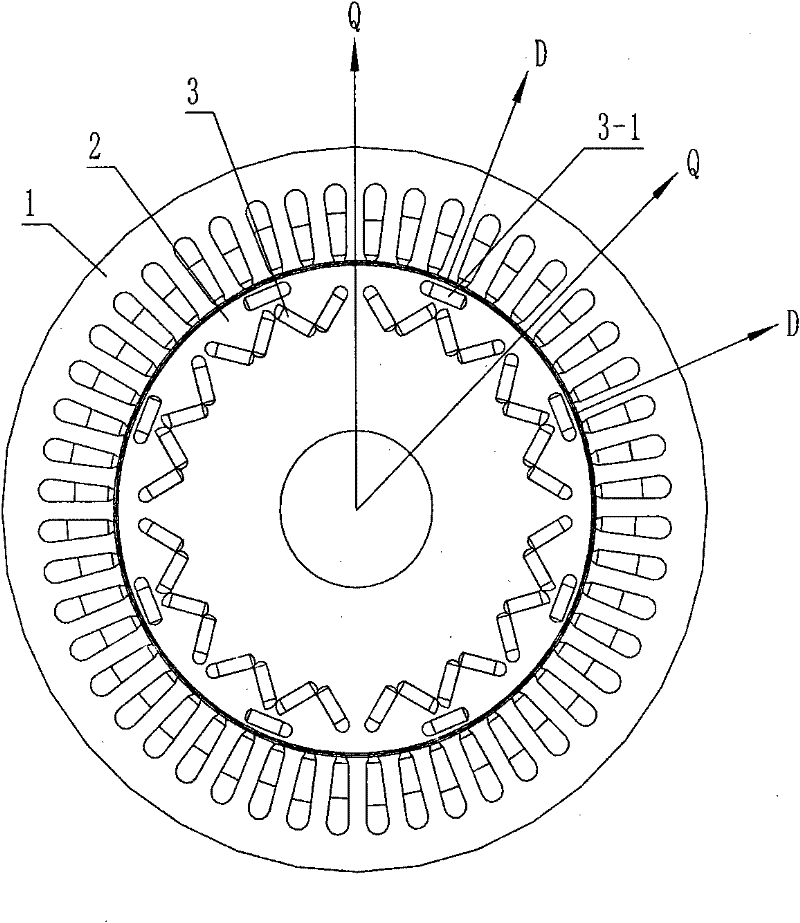

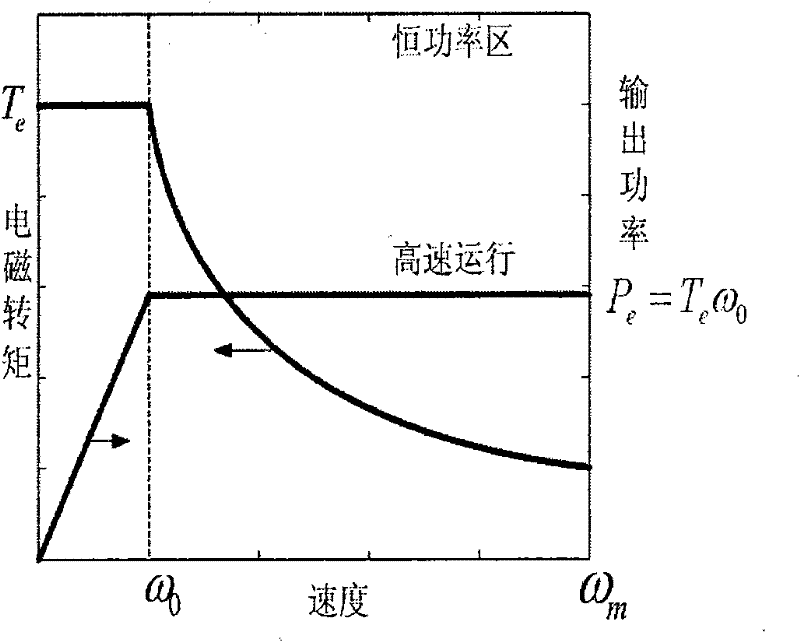

[0020] see figure 1 , figure 2 , this motor can be called W type, the permanent magnets in the rotor are arranged in a "W" shape, and an inline permanent magnet is placed horizontally on it, the purpose is to expand the constant power speed range and reduce the value of the d-axis inductance Ld. The saliency ratio increases, thereby increasing the constant power speed range.

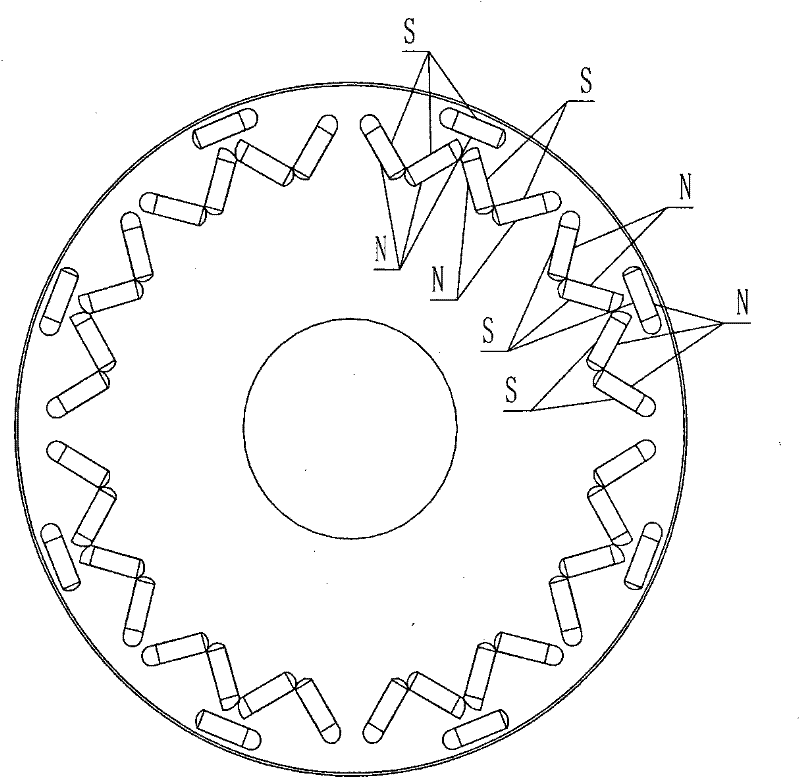

[0021] see figure 2 , the two permanent magnets in the direction of the d-axis have a small gap, and the gap between the two permanent magnets in the direction of the q-axis is slightly wider. This motor has a total of 8 poles, that is, 4 pairs of poles. So 1 / 4 is symmetrical, and it adopts the "micro-bias" theory: the gap between the permanent magnets of the two adjacent Q axes is slightly asymmetrical, which can reduce the pulsating torque output by the motor, and can be used at rated current. Ripple torque is reduced by 8.5%. At the same time, it should be noted that the symmetrical W type wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com