Method for manufacturing temporary heart pacing electrode catheter

An electrode catheter and cardiac pacing technology, applied in the direction of cardiac stimulators, etc., can solve the problems of increasing the workload of medical staff, expensive, difficult to obtain, etc., and achieve the effects of reducing medical burden, wide application range, and easy popularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

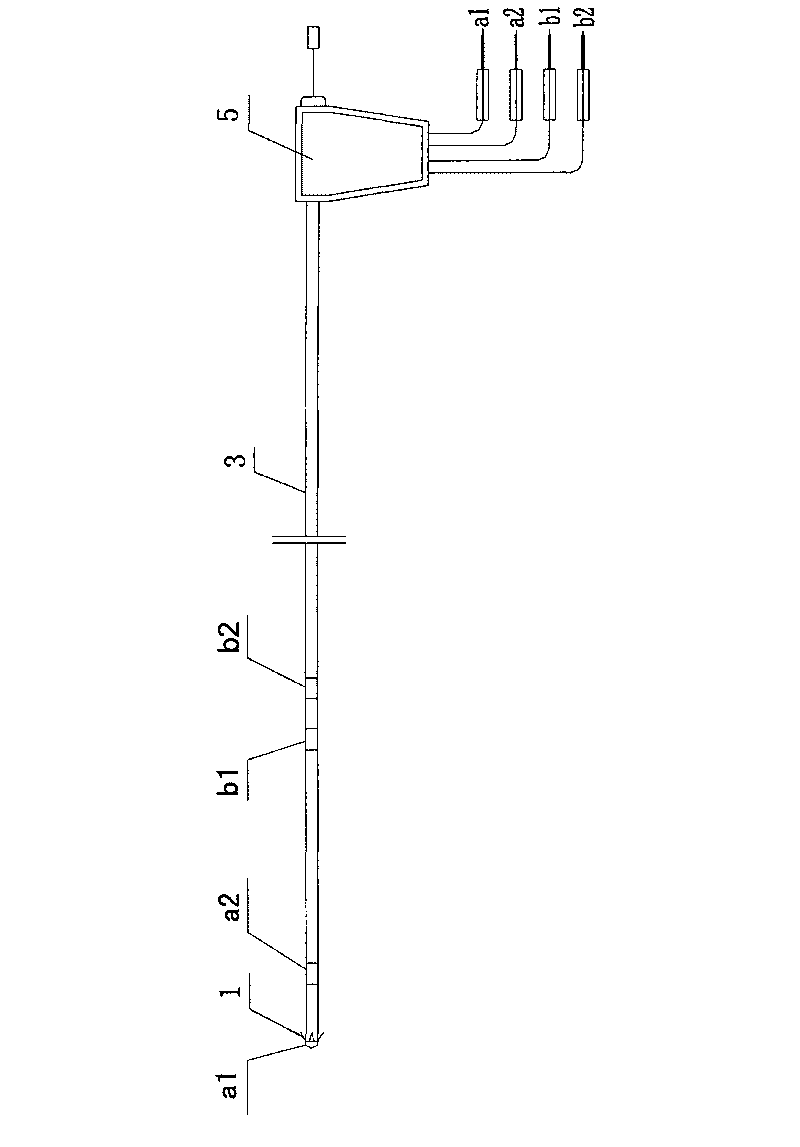

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

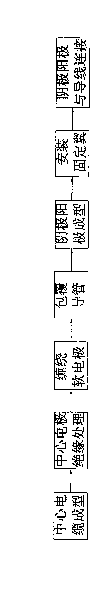

[0020] see Figure 1-Figure 3 , the manufacture method of temporary cardiac pacing electrode catheter, comprises the following steps:

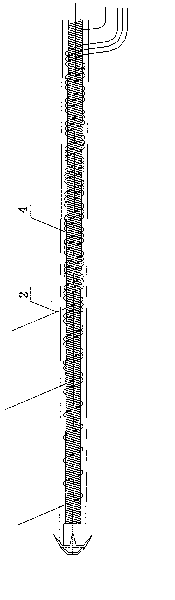

[0021] The center electrode 4 is formed, and a plurality of steel wires are closely wound side by side, so that the wound steel wires have a spring shape with axial stiffness and certain flexibility. The inner diameter of the wound center electrode 4 is 0.5mm, and a guide wire with a diameter of 0.4mm can be inserted in the middle. The multiple steel wires should be arranged tightly without gaps, and the guide wire inserted through the electrode will not pass through the side wall when the electrode is bent. .

[0022] Center electrode insulation treatment, covering the outer surface of the wound center ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com