Binding band type folding filter element

A folded filter element and strapping technology, which is applied to fixed filter elements, filter separation, and dispersed particle filtration, can solve the problems of complex processing and assembly of folded filter elements, easy blockage of the filter layer, heavy volume of the filter element, etc., and reduce the burden of filtration , low filtration cost, simple assembly and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

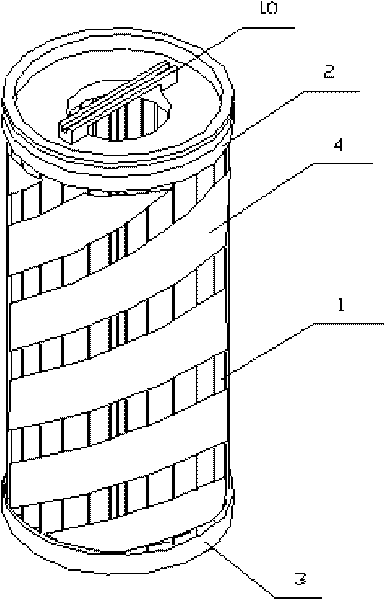

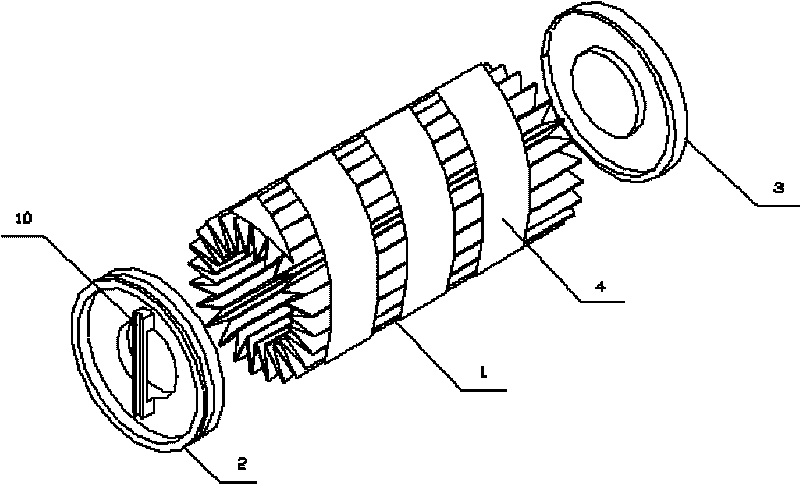

[0023] Embodiment 1: The strap-type pleated filter element of this embodiment, such as Figure 1 to Figure 4As shown, it includes a cylindrical pleated filter element body 1, an upper cover 2 placed on the upper end of the pleated filter element body 1 and bonded with the upper end of the pleated filter element body 1, and an upper cover 2 placed on the lower end of the pleated filter element body 1 and adhered to the lower end of the pleated filter element body 1 Connected to the lower cover 3, the cylindrical outer surface of the folded filter element body 1 is designed with multiple loops of soft and porous straps 4, the straps 4 are tightly fastened on the folded filter element body 1, and the folded filter element body 1 is in a divergent and multi-pleated shape. The multiple pleats are evenly distributed on the same circumference, and the pleat heights of the pleats are all equal. The filter layer between the valleys forms the filter surface of the pleated filter element...

Embodiment 2

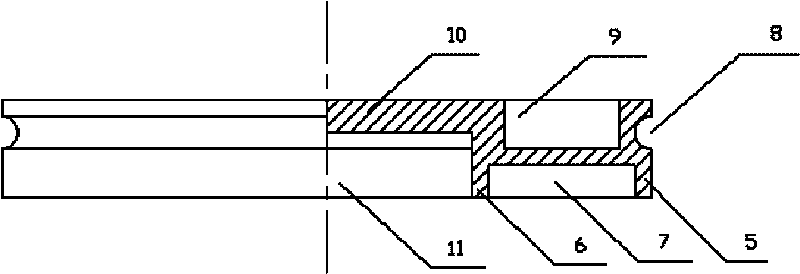

[0024] Embodiment 2: The strap-type pleated filter element of this embodiment, such as Figure 5 As shown, it includes a cylindrical pleated filter element body 1, an upper cover 2 placed on the upper end of the pleated filter element body 1 and bonded with the upper end of the pleated filter element body 1, and an upper cover 2 placed on the lower end of the pleated filter element body 1 and adhered to the lower end of the pleated filter element body 1 Connected to the lower cover 3, the cylindrical outer surface of the folded filter element body 1 is designed with a plurality of loops of independent soft porous straps 4, the straps 4 are annular and match the outer diameter of the folded filter element body 1, The width of the strap 4 is 20mm, the annular plane of each loop of the strap 4 is perpendicular to the axis of the folded filter element body 1, the strap 4 is tightly fastened on the cylindrical outer surface of the folded filter element body 1, and the tie between th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com