Completely degraded plant powder modified thermoplastics composite material and preparation method thereof

A wood-plastic composite material, completely degradable technology, applied in the field of wood-plastic composite material and its preparation, can solve the problems of difficult decomposition, environmental pollution, difficult degradation, etc., and achieves low cost, good dimensional stability, and easy molding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

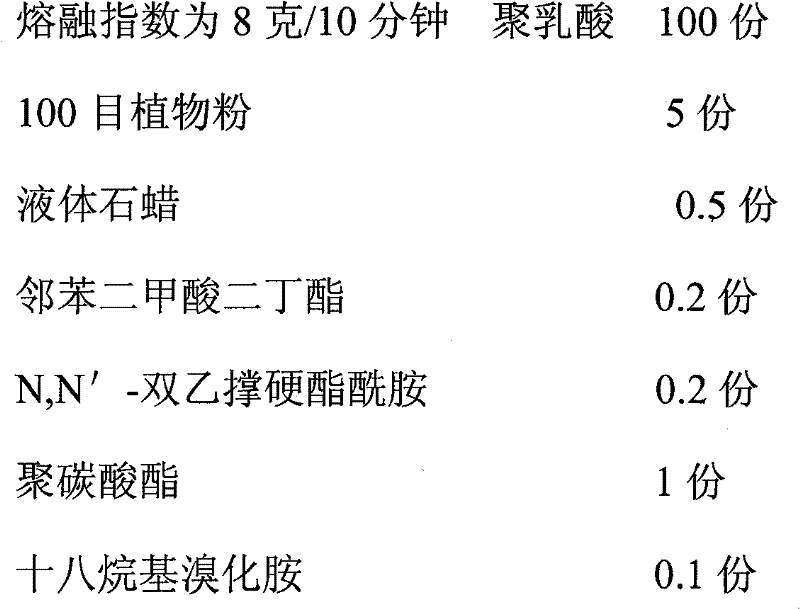

[0029] The raw material components are calculated in parts by weight:

[0030]

[0031] Plant powder needs to be dried in an oven at 120°C for 5 hours before use, and the moisture content should be controlled below 1%. First, the plant powder is treated with a dispersant in a high-speed mixer, and then other components are added to mix evenly. Add it into an extruder to extrude and granulate, and the processing temperature is controlled at 150°C to obtain a completely degraded plant powder modified thermoplastic wood-plastic composite material.

[0032] The tested properties of the above-mentioned wood-plastic composite materials are as follows:

[0033]

Embodiment 2

[0035] The raw material components are calculated in parts by weight:

[0036]

[0037]

[0038] Plant powder needs to be dried in an oven at 120°C for 6 hours before use, and the moisture content should be controlled below 1%. First, the plant powder is treated with a dispersant in a high-mixer, and then other components are added to mix evenly. Add it into an extruder to extrude and granulate, and the processing temperature is controlled at 190°C to obtain a completely degraded plant powder modified thermoplastic wood-plastic composite material.

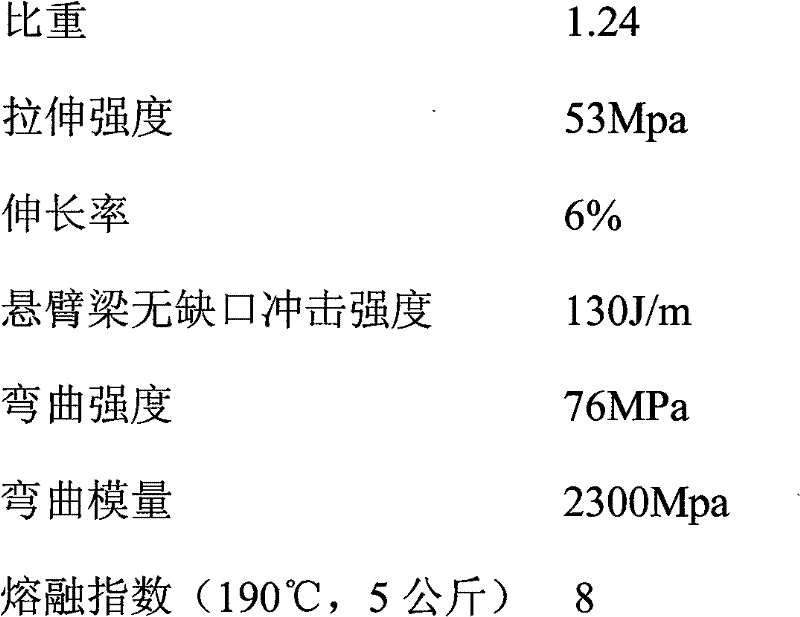

[0039] The tested properties of the above-mentioned wood-plastic composite materials are as follows:

[0040]

Embodiment 3

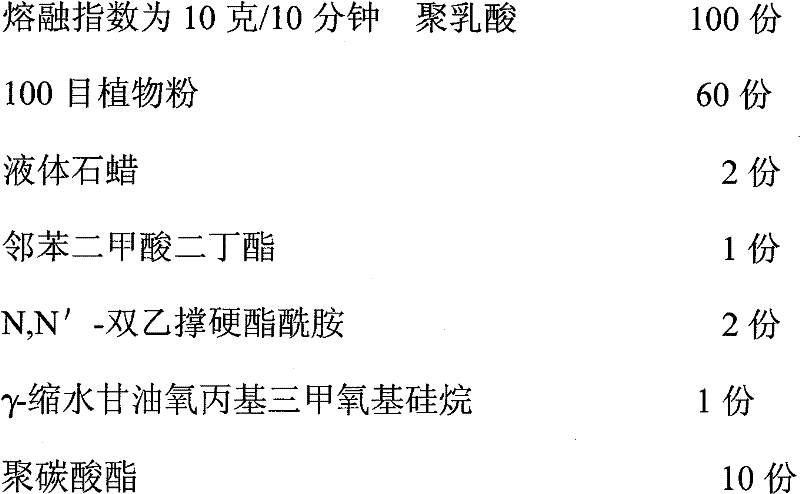

[0042] The raw material components are calculated in parts by weight:

[0043]

[0044]

[0045] Plant powder needs to be dried in an oven at 120°C for 7 hours before use, and the moisture content should be controlled below 1%. First, the plant powder is treated with a dispersant in a high-mixer, and then other components are added to mix evenly. Add it into an extruder to extrude and granulate, and the processing temperature is controlled at 170° C. to obtain a completely degraded plant powder modified thermoplastic wood-plastic composite material.

[0046] The tested properties of the above-mentioned wood-plastic composite materials are as follows:

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com