Flywheel simple harmonic motion four-stroke engine

A four-stroke engine and flywheel technology, which is applied in the direction of machines/engines, flywheels, mechanical equipment, etc., to achieve the effects of improving utilization, reducing processing costs, and reducing friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

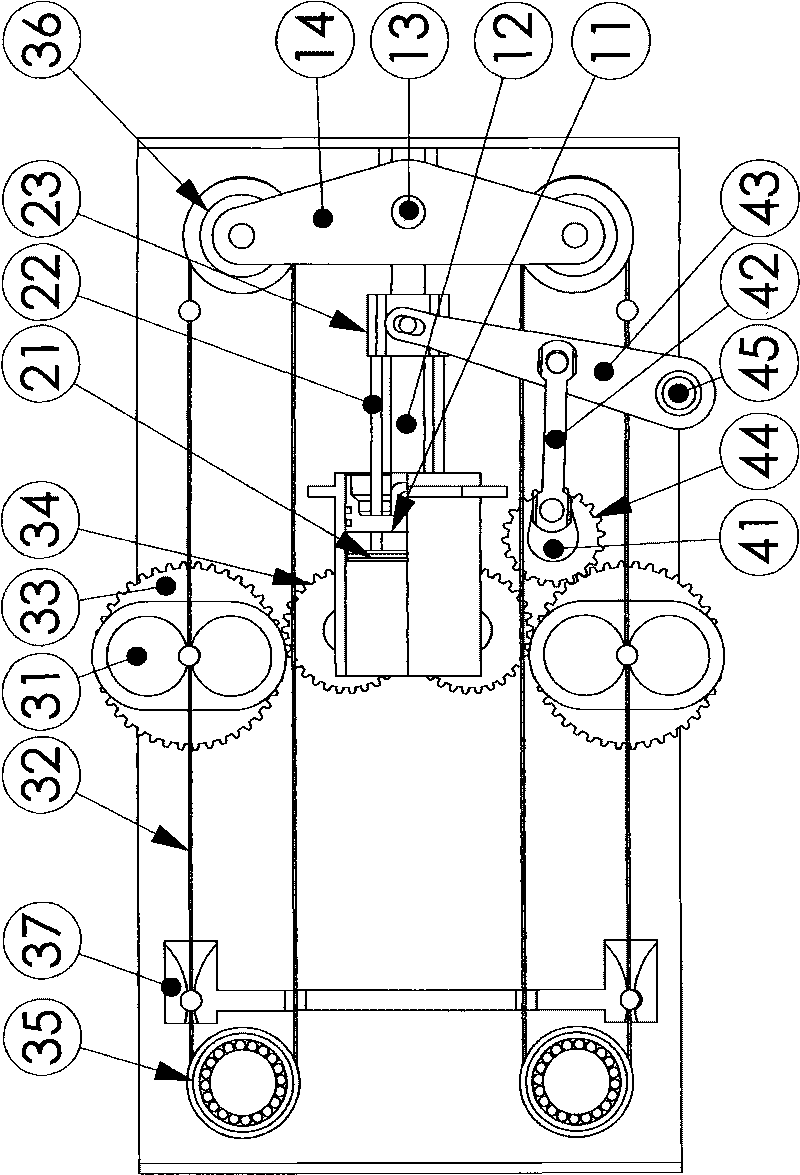

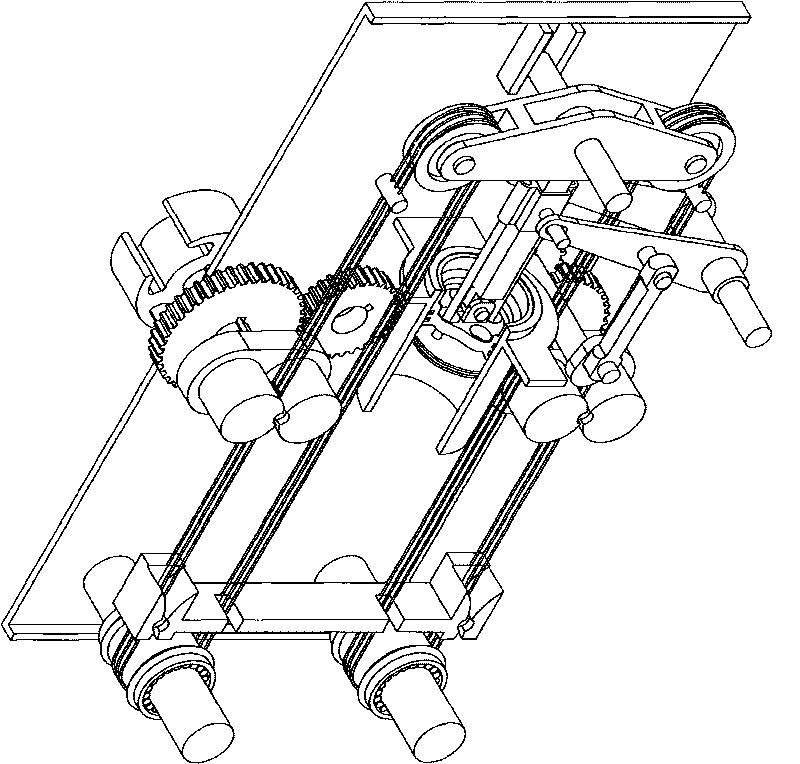

[0031] in the attached figure 1 In , the entire mechanism is roughly classified into the following types, and the composition and working principle of each mechanism are described as follows:

[0032] 1) Main piston mechanism.

[0033] Mechanism is composed of: main piston (11), piston rod (12), articulated shaft (13), scale beam (14).

[0034] Connection relationship: the main piston (11) and the piston rod (12) are hinged or joint socket connected, the piston rod (12) is hinged through the hinge shaft (13) and the beam (14), and the two ends of the hinge shaft (13) are embedded on the casing in the chute. The top of the main piston (11) has an air vent.

[0035] Working principle: the articulated shaft (13) is constrained by the chute to keep linear motion, and the piston rod (12) also keeps linear motion without swinging. Because the scale beam (14) is hinged with the piston rod, the force applied to both ends of the scale beam (14) Can not form moment to add on the pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com