Backlight source, manufacture method thereof, liquid crystal display and liquid crystal television

A manufacturing method and backlight technology, which are applied in the manufacture of discharge tubes/lamps, ships or leading wires, and instruments, can solve the problems of difficult operation, many assembly processes, and unfavorable thinning, so as to reduce materials, Effect of cost reduction and simplification of assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

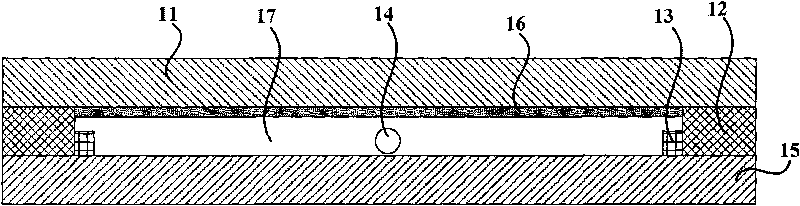

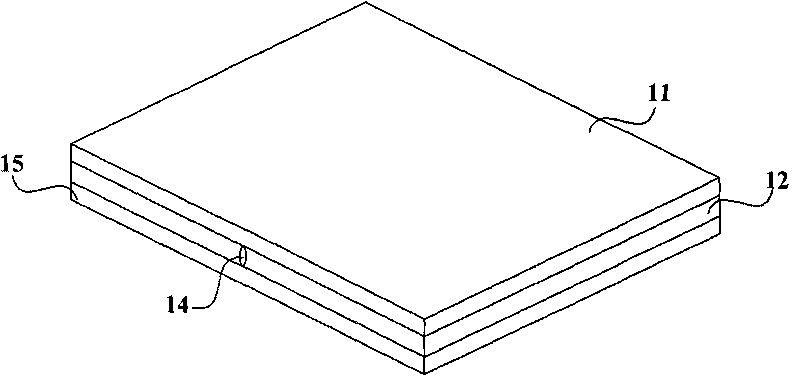

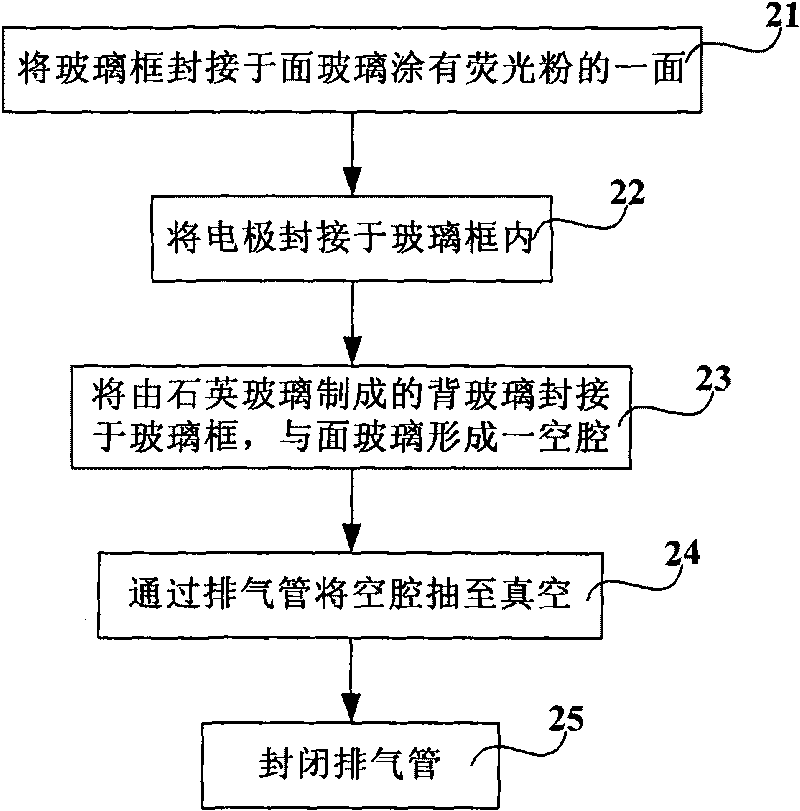

[0028] Figure 1A It is a schematic cross-sectional structure diagram of an embodiment of a backlight source of the present invention. Figure 1B for Figure 1A Schematic diagram of the three-dimensional structure. Such as Figure 1A , Figure 1B As shown, the backlight includes: a face glass 11, a glass frame 12, an electrode 13, an exhaust pipe 14 and a back glass 15. The face glass 11 is coated with phosphor 16; the glass frame 12 is sealed to the side of the face glass 11 coated with phosphor 16; the electrode 13 is sealed in the glass frame 12; the exhaust pipe 14 is sealed to the glass frame 12; the back glass 15 is made of quartz glass, sealed on the glass frame 12, and forms a cavity 17 with the face glass 11; the exhaust pipe 14 is in a closed state when the cavity 17 becomes vacuum.

[0029] In this embodiment, the backlight is formed by the face glass, the back glass and the flat glass cavity coated with phosphor powder in the glass frame, which can emit a uniform white l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com