Method for synthesizing novel visible light driven BI2WO6 photocatalyst by employing microemulsion-hydrothermal technology

A photocatalyst, visible light technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., to achieve the effects of no high temperature heat treatment, cost reduction, and simple and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

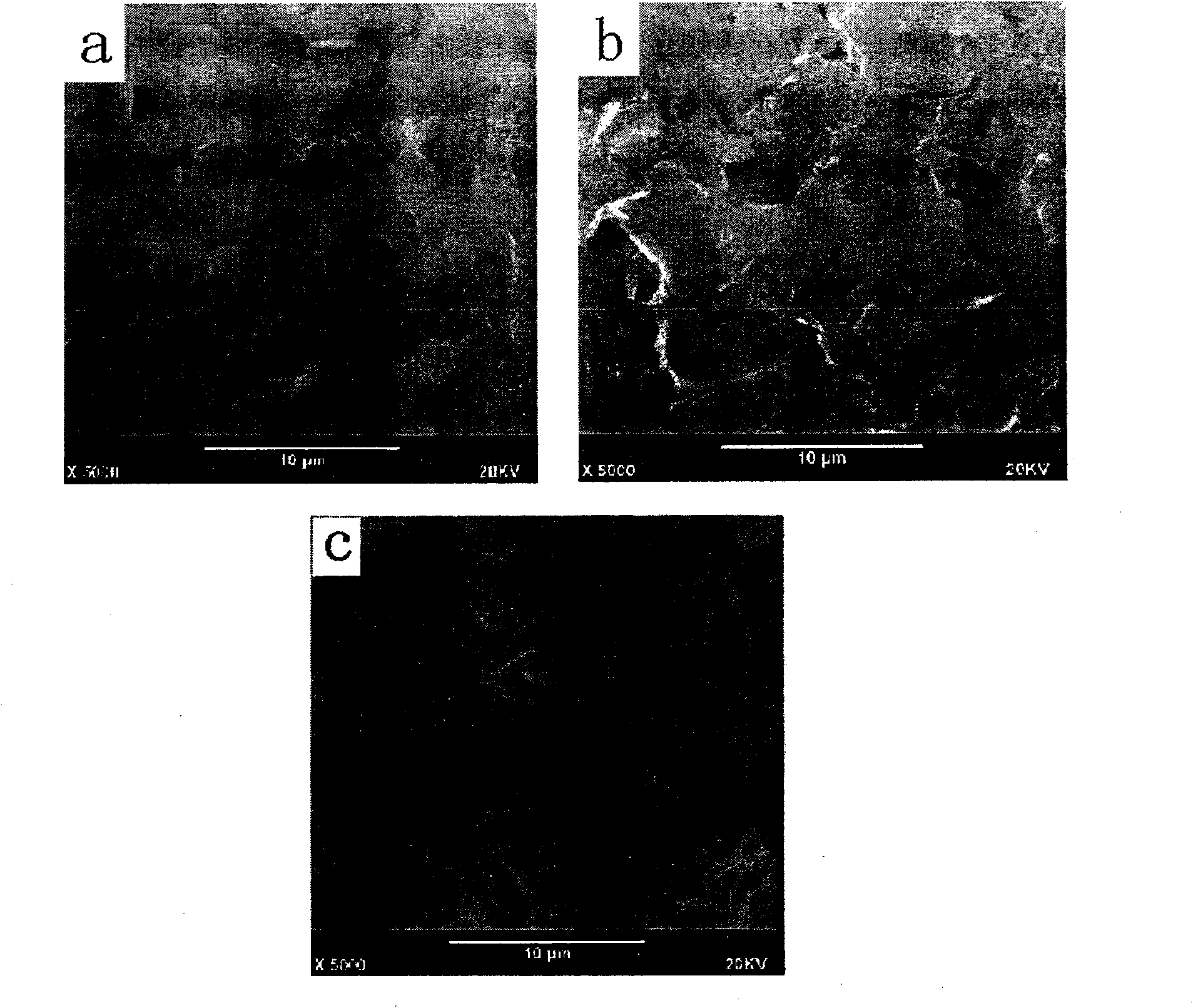

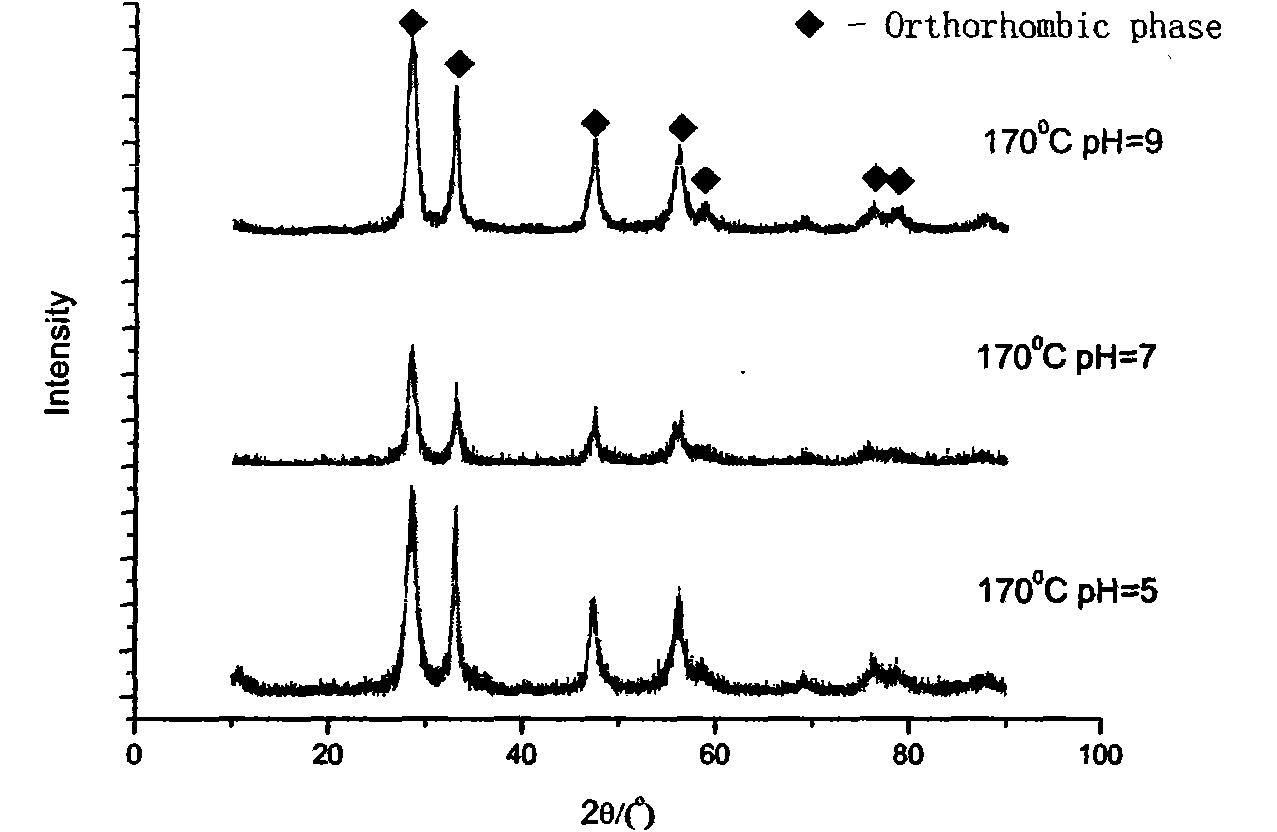

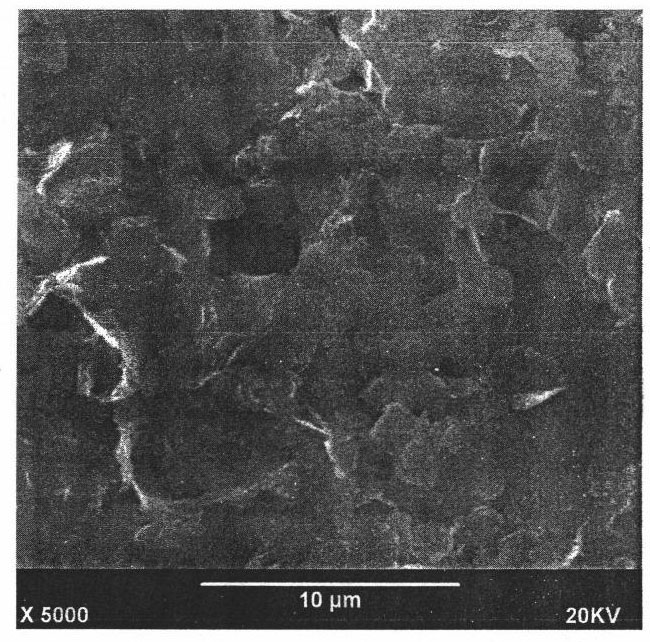

Embodiment 1

[0017] Weigh Tween 80: n-butanol: n-heptane in a certain ratio, and stir evenly on a constant temperature magnetic stirrer until the three are evenly mixed. Prepare two parts of such microemulsion systems in this way for future use. Weigh a certain amount of Na according to the stoichiometric ratio 2 WO 4 2H 2 O and Bi(NO 3 ) 3 ·5H 2 O, were dissolved in deionized water to make a transparent solution. The above two transparent solutions were respectively added into the above microemulsion system under the condition of constant stirring. Stirring was continued for 30 min to form a stable microemulsion system. Under vigorous stirring, the above two microemulsion systems were mixed together, and ammonia water (NH 3 ·H 2 O) Adjust the pH to about 7, and then continue to stir for 40 minutes to 60 minutes. Then put the above-prepared microemulsion system into a closed reaction kettle made of stainless steel and lined with white polytetrafluoroethylene for heat treatment at...

Embodiment 2

[0019] Weigh Tween 80: n-butanol: n-heptane in a certain ratio, and stir evenly on a constant temperature magnetic stirrer until the three are evenly mixed. Prepare two parts of such microemulsion systems in this way for subsequent use. Weigh a certain amount of Na according to the stoichiometric ratio 2 WO 4 2H 2 O and Bi(NO 3 ) 3 ·5H 2 O, were dissolved in deionized water to make a transparent solution. The above two transparent solutions were respectively added into the above microemulsion system under the condition of constant stirring. Stirring was continued for 30 min to form a stable microemulsion system. Under vigorous stirring, the above two microemulsion systems were mixed together, and ammonia water (NH 3 ·H 2 O) Adjust the pH to about 7, and then continue to stir for 40 minutes to 60 minutes. Then put the above-prepared microemulsion system into a closed reaction kettle made of stainless steel and lined with white polytetrafluoroethylene for heat treatmen...

Embodiment 3

[0021] Weigh Tween 80: n-butanol: n-heptane in a certain ratio, and stir evenly on a constant temperature magnetic stirrer until the three are evenly mixed. Prepare two parts of such microemulsion systems in this way for subsequent use. Weigh a certain amount of Na according to the stoichiometric ratio 2 WO 4 2H 2 O and Bi(NO 3 ) 3 ·5H 2 O, were dissolved in deionized water to make a transparent solution. The above two transparent solutions were respectively added into the above microemulsion system under the condition of constant stirring. Stirring was continued for 30 min to form a stable microemulsion system. Under vigorous stirring, the above two microemulsion systems were mixed together, and ammonia water (NH 3 ·H 2 O) Adjust the pH to about 7, and then continue to stir for 40 minutes to 60 minutes. Then put the above-prepared microemulsion system into a closed reaction kettle made of stainless steel and lined with white polytetrafluoroethylene for heat treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com