Method for synthesizing novel Ca-Bi-O visible light catalyst by adopting soft chemistry-hydrothermal technology

A photocatalyst, ca-bi-o technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. High visible light catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

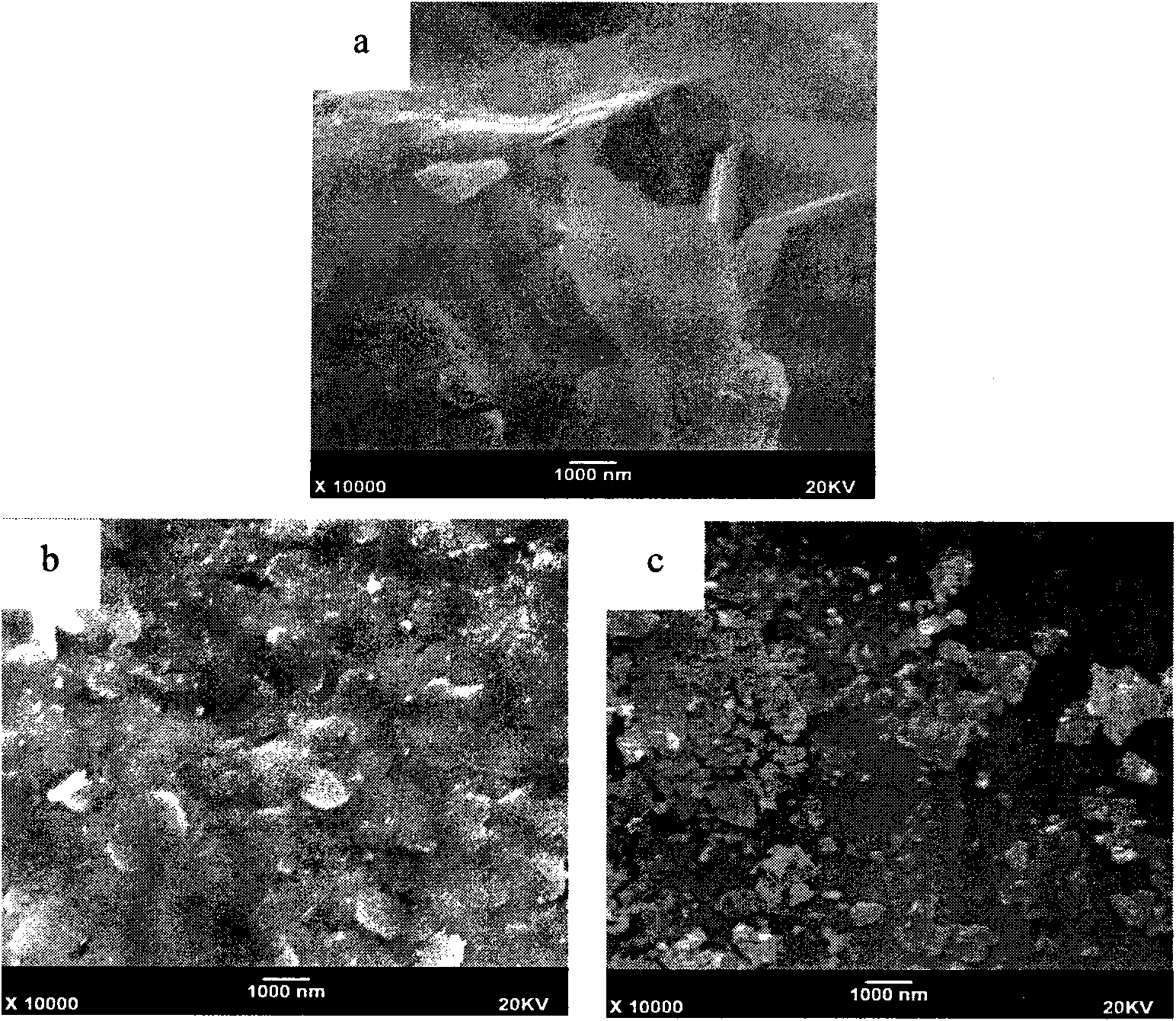

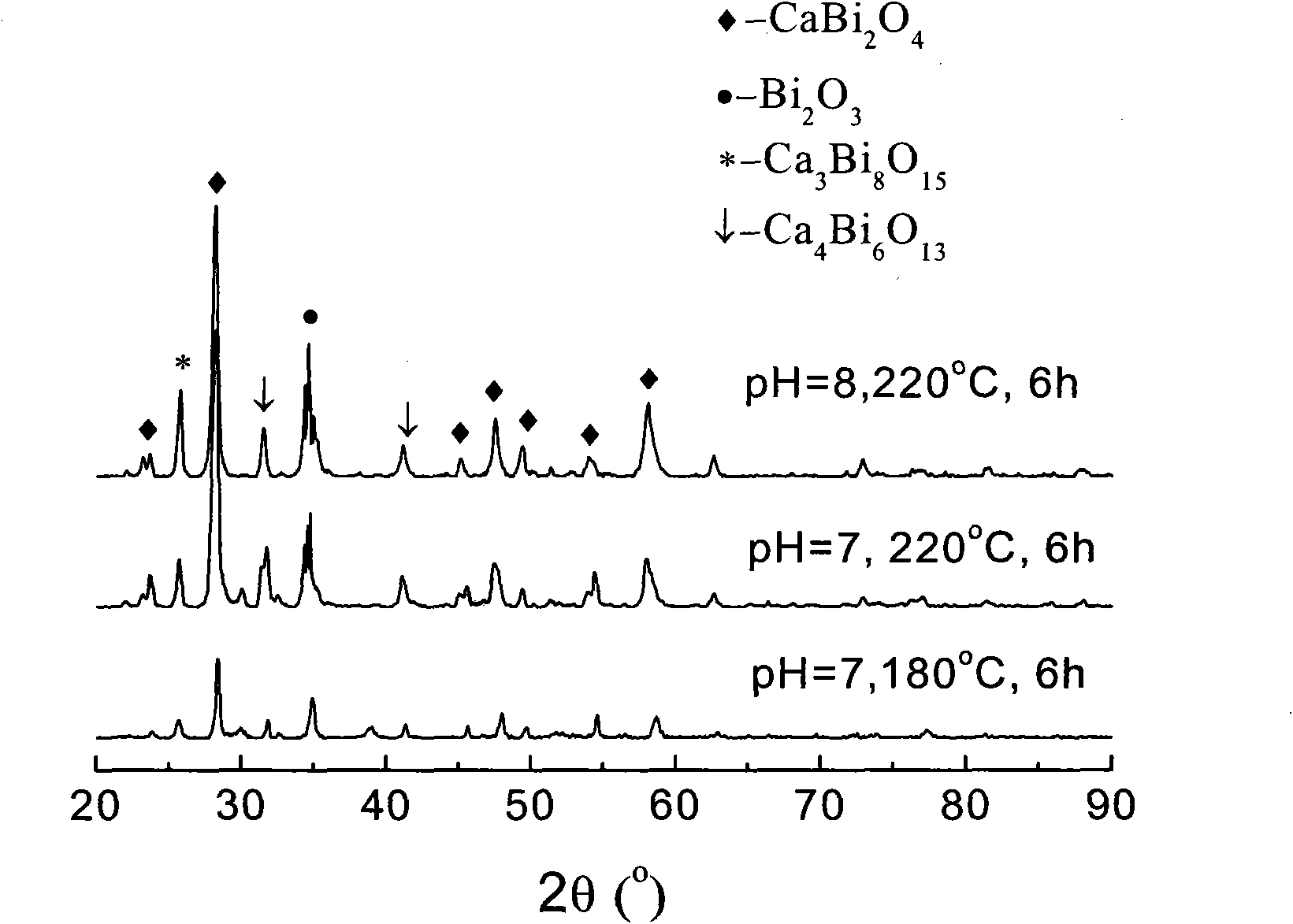

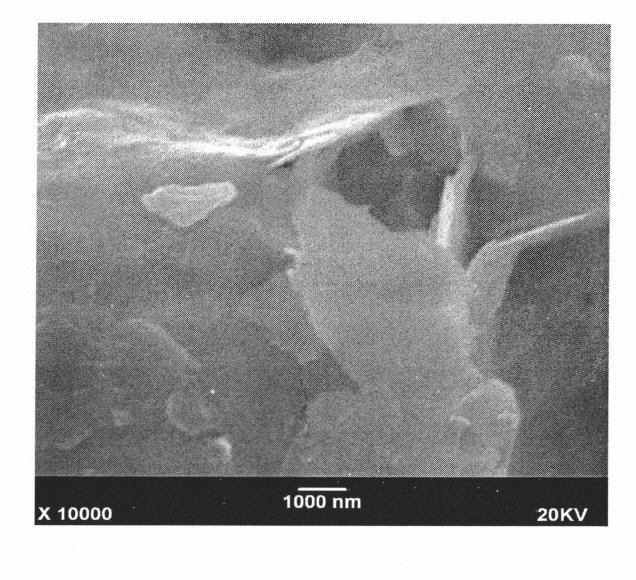

Embodiment 1

[0015] Weigh a certain amount of Ca(NO 3 ) 2 4H 2 O and Bi(NO 3 ) 3 ·5H 2 O, Ca(NO 3 ) 2 4H 2 O was dissolved in 50ml deionized water to make a transparent solution, and then Bi(NO 3 ) 3 ·5H 2 O was dissolved in 50ml of dilute nitric acid solution just prepared, put the above two transparent solutions into a 200ml beaker and mix, and stirred for 30min to make it evenly mixed. Take a 500ml beaker, add 100ml deionized water as the bottom solution, mix the solution with 3mol / L ammonia water (NH 3 ·H 2 O) The two solutions are titrated together in the bottom solution, while stirring continuously to mix the precipitation reactants evenly, so that the pH of the reaction solution is kept at about 6, and the precipitation suspension obtained after the titration is completed is continued to stir and age for 30 minutes. Then use a centrifuge to separate the solid from the liquid, and wash the resulting white precipitate with deionized water to remove NH 4 + and NO 3 - , ...

Embodiment 2

[0017] Weigh a certain amount of Ca(NO 3 ) 2 4H 2 O and Bi(NO 3 ) 3 ·5H 2 O, Ca(NO 3 ) 2 4H 2 O was dissolved in 50ml deionized water to make a transparent solution, and then Bi(NO 3 ) 3 ·5H 2 O was dissolved in 50ml of dilute nitric acid solution just prepared, put the above two transparent solutions into a 200ml beaker and mix, and stirred for 30min to make it evenly mixed. Take a 500ml beaker, add 100ml deionized water as the bottom solution, mix the solution with 3mol / L ammonia water (NH 3 ·H 2 O) The two solutions are titrated together in the bottom solution, while stirring continuously to mix the precipitation reactants evenly, so that the pH of the reaction solution is kept at about 7, and the precipitation suspension obtained after the titration is completed is continued to stir and age for 30 minutes. Then use a centrifuge to separate the solid from the liquid, and wash the resulting white precipitate with deionized water to remove NH 4 + and NO 3 - , ...

Embodiment 3

[0019] Weigh a certain amount of Ca(NO 3 ) 2 4H 2 O and Bi(NO 3 ) 3 ·5H 2 O, Ca(NO 3 ) 2 4H 2 O was dissolved in 50ml deionized water to make a transparent solution, and then Bi(NO 3 ) 3 ·5H 2 O was dissolved in 50ml of dilute nitric acid solution just prepared, put the above two transparent solutions into a 200ml beaker and mix, and stirred for 30min to make it evenly mixed. Take a 500ml beaker, add 100ml deionized water as the bottom solution, mix the solution with 3mol / L ammonia water (NH 3 ·H 2 O) The two solutions are titrated together in the bottom solution, while stirring continuously to mix the precipitation reactants evenly, so that the pH of the reaction solution is kept at about 7, and the precipitation suspension obtained after the titration is completed is continued to stir and age for 30 minutes. Then use a centrifuge to separate the solid from the liquid, and wash the resulting white precipitate with deionized water to remove NH 4 + and NO 3 - , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com