Processing technology of colored glaze product by glass

A processing technology, glass glaze technology, applied in decorative art, special art surface treatment, decorative structure and other directions, can solve the problems of complex production process and low yield, and achieve the effects of simple operation, low rejection rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

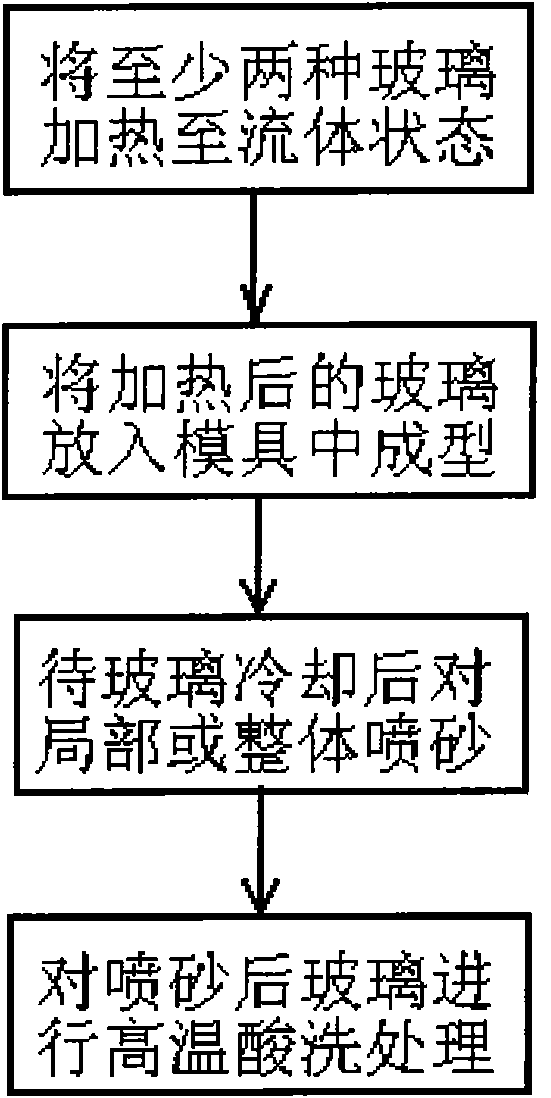

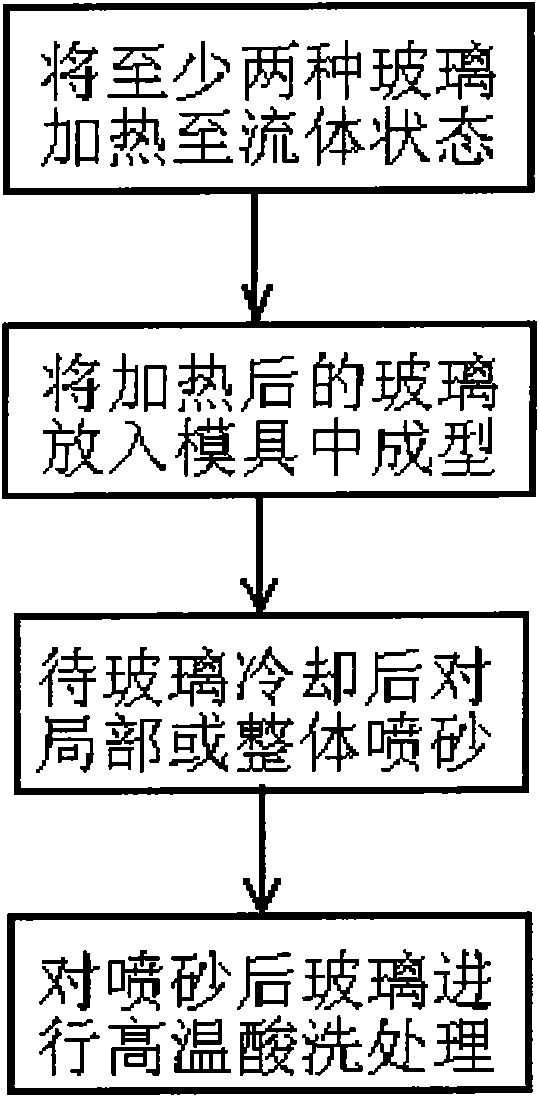

[0022] Such as figure 1 Shown, the specific embodiment of the present invention is:

[0023] A processing technology for producing glazed glass products, the technology includes the following steps:

[0024] Step 1: Heat at least two glasses of different colors to a semi-fluid state. According to the needs of product patterning, multiple glasses of different colors and varieties can be selected for heating at the same time;

[0025] Step 2: Put the glass of different colors that has been heated into a semi-fluid state into the corresponding part of the mold according to the shape and composition of the glass product, or directly press the glass of different colors that has been heated into a semi-fluid state Splicing (pressing), cutting, stretching, thermal carving, shape modification and other treatments;

[0026] Step 3: After the glass is cooled, perform sandblasting treatment on the part or the whole of the glass glazed product according to the needs of the product patte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com