Pressure control device for equalizing reservoir of motor vehicle

A technology of balancing air cylinders and pressure control, applied in the direction of brake transmission, brakes, vehicle components, etc., can solve the problems of low pressure control accuracy, can not fully meet the control requirements, etc., to improve reliability, improve locomotive safety, The effect of improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

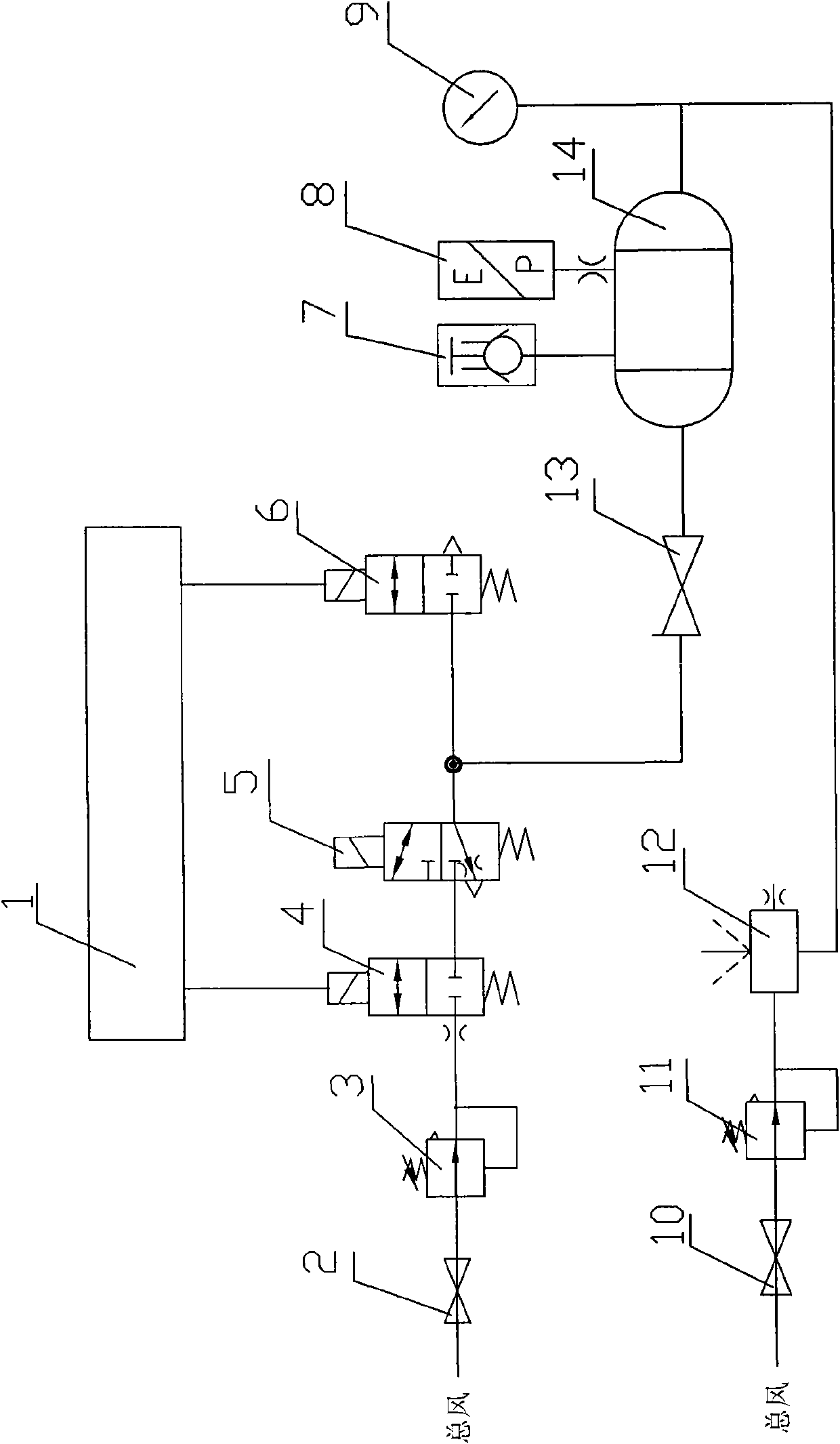

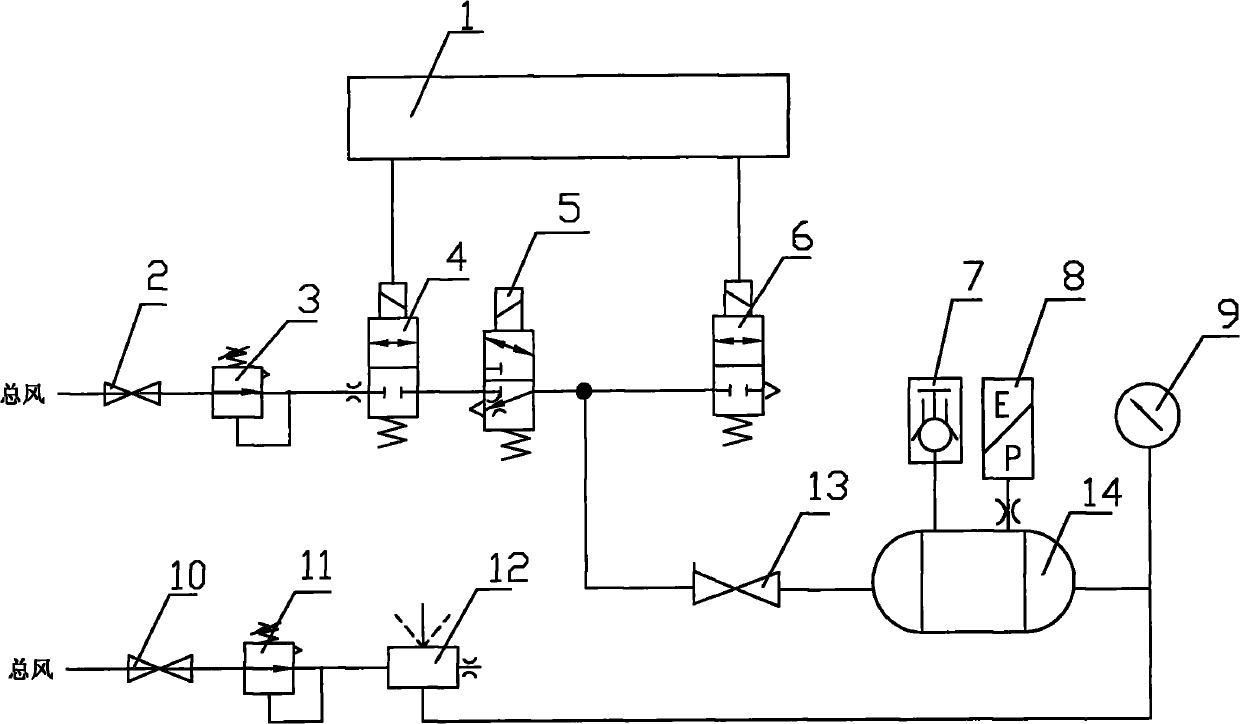

[0024] Such as figure 1 As shown, this embodiment provides a pressure control module for a locomotive equalizing air cylinder, which includes a proportional controller 1 that sends a PWM signal, two bus control plugs 2 and a bus control plug that control the intake and cut-off of the total air Door 10, two pressure regulating valves 3 and 11 for adjusting the total air pressure, intake high-speed electro-pneumatic valve 4, exhaust high-speed electro-pneumatic valve 6, protection electro-pneumatic valve 5, pressure sensor 8, switching valve 13, backup brake Valve 12, balanced air cylinder 14, balanced air cylinder pressure detection port 7 and balanced air cylinder pressure gauge 9, etc.

[0025] Among them, the proportional controller 1, the total air control plug 2 that controls the total air intake and cut-off, the two pressure reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com