High-speed and energy-saving train

A train and high-speed technology, applied in the field of high-speed energy-saving trains, can solve the problems of limited effect and limited energy consumption of trains, and achieve the effect of avoiding the formation of large and small negative pressure areas, getting rid of cost consumption, and saving energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

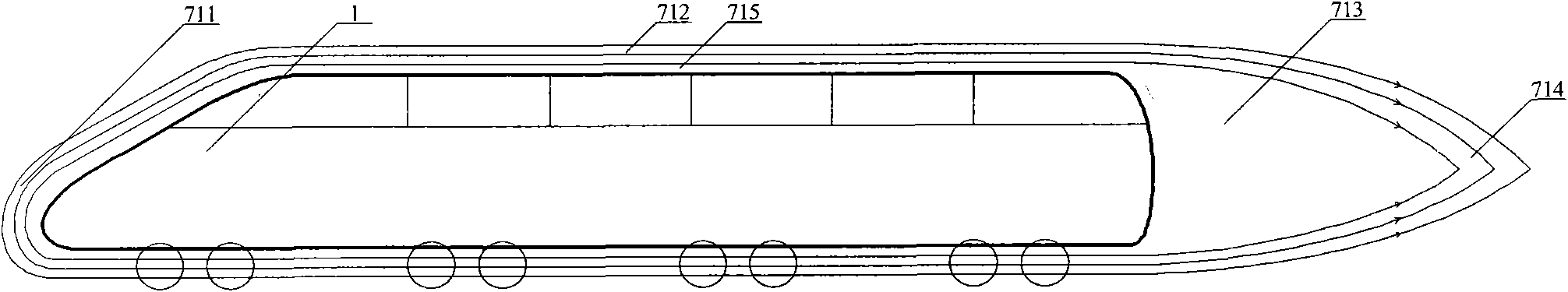

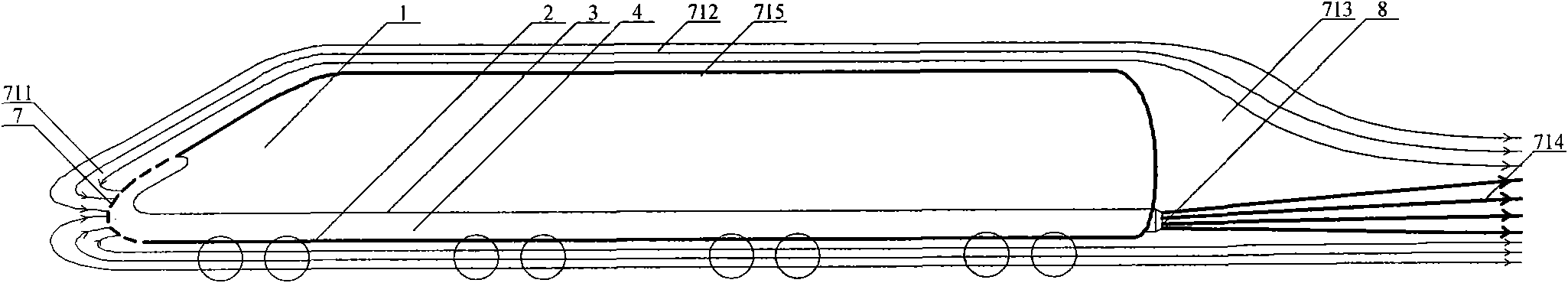

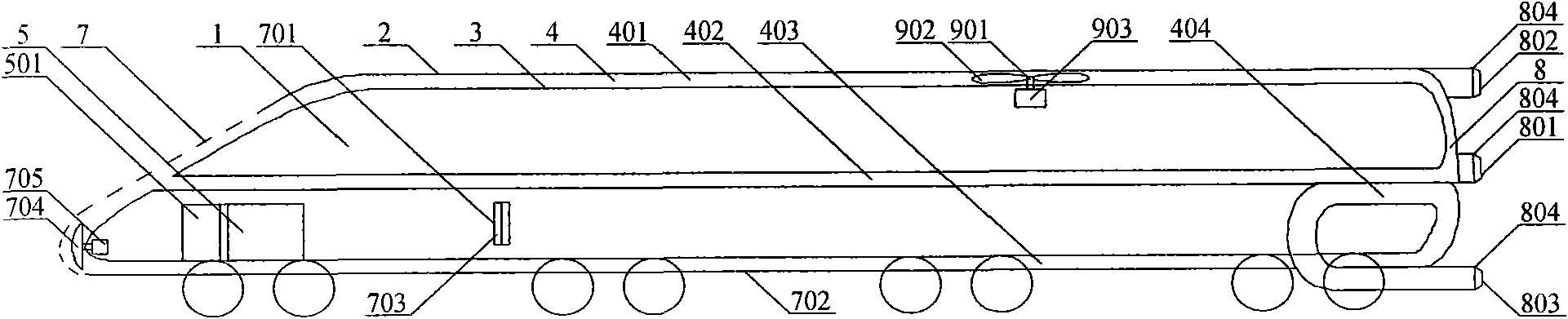

[0047] Such as image 3 , 4Shown is a specific embodiment of a double-deck high-speed energy-saving train, which includes a train body 1, the train body 1 is composed of an inner shell 3 and an outer shell 2, and a certain distance between the inner shell 2, 3 forms an annular fluid around the train The channel 4 is provided with a fluid inlet 7 at the front end of the shell 2, and the fluid inlet 7 is connected to the rear end outlet 8 through the fluid channel between the shells to form a top fluid channel 401, a top outlet 802, a middle fluid channel 402, and a middle guide port. The outlet 801 and the bottom fluid channel 403 , the annular hole 404 , and the bottom outlet 803 . A rotator 704 driven by a motor 705 is provided in the front fluid inlet 7, and the rotator 704 is used for rapid rotation to throw away the positive fluid resistance and avoid the resistance generated by the largest positive fluid directly colliding with the inner shell 3; The casing 2 around the...

Embodiment 2

[0054] Such as Figure 5 Shown, the high-speed train of the present embodiment is different from embodiment one: the shell 2 and the inner shell 3 of the fluid channel 4 at the bottom of each compartment of the train are spoiler surfaces 114 (as Figure 11 ), and the rear part is provided with a return-shaped export port 8, and at least one export port 801 is provided in the middle. Or the turbulence surface of concave-convex alternate streamlined surface, each turbulence surface is made of materials that can absorb the sun, and the absorbed solar energy is converted into electric energy and stored in the storage battery 907, and together with the storage battery 904 and compressed gas, an energy system is formed.

[0055] see Figure 6-7 , in the fluid channel 4 at the bottom of the train, it is divided into 3 independent or semi-independent guide chambers (if the channel plate 404 is not completely cut off, it is a half cutoff) by two concave-convex parabolic channel plates...

Embodiment 3

[0060] Such as Figure 8 As shown, the high-speed energy-saving train of the present embodiment is different from Embodiment 2 in that its power system adopts a turbofan engine 801 in the middle of the train main body 1 rear circular shell 201 to concentrate the main power on the main body 1 rear, and the electric A hybrid power system with motor and air motor auxiliary power. The bottom of the train main body shell 2 is provided with a spoiler surface 113 (see Figure 10 ), so that the fluid flow path in the bottom fluid channel and outside the channel (between the spoiler surface and the ground) is not less than the path passing through the upper part of the train, thereby eliminating lift resistance, and its rear end is provided with a circular shell 201, which is convenient for filling small The negative pressure zone can effectively reduce the area of the negative pressure zone, and is also conducive to the rapid passage of the fluid. At least one strip-shaped convex s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com