High-speed and energy-saving train

A train and high-speed technology, applied in the field of high-speed energy-saving trains, can solve problems such as limited effect, avoid the formation of large and small negative pressure areas, reduce the effect of fluid resistance, and get rid of cost consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

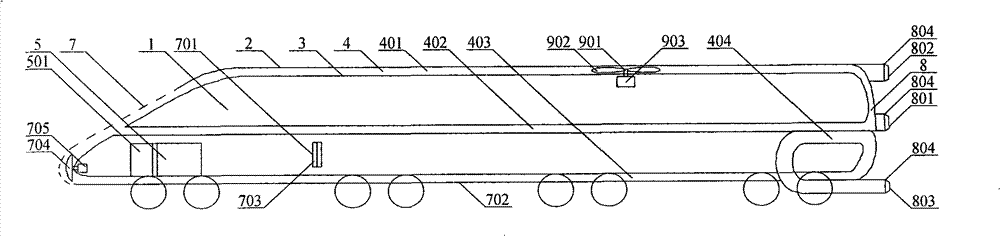

Embodiment 1

[0049] See Figure 4 It is proposed a diagram suitable for the power system for high -speed energy -saving trains for the present invention. The power system set in the train main body 1 consists of driving mechanism and gas storage equipment 5. The backup gas storage equipment isThe valve is connected to the driver through the catheter. The driver includes the pneumatic motor 603, and the pneumatic motor 603 corresponds to the driving wheel 6.Inside the fluid passage 4 of the train main 1, the wind tool 9 driven by wind power 9 to drive the impeller 902 and the axle 901, each ends can drive a air compressor 905 to supplement the compressed gas for the gas storage equipment 5 spare gas storage equipment.There are injection port 502, air pressure table 503, air pressure regulating valve 504, flow regulating valve 505, solenoid valve 506, and solenoid valve 506 connect the pneumatic motor 603 through a catheter 507, driving the reducer 602 rotation 605 rotation, and then drive 2The d...

Embodiment 2

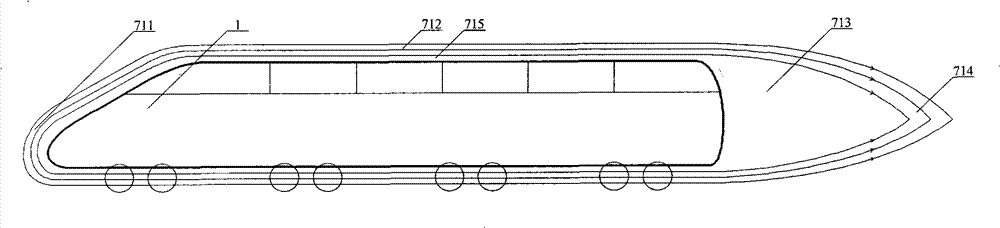

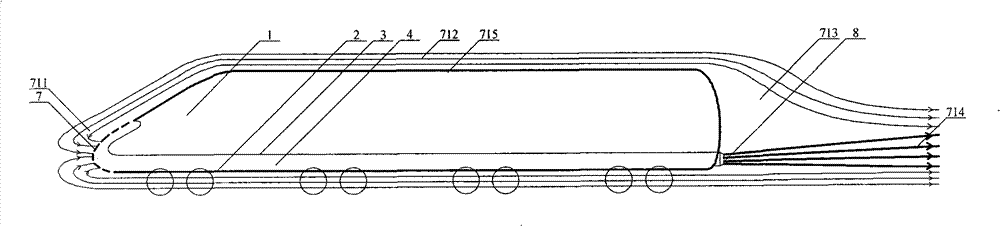

[0056]When high -speed trains are driving at high speed, the fluid wall is the maximum forward fluid resistance from the inhalation of the circular fluid channel from the import port 7, and at the same time of no less than one bar -shaped window guide entrance 701, fixed bar 706, 707 balanced guide entrance 702 handleThe fluid resistance of the fluid hole is inhaled into the fluid passage. When the fluid disturvisates the current surface through the shell, the resistance becomes less resistant at 113, 115, 116, and 114.Because there are 2 bumping channel board 404 within the bottom fluid passage 4, the divided flow cavity 401, 402, 403, and at least one spoiler 405 formed 3 bump parabolic planes are evenly distributed, so that the fluid absorbed from each inlet inlet is in the various absorbing inlets.The three guide cavity accelerates movement, so that the fluid flow velocity in the bottom fluid channel at the bottom is at least equal to the flow velocity in the upper fluid chann...

Embodiment 3

[0062] Example IV

[0063] like Figure 9 Different from Example 3 shows that in this embodiment, the body structure that does not use fluid imports and exports in this embodiment, but only sets the motor 705 through the main front end of the main body., The intersection of the cone 803, the intersection point is very small; Figure 10 ), Set the spoiler 117 on both sides (see Figure 14 ), When the entire high -speed energy -saving train is driving quickly, the rotating head 704 drives high -speed rotation under the motor 705, throw the fluid resistance of the largest fluid wall to the surroundings, and only use the rotation head 704 to be a little bit of power to put the front end of the train head at the front of the train.The fluid resistance is greatly reduced, and the fluid hole formed by the fluid wall is tightly wrapped in the train and then reached the intersection 803 at the same time along the housing shell of the rear cone 201. At this time, because the shape of the rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com