Test platform for ship propulsion system

A technology for propulsion power and test platform, which is applied in ship components, ship construction, ships, etc., and can solve the problems of lack of test verification methods, complex structure, large size and weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

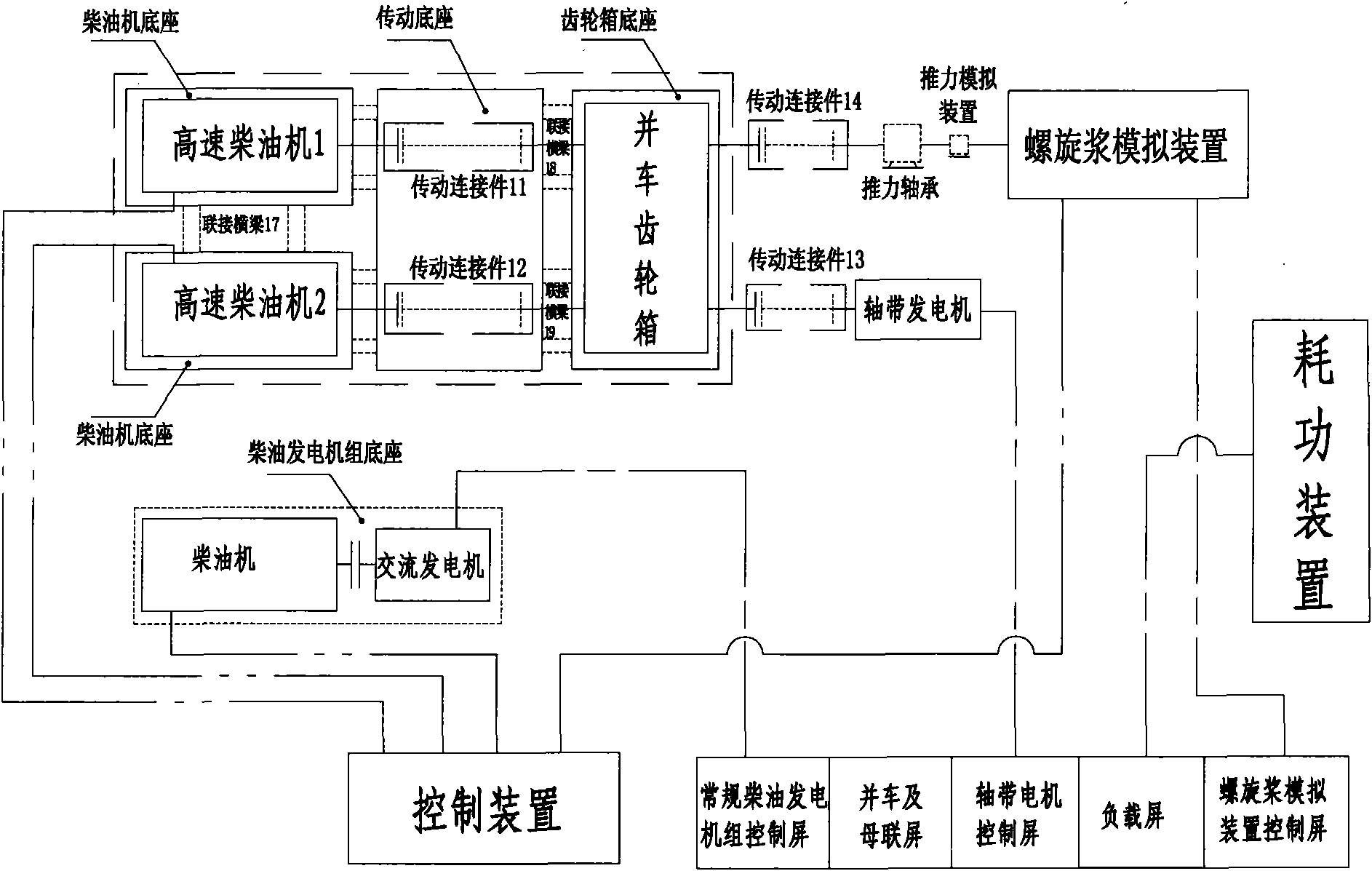

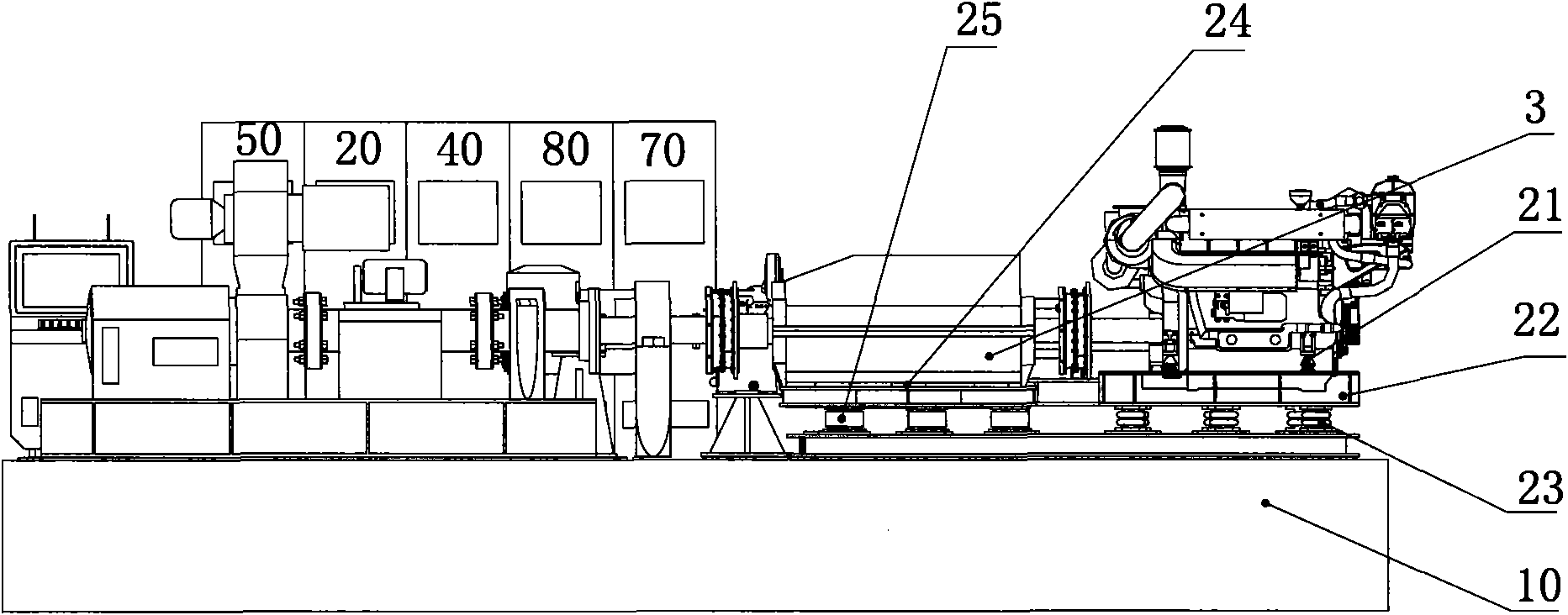

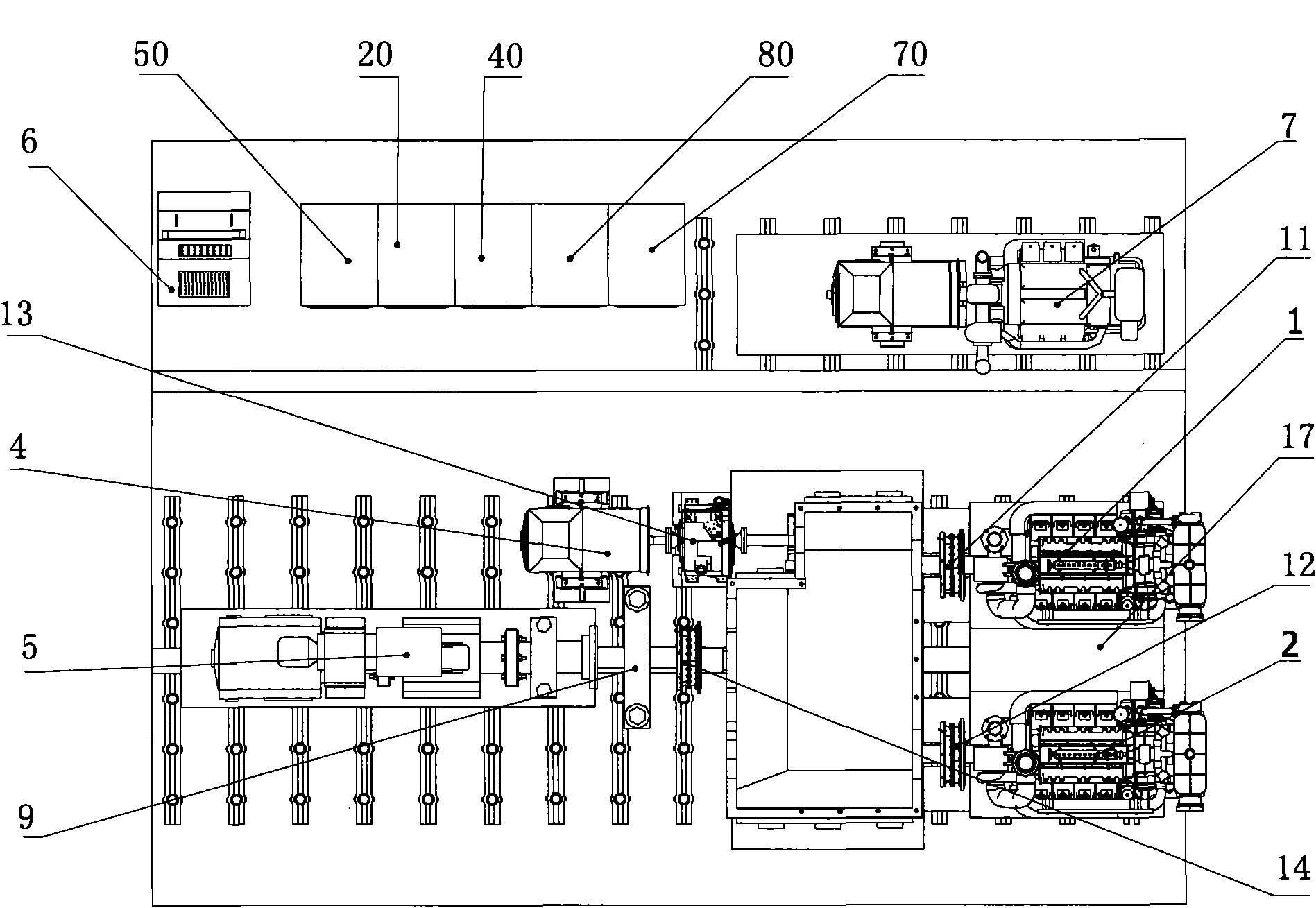

[0040] like Figure 1 to Figure 4 As shown, the ship propulsion power system test platform of the present invention includes a main propulsion diesel engine, a parallel gearbox 3, a shaft motor 4 with two operating modes of PTO / PTI, a propeller simulation device 5, a control device 6, a conventional diesel generator Unit 7, power consumption device 8.

[0041] The main propulsion diesel engines are two high-speed diesel engines 1 and 2.

[0042] The parallel gearbox 3 is a two-input and two-outlet type, that is, it is provided with two power input ends and two power output ends. It is used to parallel two high-speed diesel engines 1 and 2.

[0043] Two high-speed diesel engines 1 and 2 realize the power output after parallel operation through the parallel gearbox 3 .

[0044] like Figure 5 As shown, the high-speed diesel engine 1 is connected to the input terminal A1 of the parallel gearbox 3 through the transmission connector 11, and the high-speed diesel engine 2 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com