Process module facility

A technology of process modules and facilities, applied in metal material coating process, ion implantation plating, gaseous chemical plating, etc., can solve the problems of the bottleneck of the second film layer, difficulty in large substrate transmission and use, complex mechanical design, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

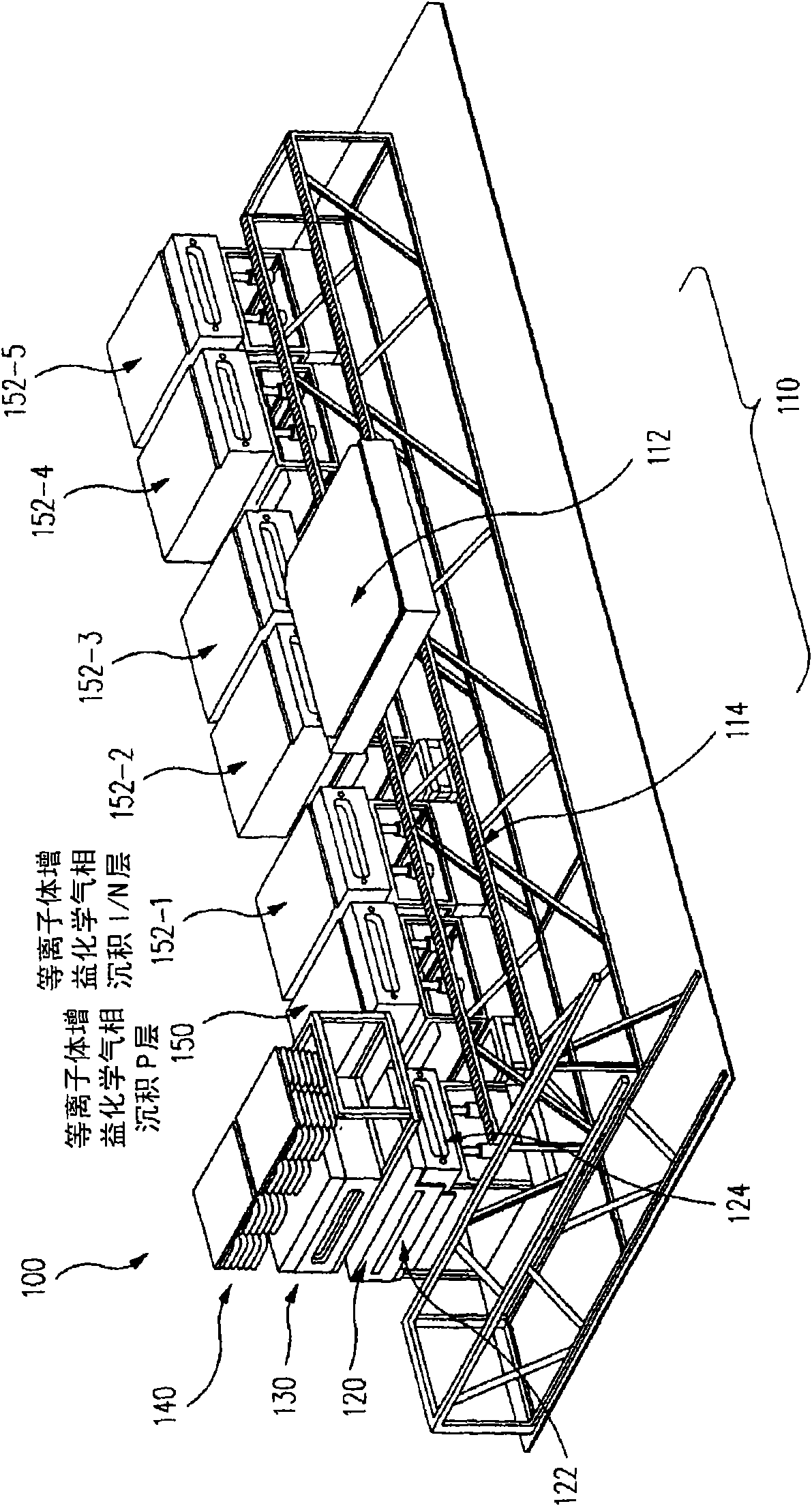

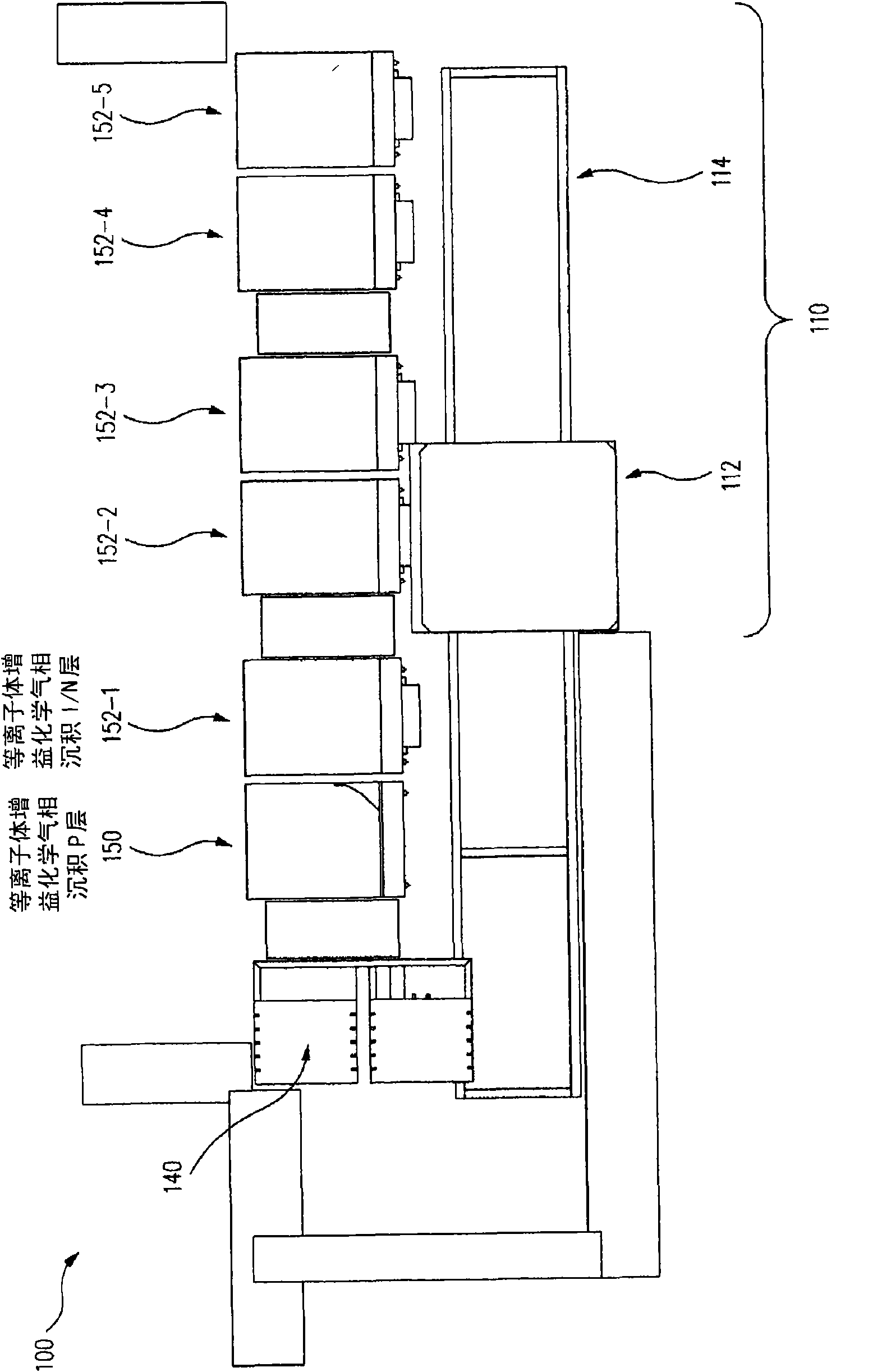

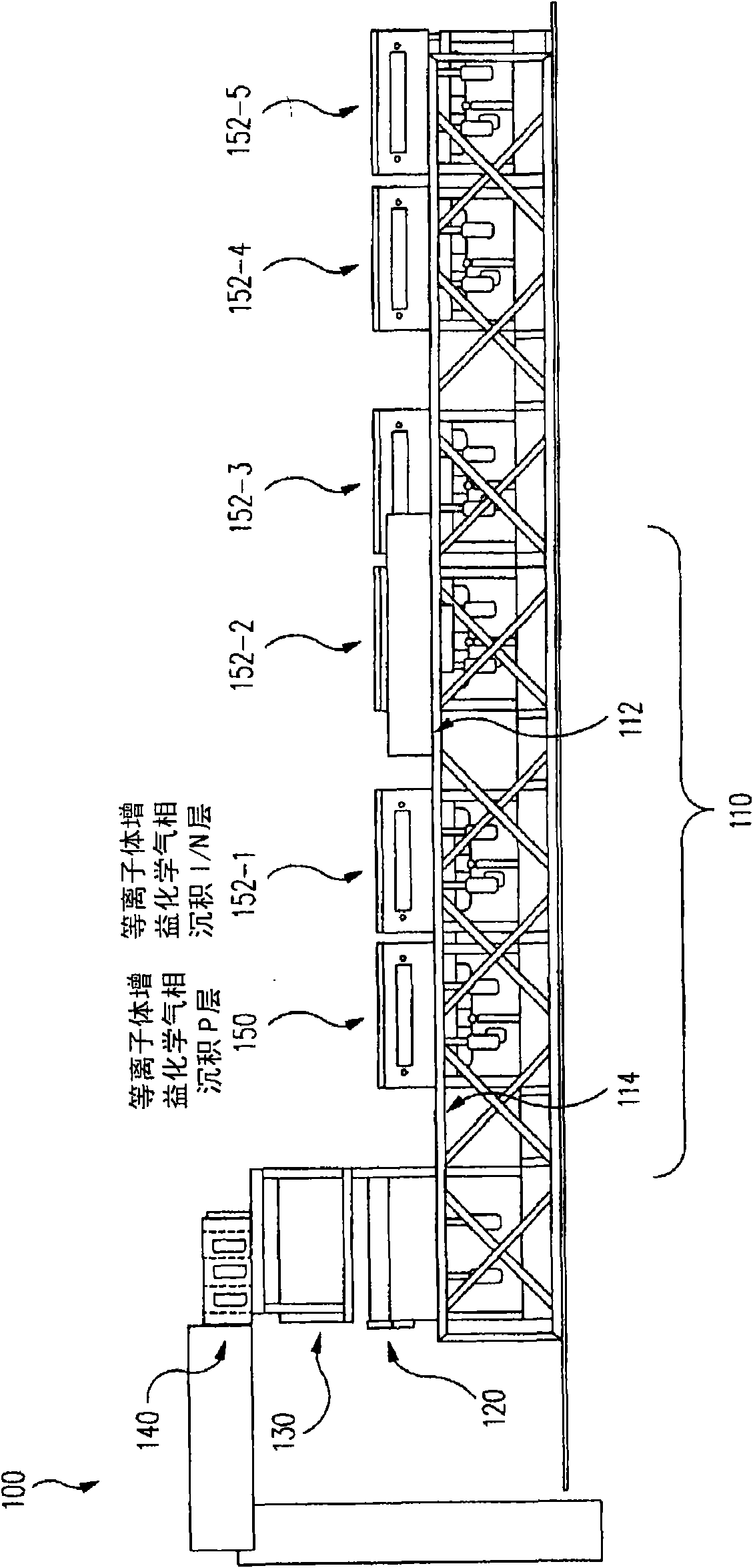

[0052] In general, embodiments described herein relate to systems and methods of processing boards, such as glass and other substrates for the solar or photovoltaic industries, and wafers for the semiconductor industry, but the invention is not limited thereto. More particularly, some embodiments described herein relate to systems and methods for processing substrates that include one or more mobile transverse chambers for transporting substrates between process modules and other stations, such as loading and unloading stations.

[0053] In some embodiments, a system for processing a substrate is provided, comprising: one or more mobile transverse chambers for moving between two or more process modules, and transporting one or more substrates to the two or more process modules at least one of the . Each mobile transverse chamber independently maintains a specific gas condition while moving between process modules and when one or more substrates are transported to the process m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com