Electromagnetic actuator of capsule robot

A technology of electromagnetic drive and capsule robot, applied in the direction of electromechanical devices, electrical components, etc., can solve the problems of low efficiency, inconvenient practical application, complex drive structure and capsule control process, etc., achieve small size, improve utilization rate, and low power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

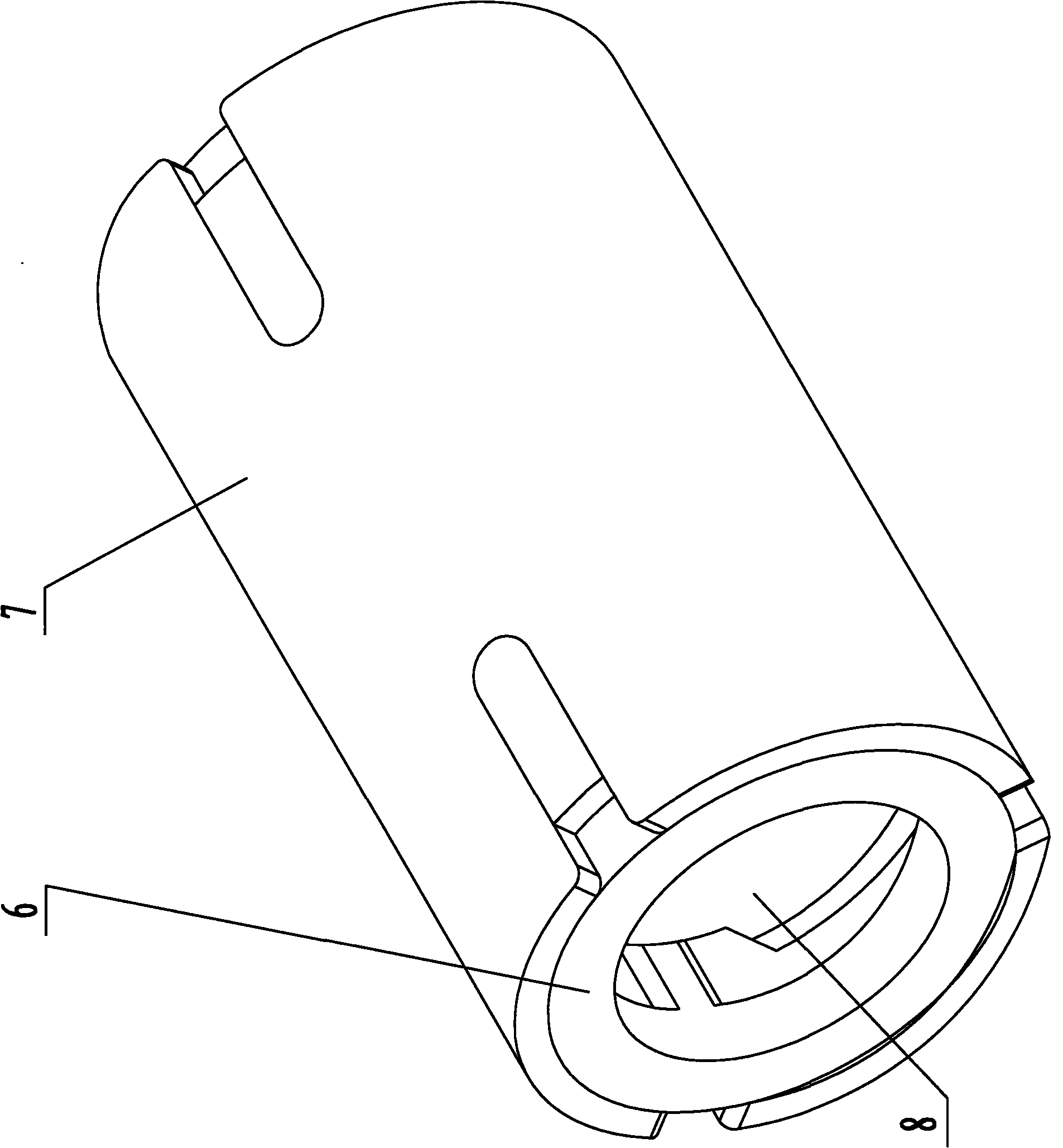

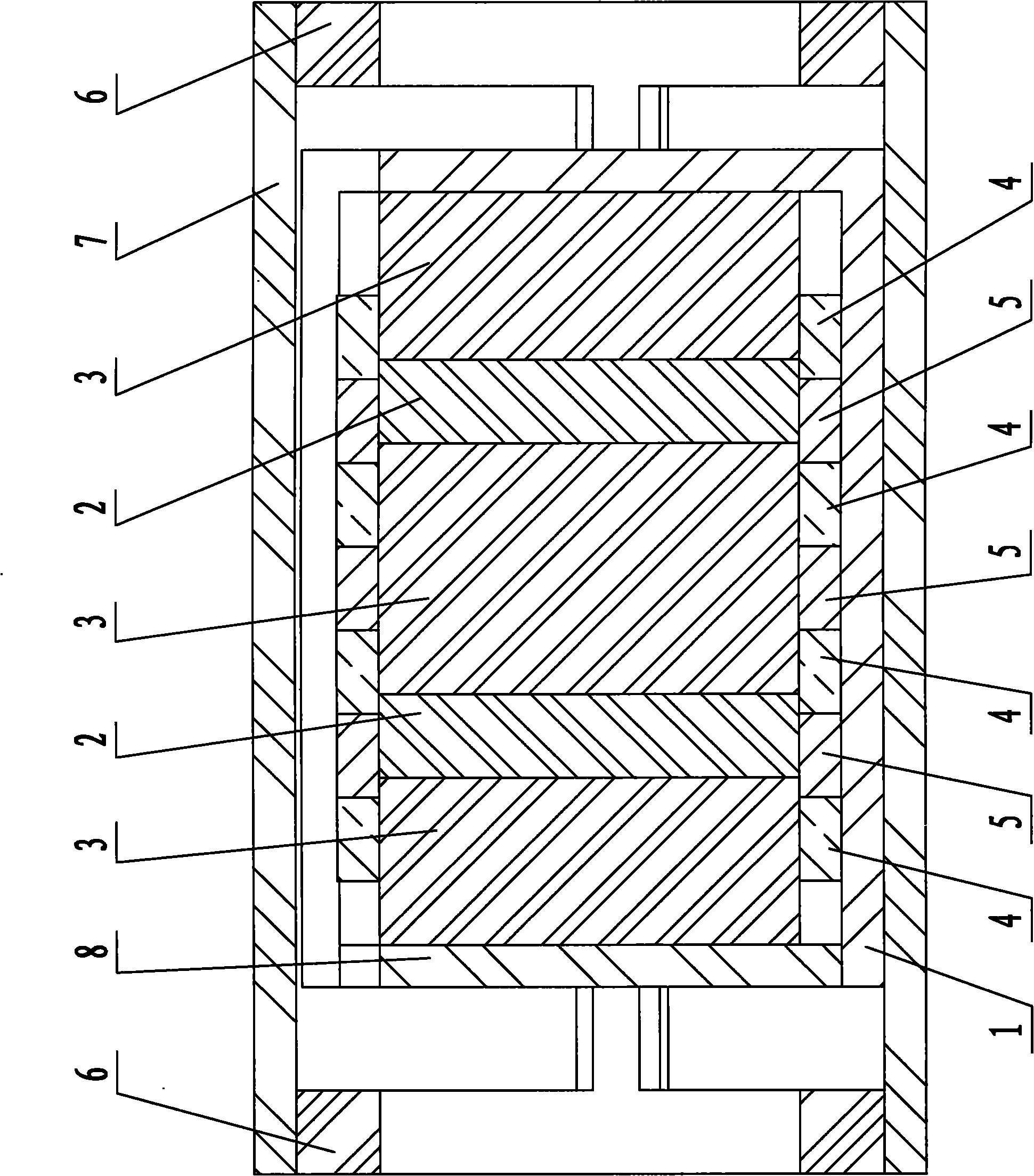

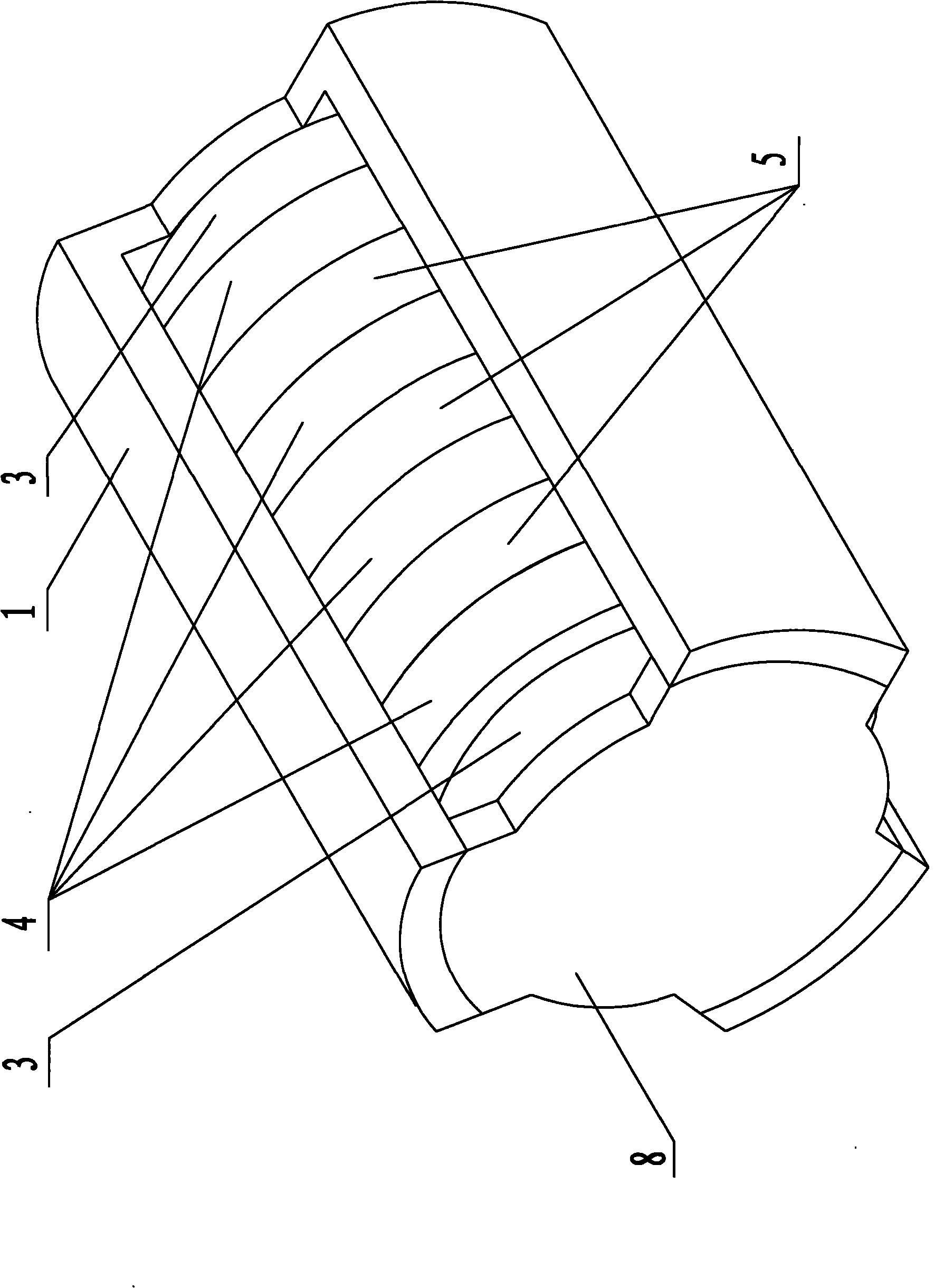

[0021] like Figure 1~3 As shown, the present invention includes a stator and a mover, wherein the bracket 6, the shell 7, the coil 4 and the gasket 5 are glued and fixed together as the stator, the magnetizer 1, the magnet gasket 2, the magnet steel 3 and the magnet end cover 8 Glued together as movers. The magnetizer 1 is located in the shell 7 with brackets 6 at both ends, the magnetometer 1 is equipped with a magnetometer 8, and the space formed by the magnetometer 8 and the magnetometer 1 is provided with a plurality of magnets 3 and conductors at intervals. Magnetic spacer 2 (the present embodiment is three pieces of magnetic steel, two pieces of magnetic spacers), magnetic steel 3 and magnetic spacer 2 are coaxially placed with magnetic body 1, between magnetic steel 3 and magnetic spacer 2 and A plurality of coils 4 and washers 5 are provided at int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com