Gas supply device

A technology for gas supply and gas treatment, which is applied in the fields of electrical components, gaseous chemical plating, semiconductor/solid-state device manufacturing, etc. The effect of a small diffusion space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

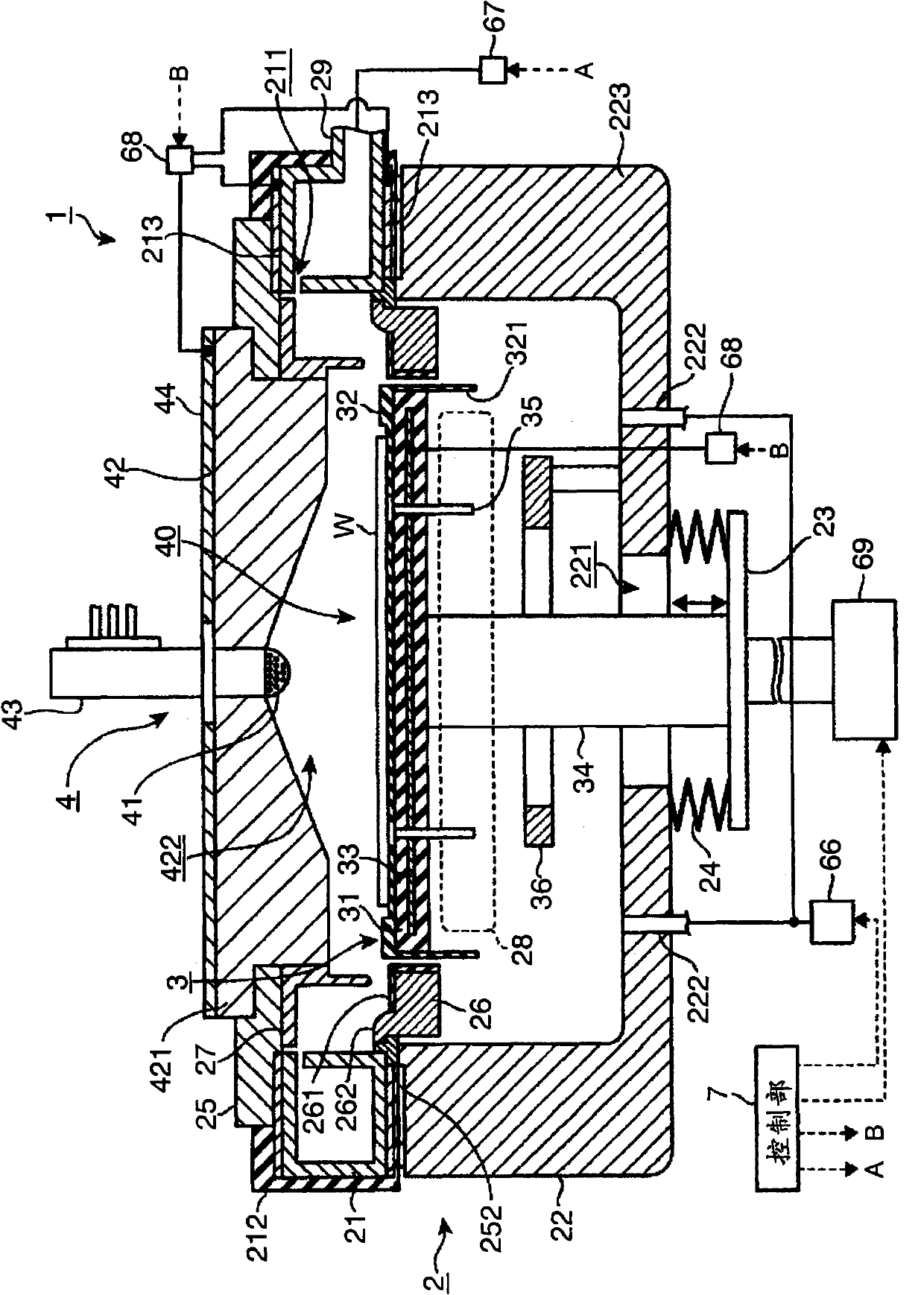

[0136] like Figure 18 As shown, in the film forming apparatus 1 of the above-mentioned embodiment, the space through which the gas flows (the circulation space 430, the inside of the gas supply nozzle 41, and the diffusion space 40 (processing ambient gas)) is created on the basis of the central position of the space. A model space that is divided into four in the circumferential direction. Then, a simulation was performed in which the concentration of the processing gas in the model space was increased from 0 vol% to 4.0 vol% by supplying the processing gas.

[0137] At this time, the concentration distribution of the processing gas at the time of 0.01 second after the start of the supply of the processing gas was obtained. When the processing gas is supplied, in order to prevent back diffusion of the gas, a reverse gas is supplied simultaneously with the processing gas. exist Figure 18 In , the processing gas is supplied from the position indicated by the solid line arr...

Embodiment 1-2

[0144] Under the same conditions as in (Example 1-1), the concentration distribution of the processing gas at the time of 0.1 second after the start of supply of the processing gas was obtained.

Embodiment 2-1

[0146] A simulation was performed in which a purge gas was supplied to reduce the concentration of the processing gas from 4.0 vol% to 0 vol% in the phantom space after the processing gas was supplied under the conditions of (Example 1-1) and (Example 1-2).

[0147] The processing gas concentration distribution at the time of 0.01 second elapsed from the start of the supply of the processing gas was obtained. Figure 18 The solid line (hereinafter referred to as the processing gas pipeline) and the dotted line (hereinafter referred to as the reverse filling gas pipeline) are supplied with argon as a purge gas.

[0148] Process gas pipeline supply

[0149] Argon 500mL / min(sccm)

[0150] Reverse fill gas line supply

[0151] Argon 1500mL / min(sccm)

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap