Multifunctional working rigmachine used on a dry field

A multi-functional, working machine technology, applied in the field of agricultural machinery, can solve the problems such as the inability to carefully judge the state of crops with vision, the inability of the locomotive height to play a role, and the adjustment of the distance between the tractor wheels. The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

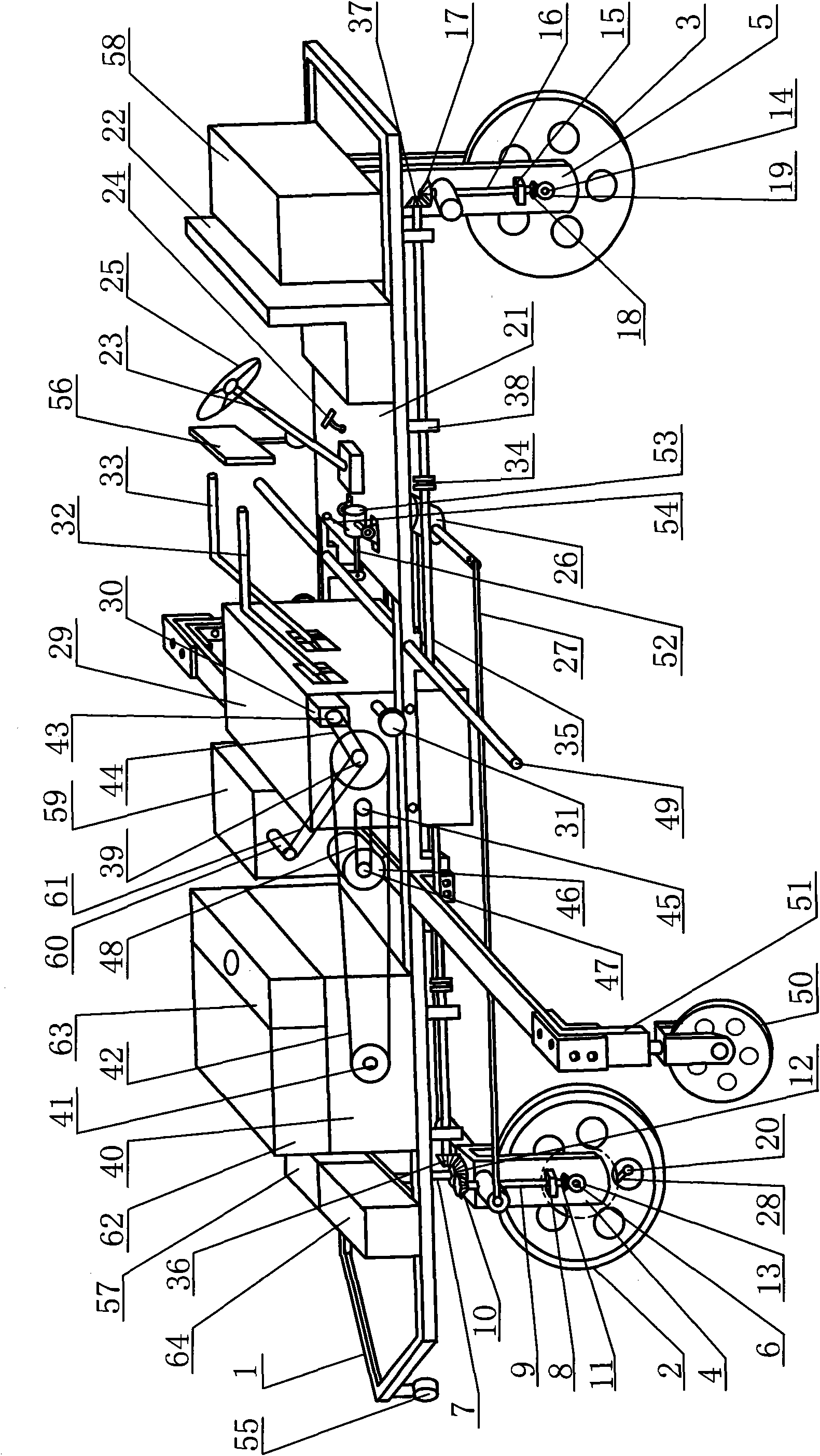

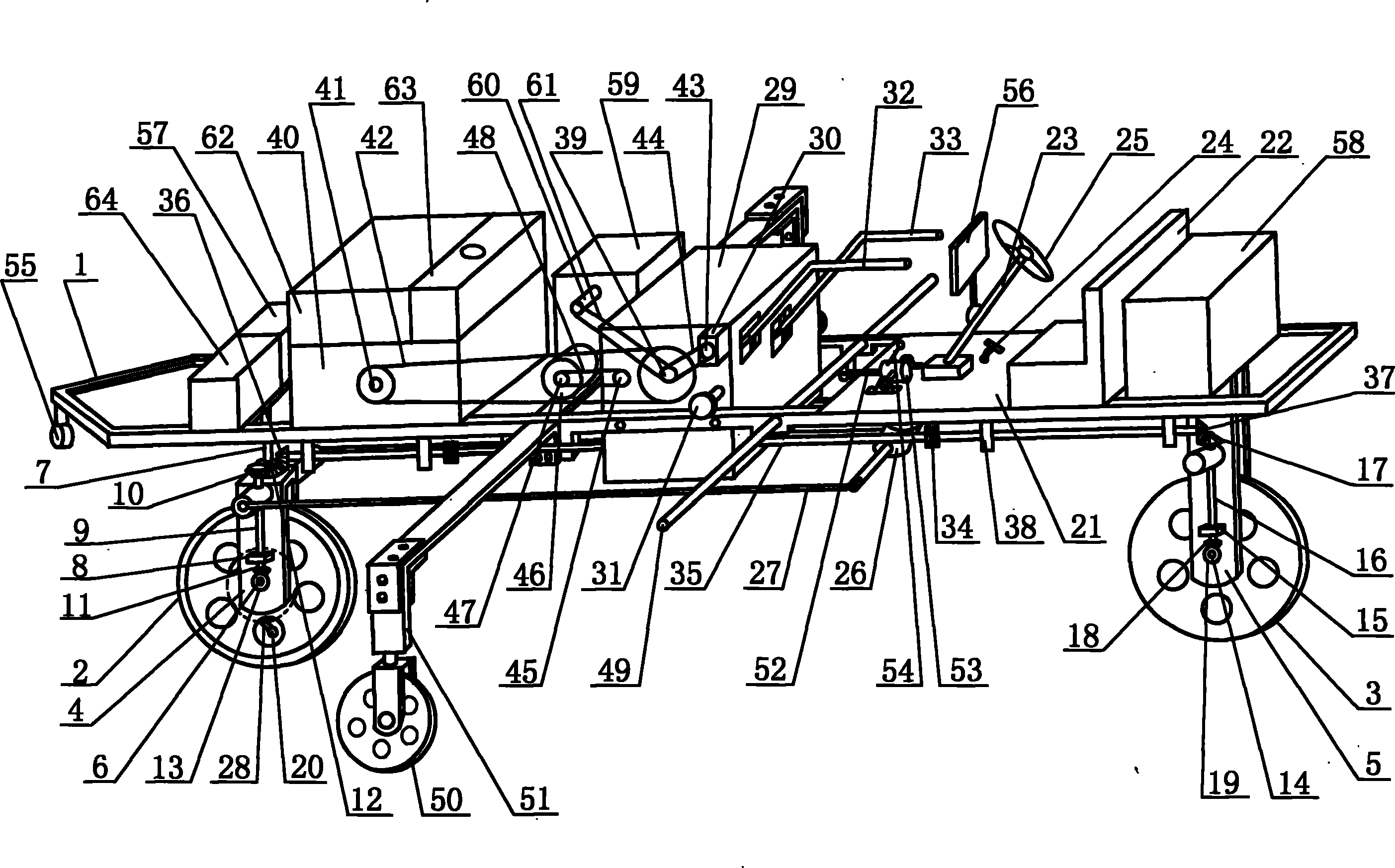

[0014] Such as figure 1As shown, the dry field multifunctional work machine provided by the present invention includes a vehicle frame, and the vehicle frame is provided with a driving mechanism composed of a fuel tank 62, a water tank 63, an engine 40, a gearbox 29, an operating console 21, a steering gear, wheels and brakes. device and generator 46 and storage battery 57, wherein said vehicle frame 1 underside is provided with a front wheel 2 and a rear wheel 3, said front wheel 2 and rear wheel 3 are located on the same straight line, front wheel 2 and a rear wheel 3 A fork-shaped front wheel bracket 4 and a rear wheel bracket 5 are respectively arranged between the rear wheel 3 and the vehicle frame 1, and a front wheel connecting shaft 6 and a connecting rod 7 are respectively arranged between the front wheel bracket 4 and the front wheel 2 and the vehicle frame 1. , the retaining seat 8 provided on the front wheel bracket 4 is provided with a front connecting rotating ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com