Portable multifunctional double-wire self-protecting flux-cored wire welding device

A flux-cored welding wire and welding equipment technology, which is applied to welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of inconvenient use, and achieve the effects of strong anti-interference ability, beautiful weld shape, and good synergy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with drawings and embodiments.

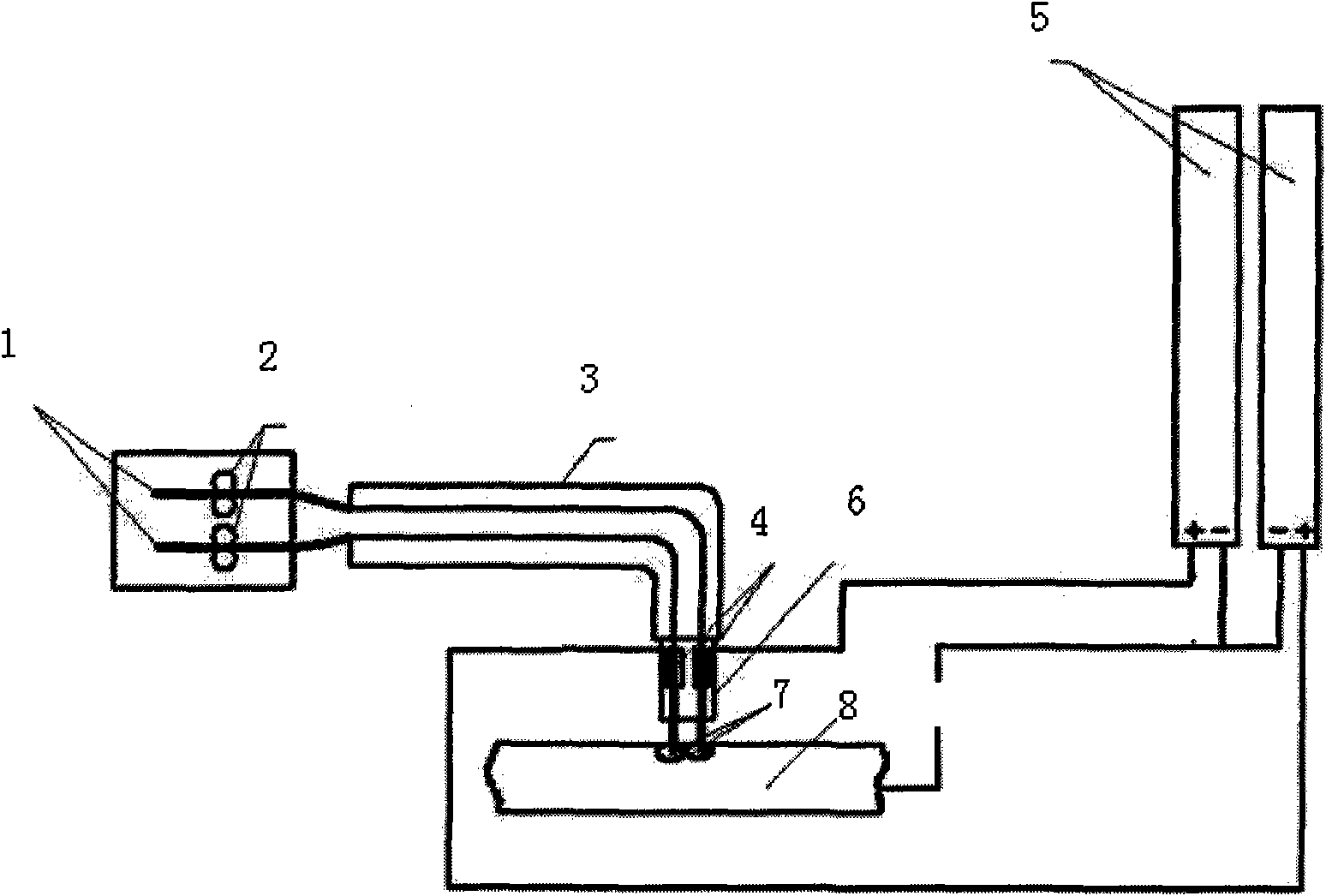

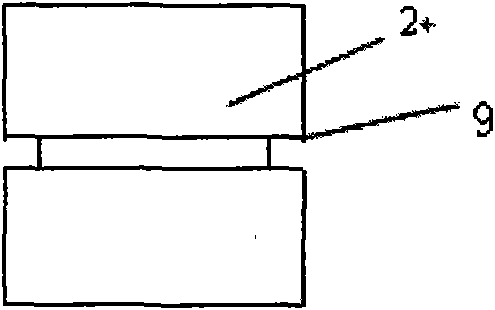

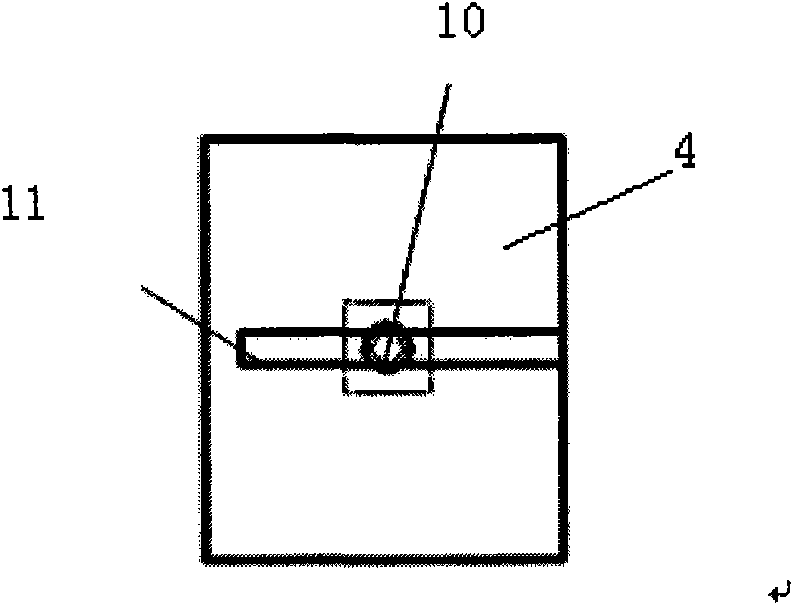

[0011] The welding machine of the invention is matched with a portable IGBT double-wire welding inverter power supply. Such as figure 1 As shown, the portable multi-functional double-wire self-shielded flux-cored welding equipment, 1. Flux-cored wire; 2. Wire clamping mechanism; 3. Portable welding torch body; Power supply 6. Hand-held welding torch head with adjustable wire pitch, 7. Welding double molten pool, 8. Welded steel rail. The welding wire pinching mechanism is an integrated self-shielding flux-cored wire double-wire wire-feeding mechanism with smooth wire feeding. In order to protect the flux-cored welding wire from being crushed and damaged, each wire feed roller has the following figure 2 The U-shaped groove 9 shown. The hose can be connected between the wire feeding mechanism and the gun body of the welding torch, and the flux-cored welding wire pass...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap