Method for amination of carbon nano tube

A carbon nanotube and amination technology, applied in the field of amination, can solve the problems of complex process and low efficiency of nitrogen-containing functional groups, and achieve the effect of simple process and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0009] Specific Embodiment 1: The method for amination of carbon nanotubes in this embodiment is carried out according to the following steps: 1. Put 0.2-0.5 g of pretreated carbon nanotubes into a supercritical reactor, and then add 20-24 ml of Ammonia water or 20-24ml of ethylenediamine, the temperature of the supercritical reactor is controlled at 340-350°C, the pressure is 6-11MPa, the reaction time is 2-4min, and the reactor is cooled with water; After washing with distilled water, vacuum-drying at 55-65° C. to obtain aminated carbon nanotubes.

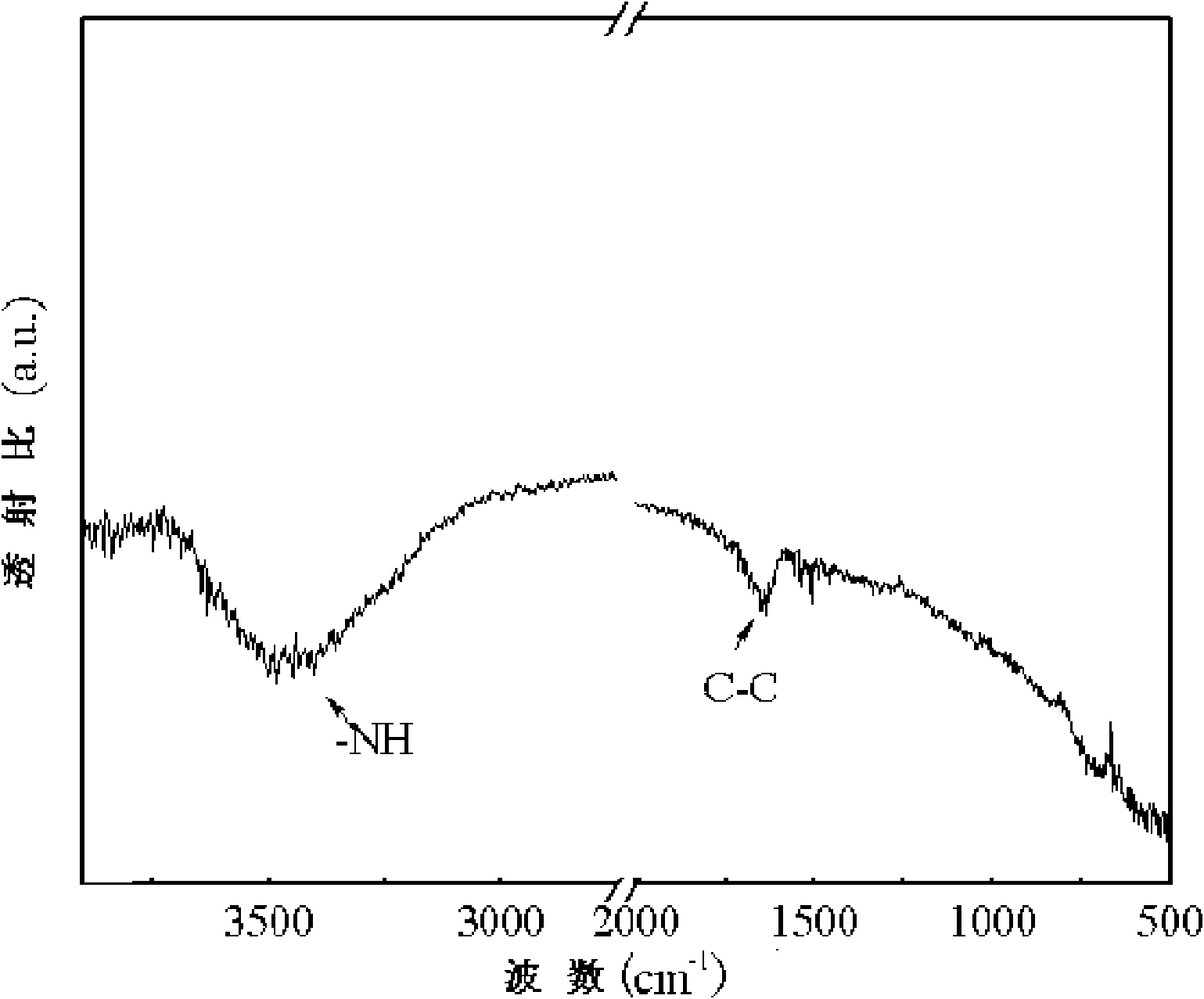

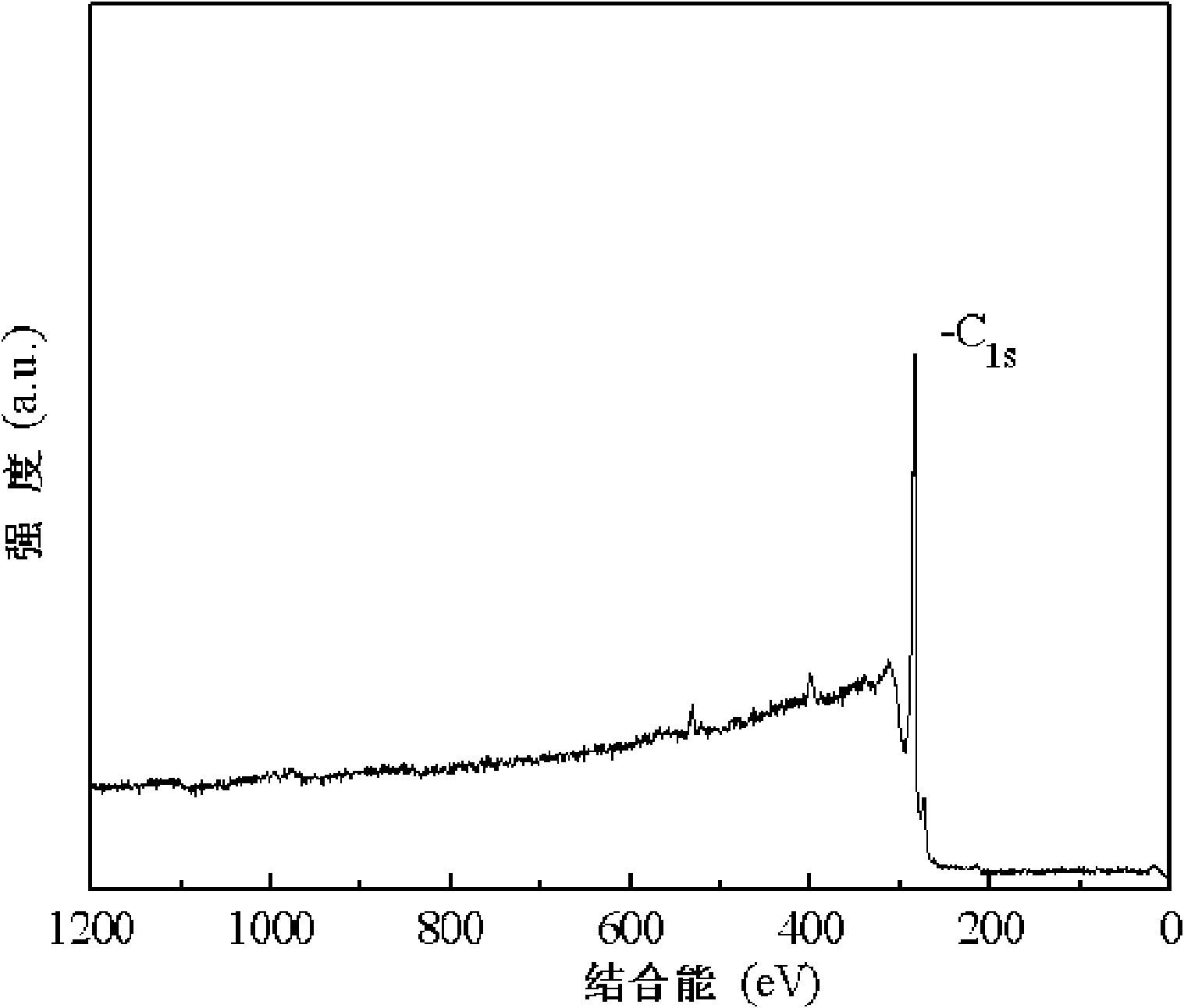

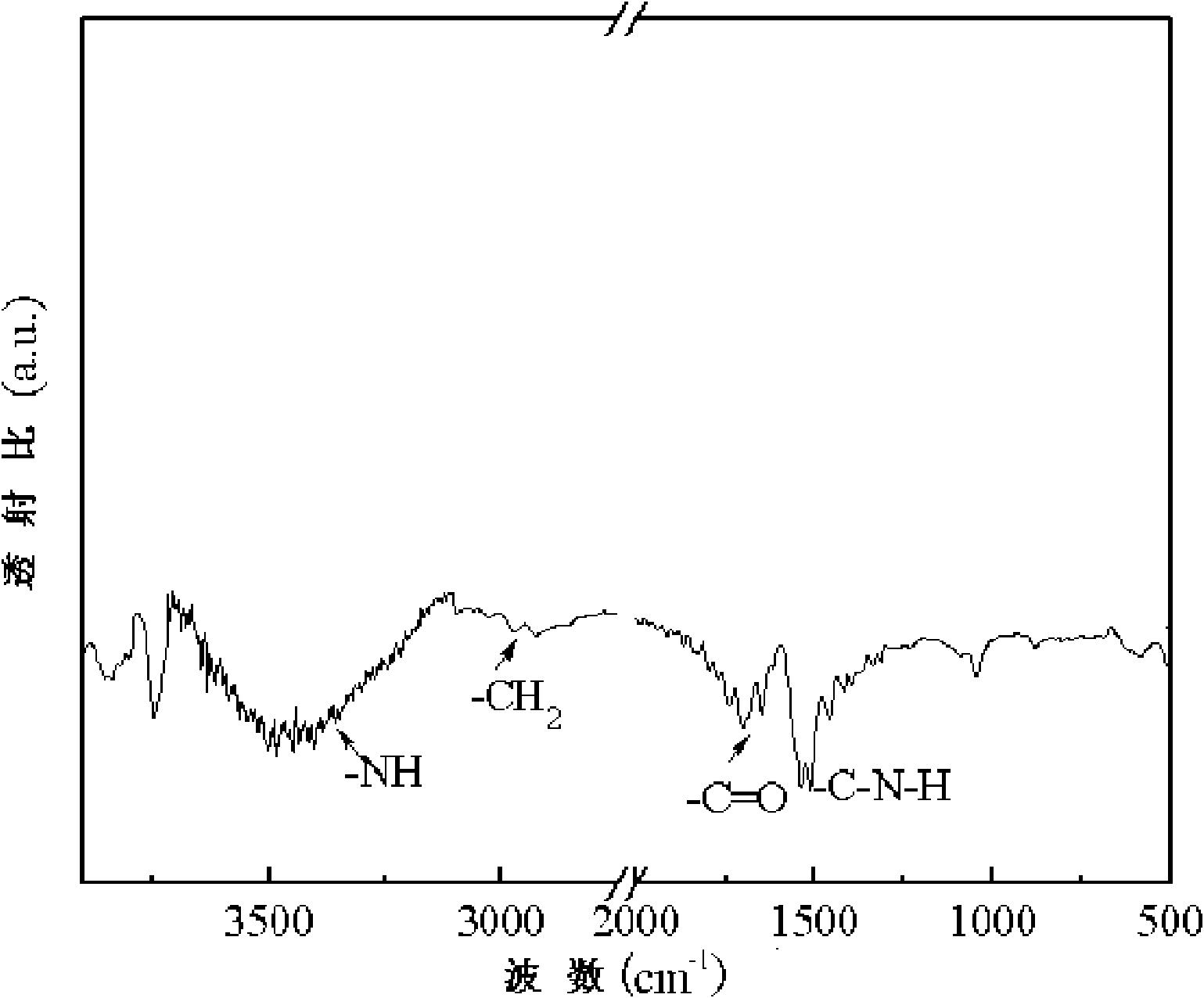

[0010] The process of the method of this embodiment is simple, and the carbon nanotubes after amination in this embodiment can be seen by infrared spectrum, and there is obvious -CH on the carbon nanotubes by infrared spectrum. 2 , -C=O, -C-N-H absorption peaks, it can be inferred that the amine group is grafted to the carbon nanotubes, and the aminated carbon nanotubes in this embodiment can be known by red X-ray photoelectron s...

specific Embodiment approach 2

[0011] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the pretreatment method in step 1 adopts purification treatment, and the specific operation is: burning the carbon nanotubes at 300-400 °C for 5-7 hours, that is The pretreated carbon nanotubes are obtained. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0012] Specific embodiment three: the difference between this embodiment and specific embodiments one to two is that the pretreatment of carbon nanotubes in step one adopts the method of acid treatment, and the specific operation is: a, carbon nanotubes are burned under the condition of 300-400 ° C 5~7h; b. Mix 250ml of mixed acid and 0.3~0.6g of carbon nanotubes treated in step 1, and sonicate for 5~7h at a frequency of 80~100Hz and a temperature of 45~55°C. h 2 SO 4 with concentrated HNO 3 According to the volume ratio of 3:1; c, after ultrasonic cleaning, wash with distilled water, and then use 0.45 μm microporous membrane to filter, and the precipitate obtained by suction filtration is vacuum-dried at 55-65 ° C to obtain the pretreated The carbon nanotubes are washed with distilled water for 3 to 5 times, and the standing time for each cleaning is 22 to 26 hours. Other steps and parameters are the same as those in Embodiments 1 to 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com