Chip fixing glue for LED (Light Emitting Diode)

A technology of solid crystal glue and silica gel, which is applied in the direction of adhesives, adhesive additives, electrical components, etc., can solve the problems that are difficult to meet the reliability requirements of packaged LEDs, and achieve the advantages of LED chip bonding, low fluidity, and low ionization. The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

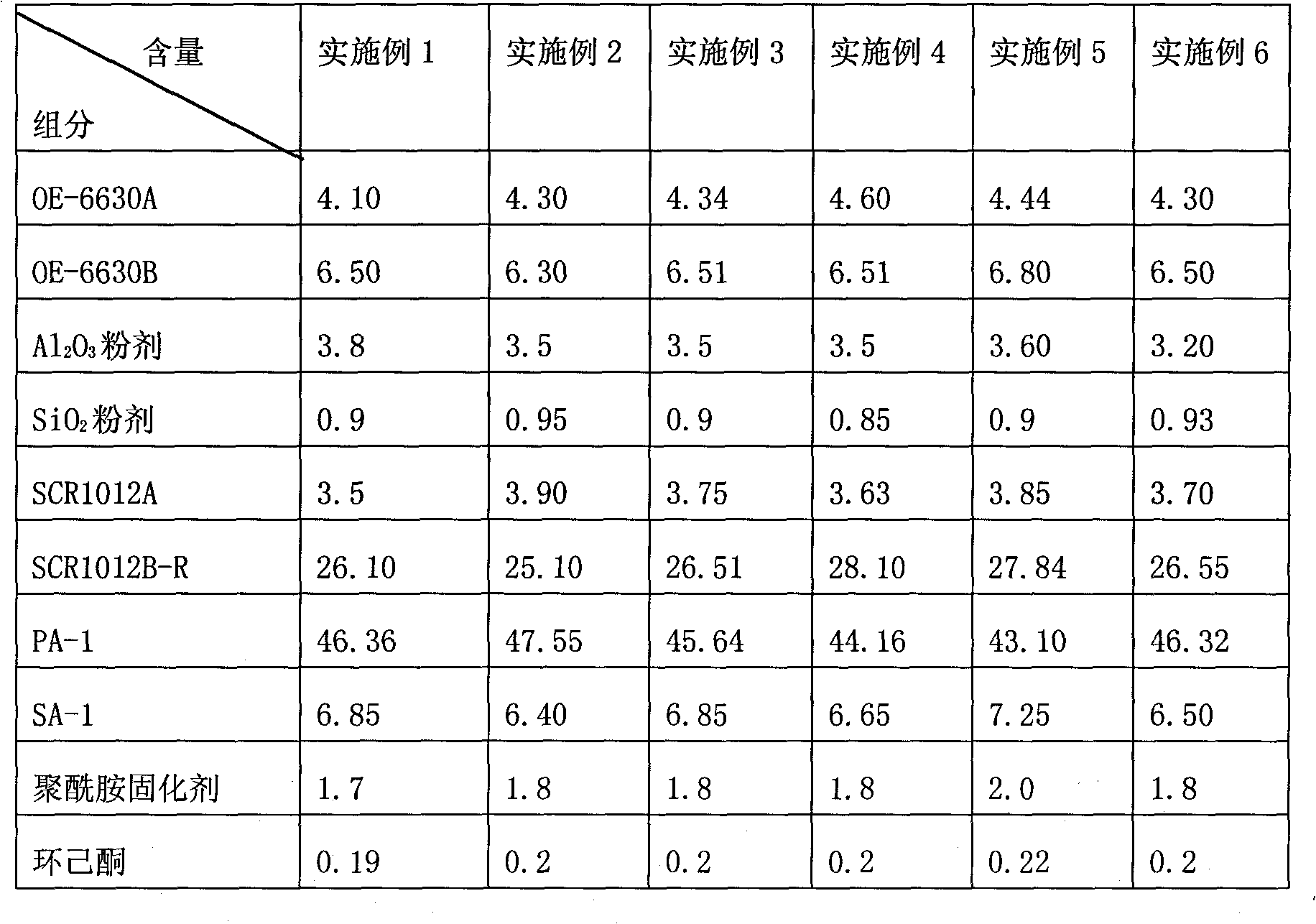

[0039] In order to further describe the present invention, the LED die-bonding adhesive of the present invention will be further described below in conjunction with examples.

[0040] According to the components and contents (% by weight) listed in Table 1, the LED die-bonding glue was prepared. All components are commercially available.

[0041] Table 1 Components and content of LED die-bonding glue (100% by weight)

[0042]

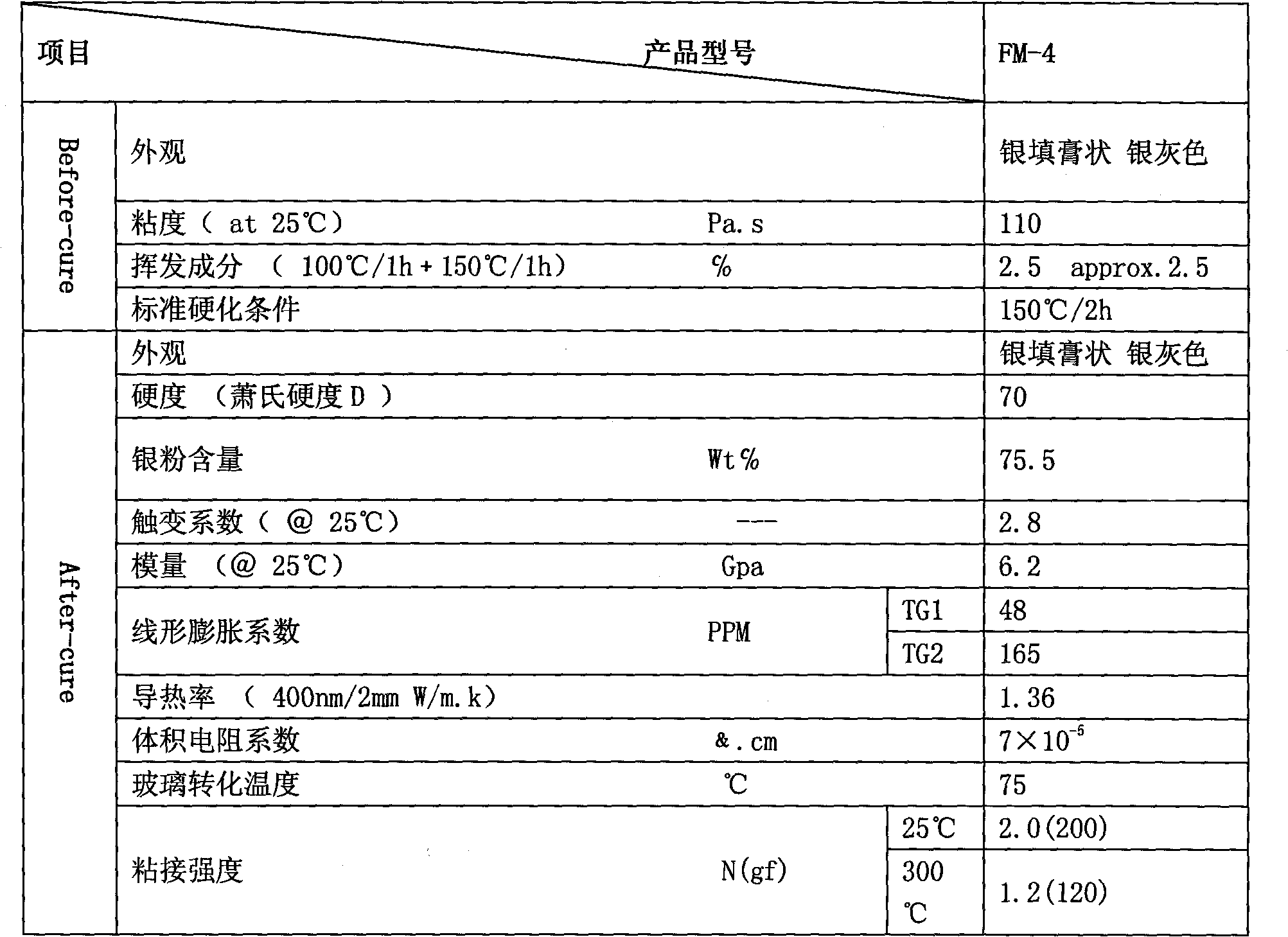

[0043] The properties of the LED die-bonding adhesive in Example 3 are shown in Table 2.

[0044] Table 2 Product performance of LED die-bonding adhesive

[0045]

[0046] (Note: Before-cure: before baking; After-cure: after baking)

[0047] After testing, the properties of the LED die-bonding adhesives obtained in Examples 1, 2, 4, 5, and 6 are basically the same as those in Table 2.

[0048] The method of use is as follows:

[0049] A. Take out a certain amount of LED crystal-bonding glue from the freezer and put it in an anti-static bag, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com