Wall body door or window hole structure

A technology for doors, windows, openings, and walls, which is applied to building structures, walls, windows/doors, etc., can solve the problems of unfavorable energy saving and heat preservation of walls, affect the durability of walls, and poor waterproofing of openings, etc., to reduce thermal bridges at openings Heat transfer, improve energy saving and heat preservation level, good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

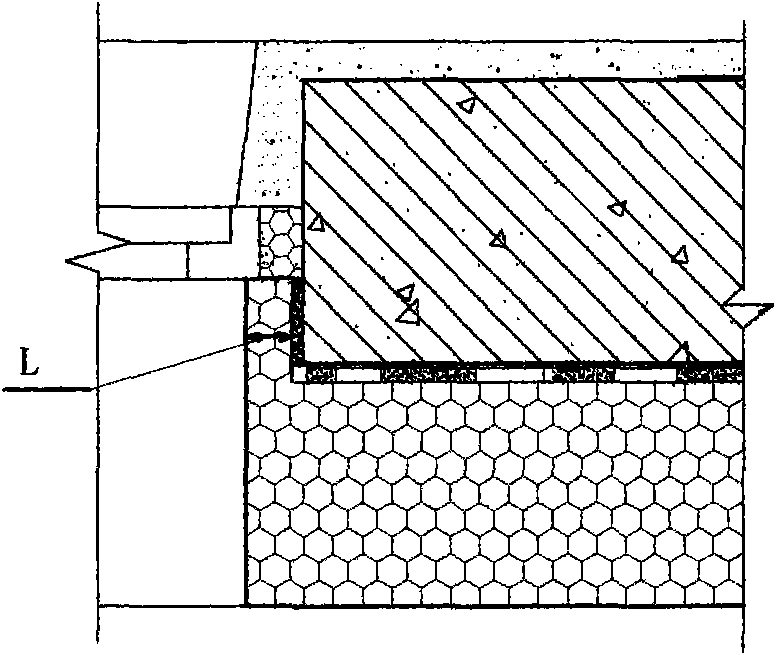

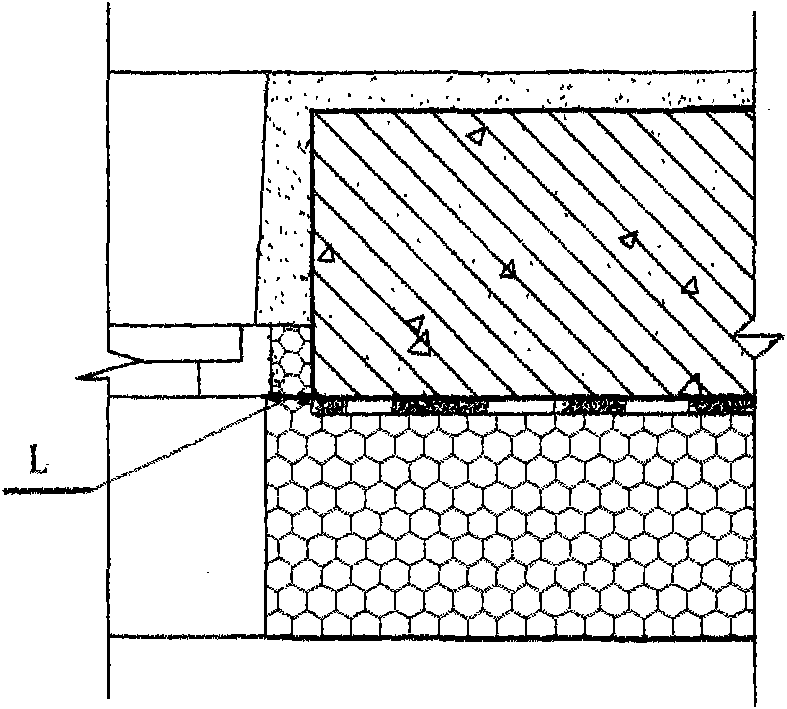

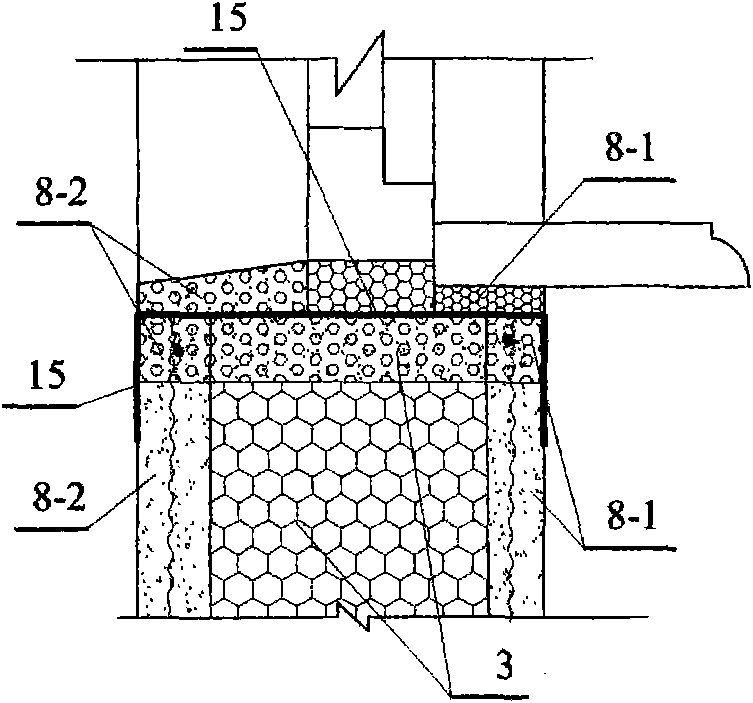

[0029] Specific implementation mode one: see image 3 , Figure 4 , a wall door and window opening structure of the present embodiment is made up of insulation layer 3, indoor protection layer 8-1, outdoor protection layer 8-2, doors and windows 20; described insulation layer 3 is polymer insulation material or mineral wool or plant Straw or paper honeycomb board or thermal insulation masonry or thermal insulation mortar; the indoor protective layer 8-1 and outdoor protective layer 8-2 are cement mortar or fine stone concrete plastering layer, or modified cement mortar or fine stone concrete plastering layer Ash layer, or thermal insulation mortar; the thermal insulation layer 3 is located between the indoor protective layer 8-1 and the outdoor protective layer 8-2, and the thermal insulation layer 3 is bonded to the indoor protective layer 8-1 and the outdoor protective layer 8-2 respectively The doors and windows 20 are fixed on the insulation layer 3 of the door and window...

specific Embodiment approach 2

[0037] Specific implementation mode two: see image 3 The difference between the present embodiment and the specific embodiment one is that the present embodiment increases the waterproof layer 15; the waterproof layer 15 is pasted on the thermal insulation layer 3 of the window sill, or is also pasted on the thermal insulation layer 3 of the side wall of the hole, or On the insulation layer 3 around the hole, the waterproof layer 15 is pasted, and the waterproof layer 15 is overlapped with the indoor protective layer 8-1 and the outdoor protective layer 8-2. There are an indoor protective layer 8-1 and an outdoor protective layer 8-2 respectively, and the waterproof layer 15 is a polymer waterproof coiled material, forming a waterproof structure for thermal insulation and broken bridges in the openings of walls, doors and windows.

[0038] The key position of the waterproofing of door and window openings is the window sill, but it is more beneficial to paste waterproof layers...

specific Embodiment approach 3

[0044] Specific implementation mode three: see Figure 5 , Figure 6 The difference between this embodiment and the first or second embodiment is that the indoor protective layer 8-1 of this embodiment is a masonry wall or a concrete wall 8-1-1. Figure 5 and Figure 6 The insulation layer of the door and window openings is vitrified closed-cell perlite insulation mortar. Figure 5 The indoor and outdoor protective layers on both sides of the door and window profiles shown are also vitrified closed-cell perlite mortar. Figure 6 The indoor and outdoor protective layers on both sides of the door and window profiles shown are cement mortar. Heating areas should be Figure 5 As shown, the thermal insulation layer of the opening and the indoor and outdoor protective layers of doors and windows should be made of materials with good fire resistance and good thermal insulation; in hot summer areas, the protective layer of the opening can be ordinary cement mortar.

[0045] Backg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com