Calibration technology for vision sub-pixel of embedded type machine with optical path adjustment

An optical path adjustment and machine vision technology, which is applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problems of difficulty in determining the precise center grid of precise corner extraction, no application of industrial production, and no calibration implementation method, etc. Facilitate the use of subsequent measurements, strong practicability, and real-time feedback on the effect of adjustment results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

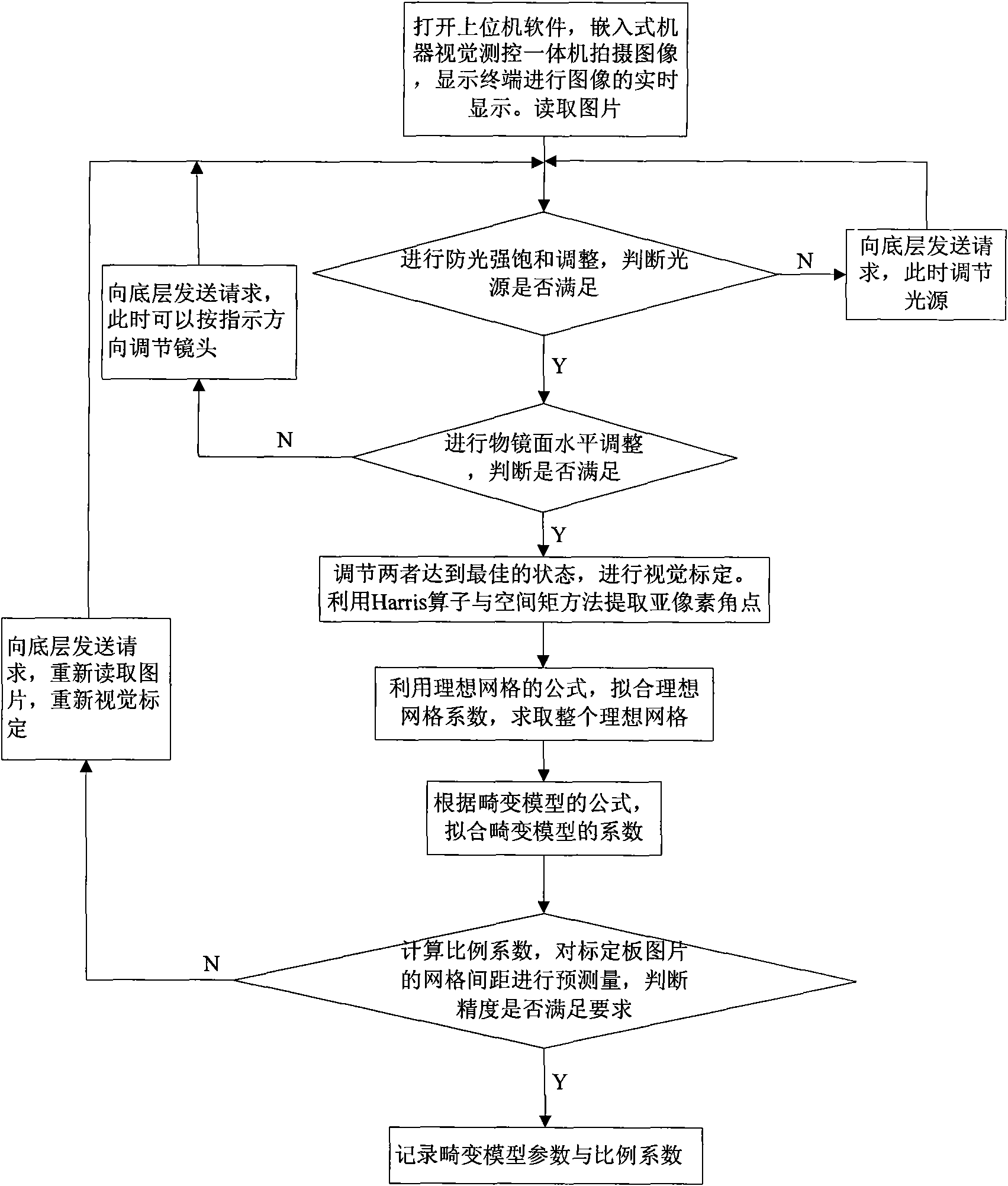

[0050] In order to reduce the influence of the industrial environment on the calibration and improve the calibration accuracy, the present invention develops a visual calibration technology. The calibration technology algorithm has small code size, fast operation speed, high precision, strong real-time performance, and good stability. It can improve the disadvantages of traditional measurement, reduce costs, and increase production speed.

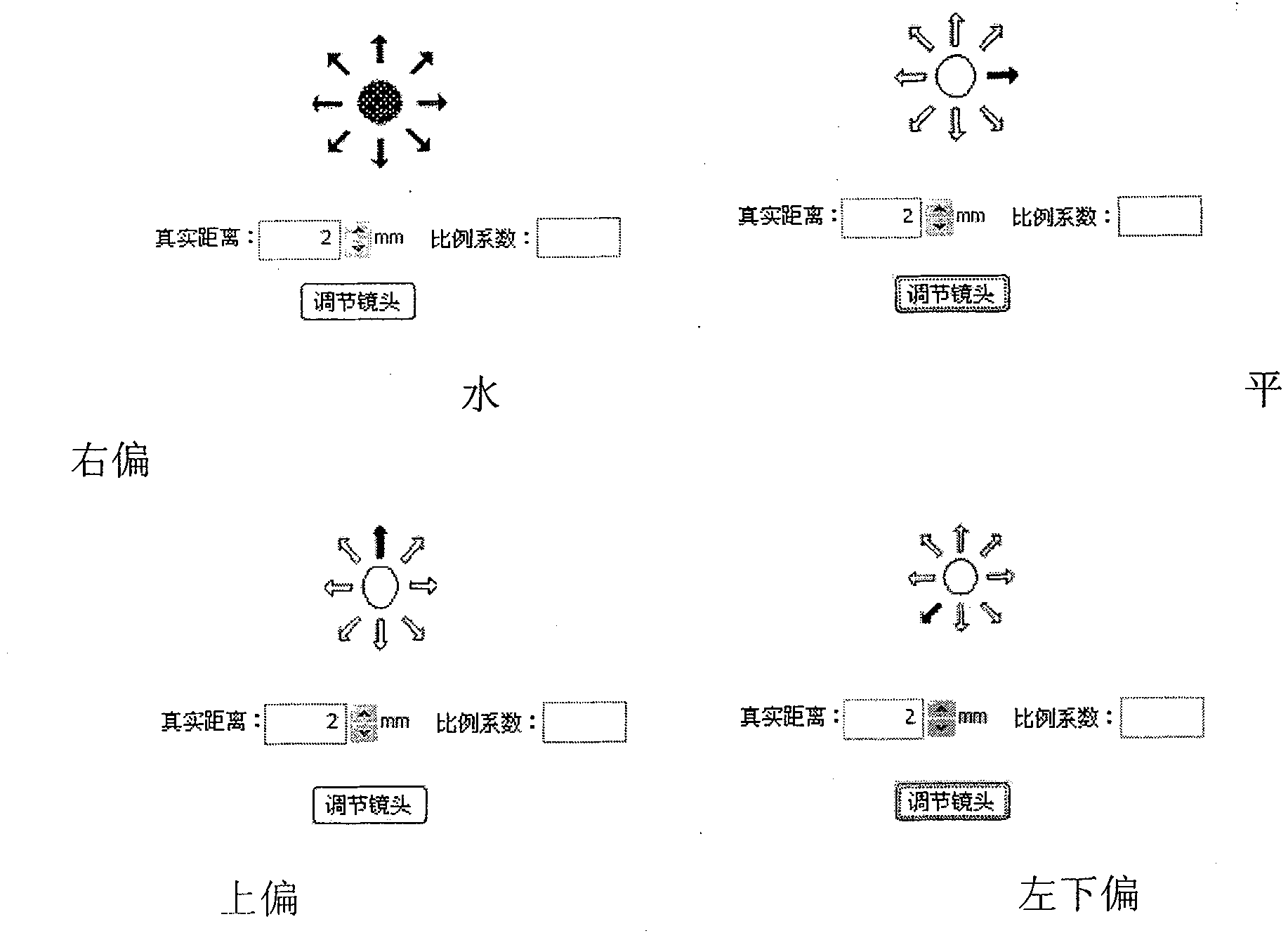

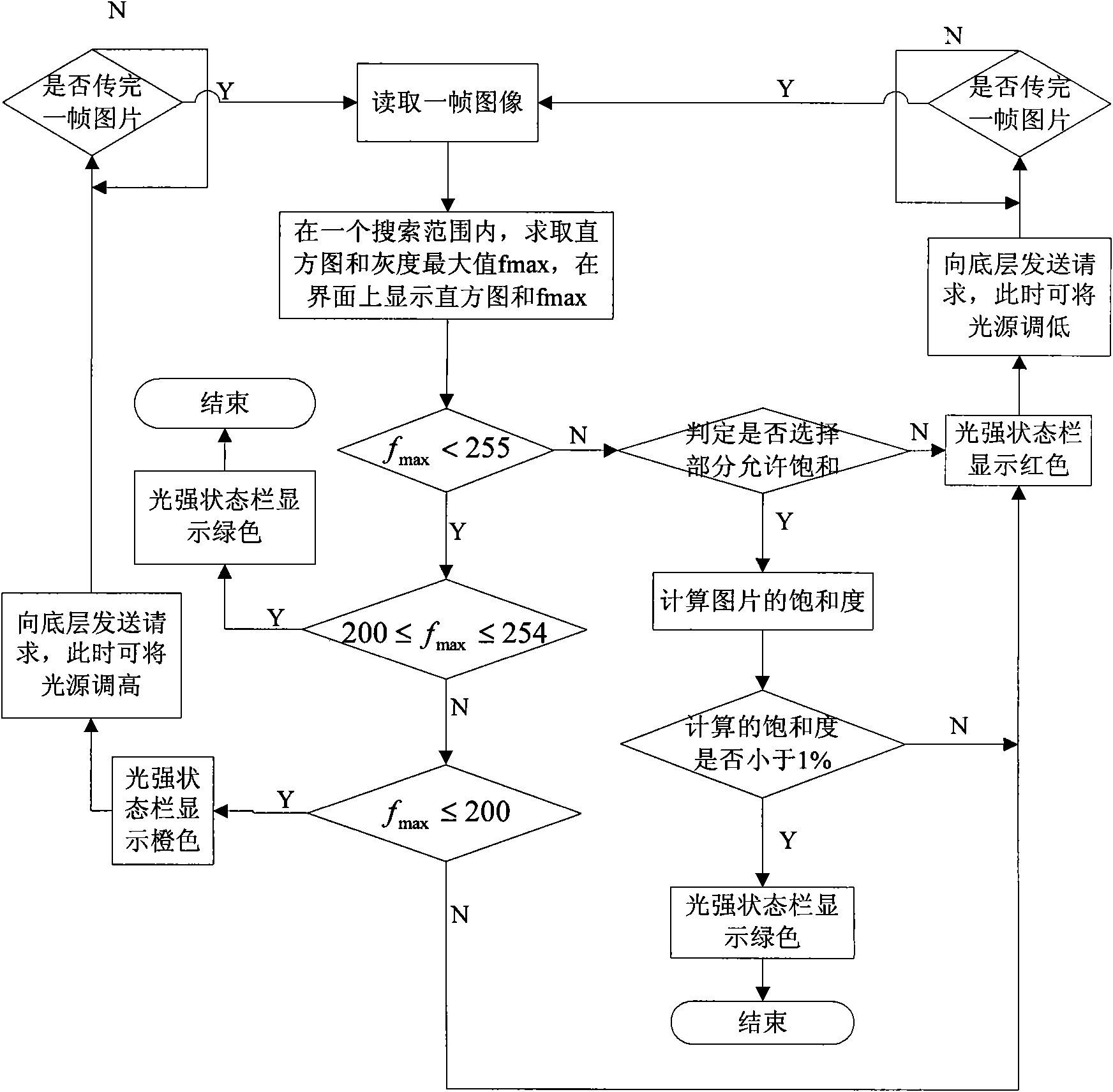

[0051] Aiming at the influence of the change of light intensity and the parallelism of the object mirror surface on the corner point extraction accuracy and the fitting accuracy of the distortion model, the present invention proposes a highly adaptable optical path adjustment system, including anti-light intensity saturation and parallel adjustment of the object mirror surface. The anti-light intensity saturation adjustment is to prevent the loss of edge information and inaccurate corner point extraction due to the light intensity saturation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com