Two-dimensional fiber bragg grating and preparing method thereof

A two-dimensional fiber and fiber grating technology, which is applied in cladding fibers, opto-mechanical equipment, optical waveguides and light guides.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

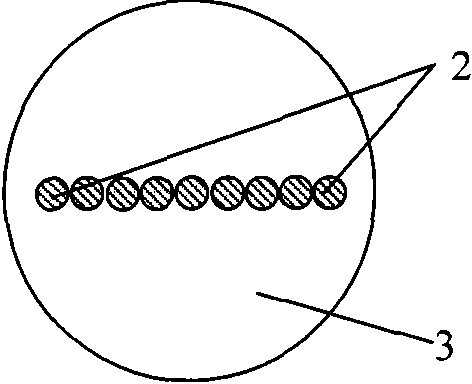

[0030] An embodiment of the method for manufacturing a linear array multi-core optical fiber of the present invention specifically includes the following steps:

[0031] A circular fiber core and hollow and solid cladding preforms of different sizes are manufactured by chemical vapor deposition, and multiple core preforms 5 are arranged in a linear array. Set it outside the linear array to center the linear array, and fill other gaps with cladding preforms 6 of different sizes; or grind an appropriate large-sized cladding preform into a D-shaped cladding preform 8, two D-shaped cladding preforms The gaps between 8 are filled with the fiber core prefabricated rod 5; wire drawing is carried out by a conventional method. The linear array multi-core optical fiber shown in Fig. 4(c) will be drawn. Figure 4(a) and 4(b) Schematic illustration of the fabrication method for the linear array multicore fiber.

Embodiment approach 2

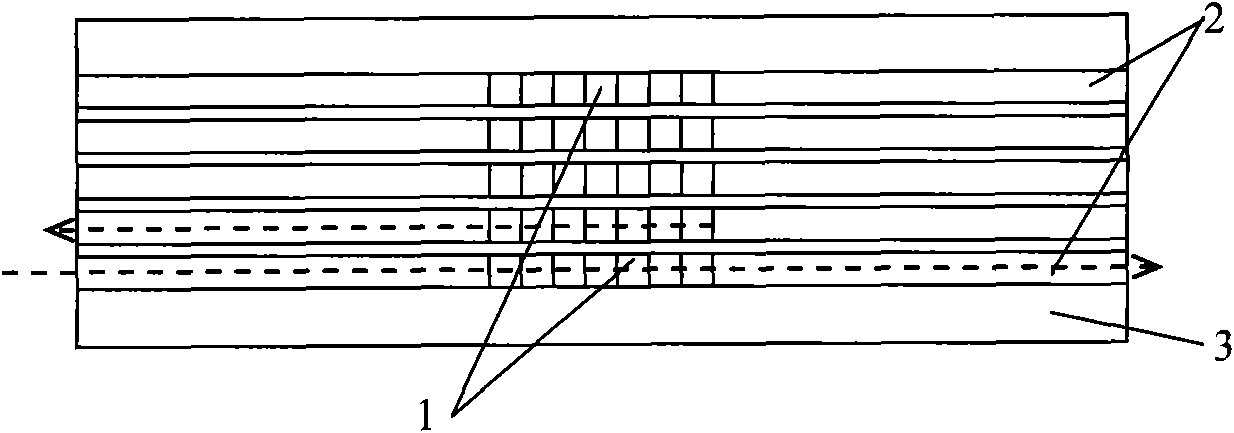

[0033] The embodiment of two-dimensional Bragg fiber grating manufacturing method of the present invention specifically comprises the following steps:

[0034] 1. Take a linear array multi-core optical fiber 13, the multiple cores have different photosensitivity, and strip the coating layer of the optical fiber with a length of 3-4cm;

[0035] 2. After cleaning, fix it on the optical fiber fixture, use a microscope to observe the position of each fiber core, and adjust the position of the optical fiber so that the phase mask 12 is close to the optical fiber 13, and the phase mask and the optical fiber are parallel to each other;

[0036] 3. Further make the plane of the fiber core parallel to the phase mask 12, the axis of the fiber is perpendicular to the line direction of the phase mask, and fix it after adjustment;

[0037] 4. One end of the optical fiber 13 is connected to a broadband light source by means of a beam splitter, and at the same time connected to a spectrum an...

Embodiment approach 3

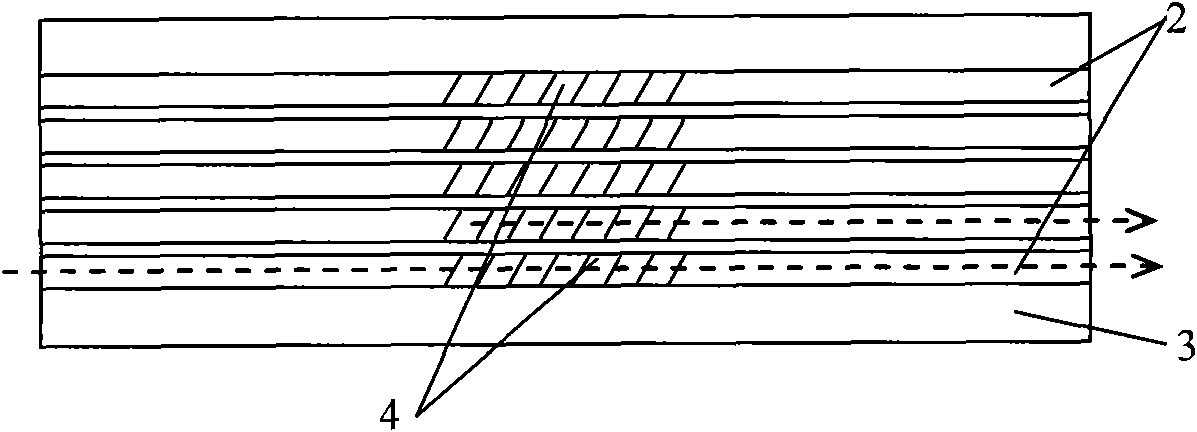

[0042] The embodiment of the manufacturing method of the two-dimensional obliquely blazed fiber grating of the present invention specifically includes the following steps:

[0043] Same as 1-2 in Scheme 2;

[0044] Adjust the phase mask 12 to be close to the optical fiber 13, so that the optical fiber and the phase mask 12 are parallel to each other, and there is an angle between the reticles of the phase mask and the multi-core optical fiber; then proceed to steps 4-6 in Scheme 2;

[0045] Carry out encapsulation, complete two-dimensional tilted blazed fiber grating (see figure 2 ) production.

[0046] The two-dimensional tilted blaze prepared by this scheme has different photosensitivity for different cores, and the refractive index of each core changes differently. Because the grating is a blazed grating, the reflected light of each grating is easily coupled into the nearby core. The angle is the same, the reflected light does not return according to the original path, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com