High-gain and high-power antenna based on materials with low refractive index

A low-refractive-index, high-gain technology, applied in the direction of antennas, electrical components, etc., can solve the problems of large return loss and low power capacity of directional antennas, and achieve the effect of improving directivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) The working frequency of the antenna is selected as 15 GHz according to user requirements. The selected waveguide is a standard BJ140 rectangular waveguide, the length of the wide side is 15.8mm, and the length of the narrow side is 7.9mm.

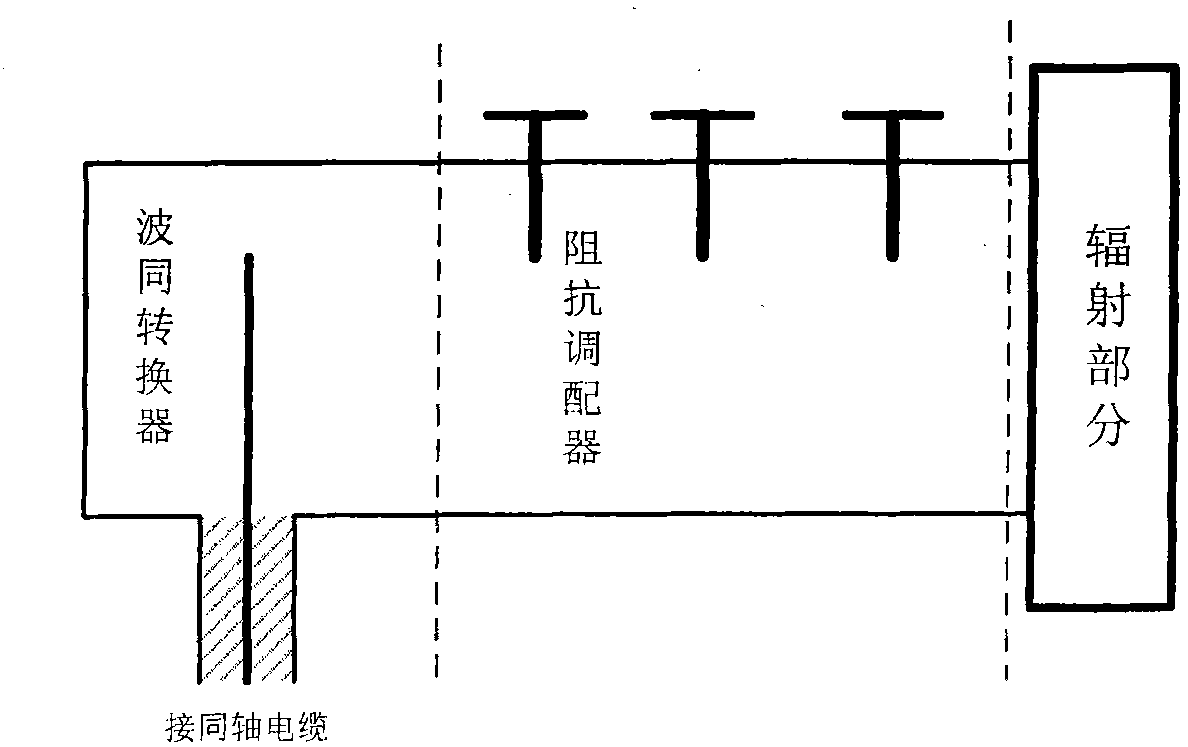

[0047] (2) The waveguide-coaxial converter is a door knob waveguide-coaxial converter. The connector is a standard N-type connector, and the surface of the streamlined inner conductor of the converter is silver-plated. The VSWR of this type of connector is wider than that of small bandwidth and supports larger power.

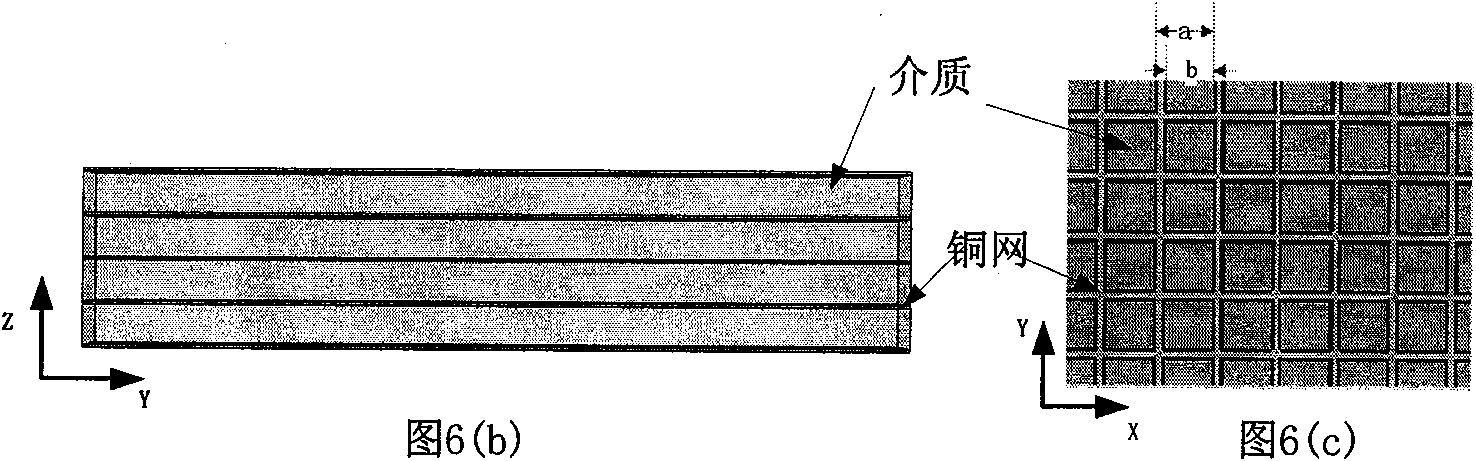

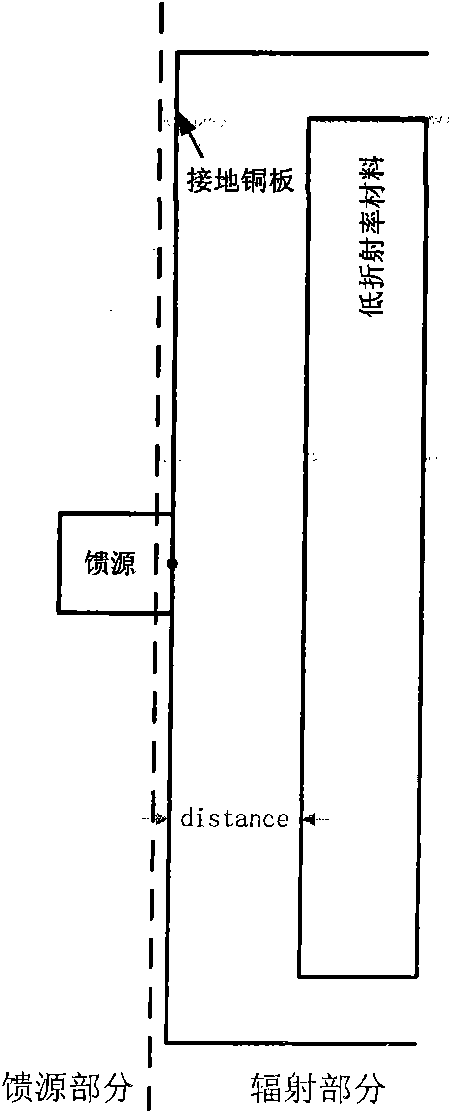

[0048] (3) The impedance adjuster uses a three-screw impedance adjuster, which has a large adjustment range, is easy to integrate into the waveguide, and has low cost. The final radiation part of the antenna is like figure 2 As shown, integrating the converter and impedance adjuster on the waveguide reduces the volume of the device.

[0049] (4) The directivity coefficient of a given antenna is D=25dB, and the apertur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com