Constant part for a paper machine

A technology for making paper and making machines, which is applied in paper machine, paper making, wet end of paper machine, etc., can solve the problem of high cost and achieve the effect of improving product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

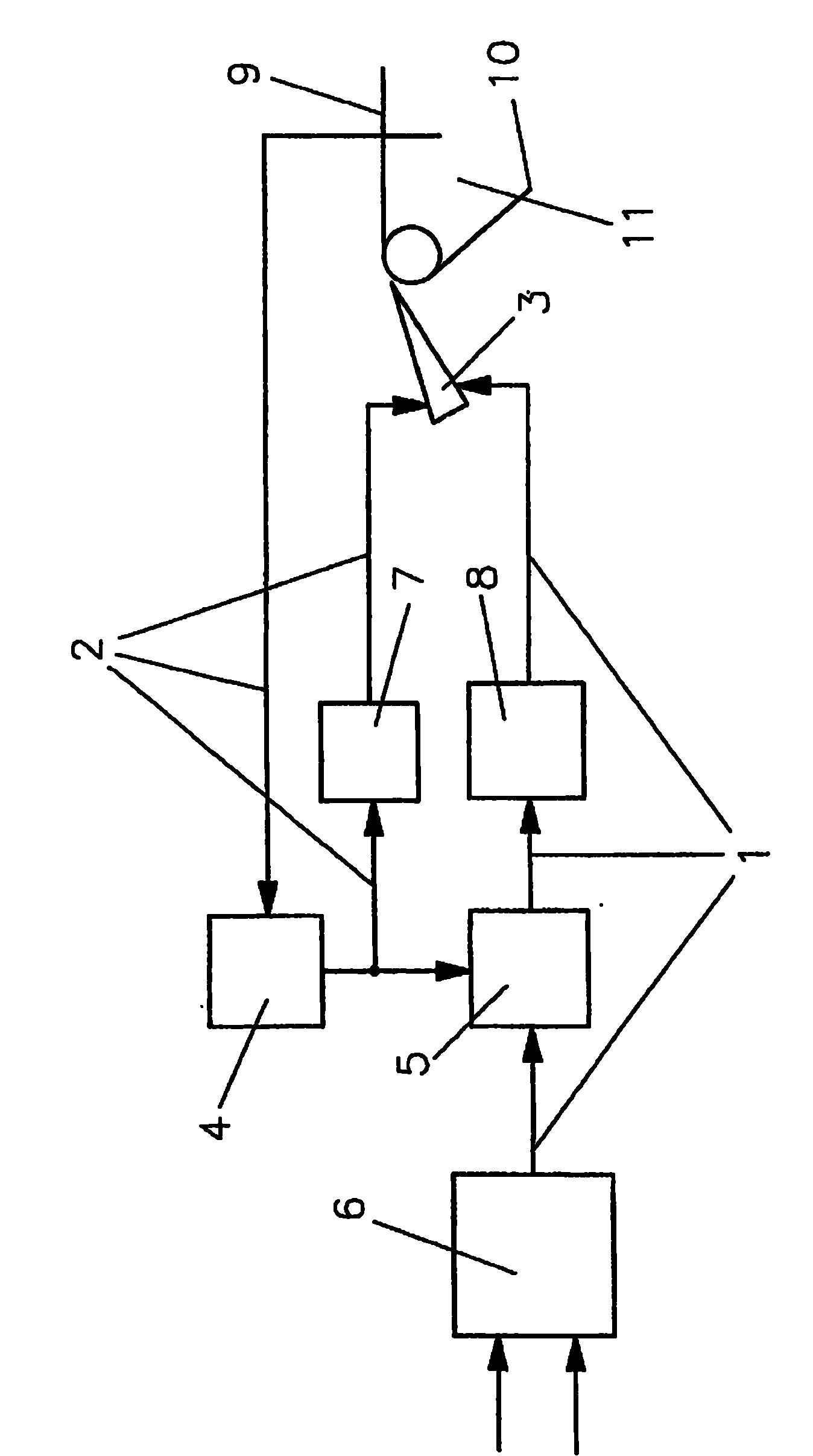

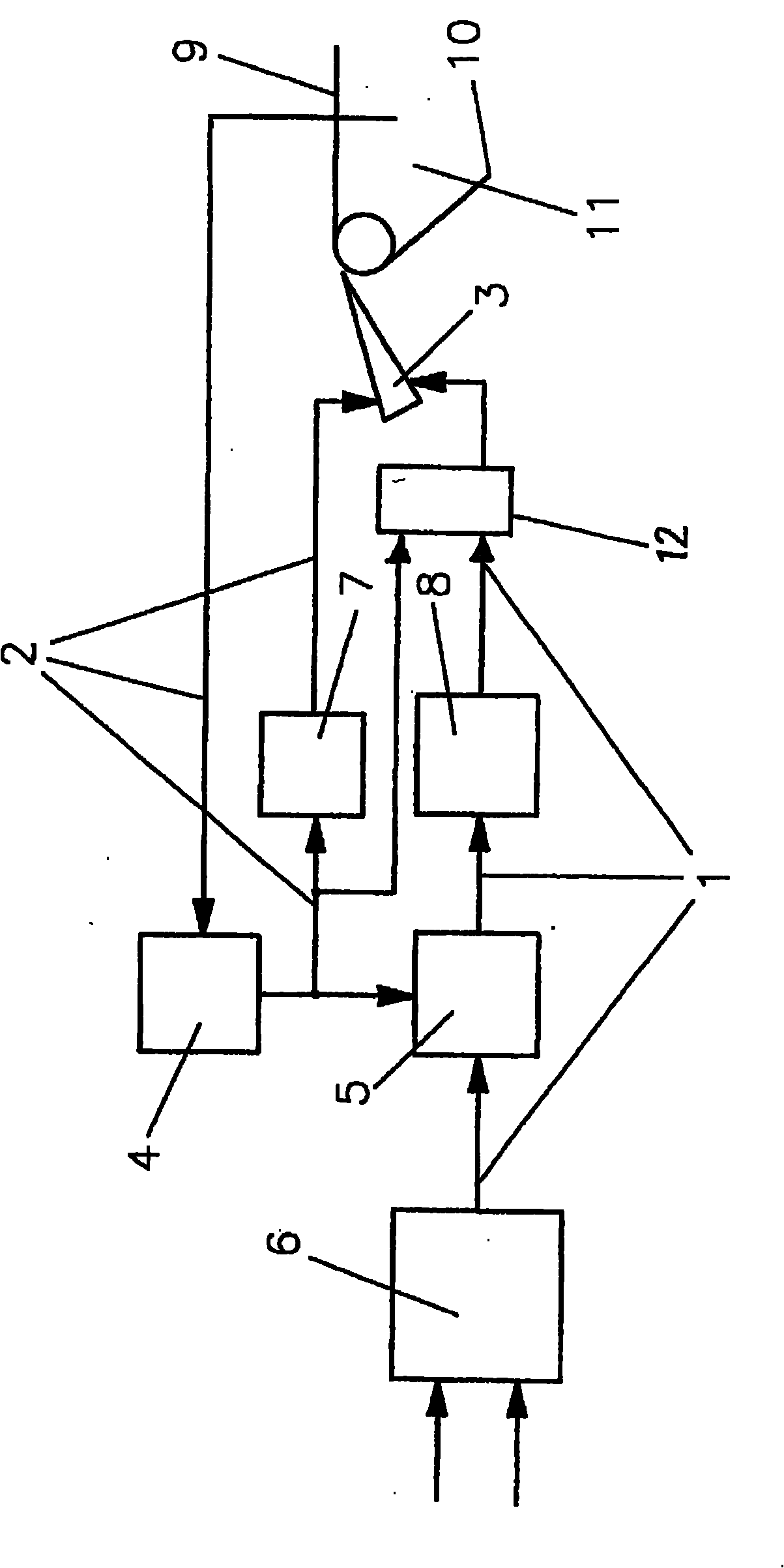

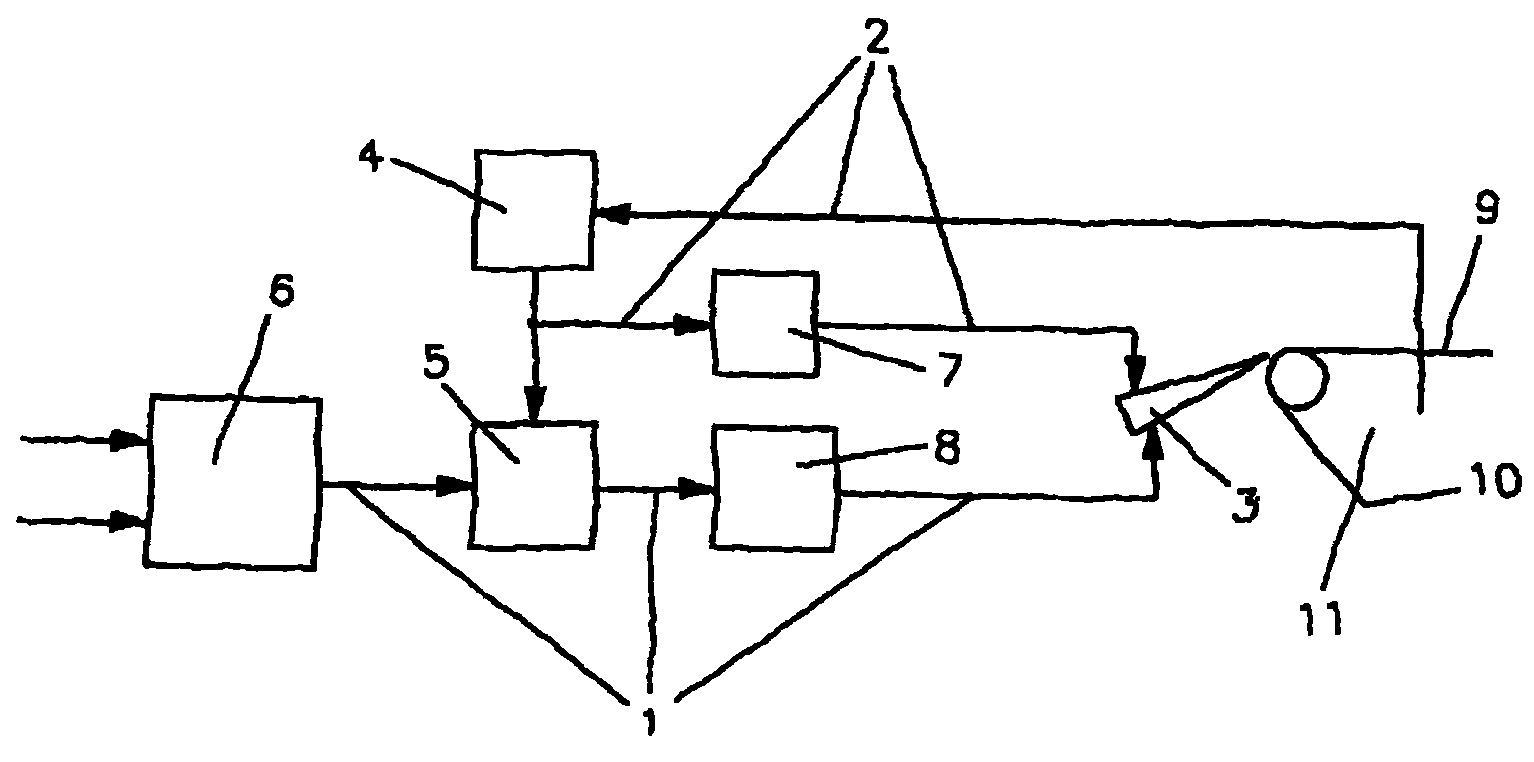

[0022] In a paper machine sizing system, the high consistency stock streams 1 in both cases are brought together and filled with fibrous material and fillers in accordance with the specifications of the paper mill, in a manner known per se, i.e. in a mixing tank 6 Mix according to the predetermined mixing ratio.

[0023] The paper machine begins with a headbox 3 and an adjoining former 11 for forming a web 9 of fibrous material. In this process, the finished stock suspension is fed onto the forming wire 10 via one or more nozzles of the headbox 3 .

[0024] In the former 11 and subsequent paper machine units, white water is collected and fed back to the sizing system. The use of white water to form the low consistency stock stream 2 not only helps to save costs compared to using fresh water, but also allows the reuse of fiber raw materials and fillers contained in the white water.

[0025] In the sizing system, the white water, that is, the low-concentration stock flow 2 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap