Fingerprint stamp pad

A printing pad and fingerprint technology, applied in the field of fingerprint printing pads, can solve problems such as complicated operation, difficult cleaning, and environmental protection, and achieve the effects of high acquisition success rate, easy cleaning, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

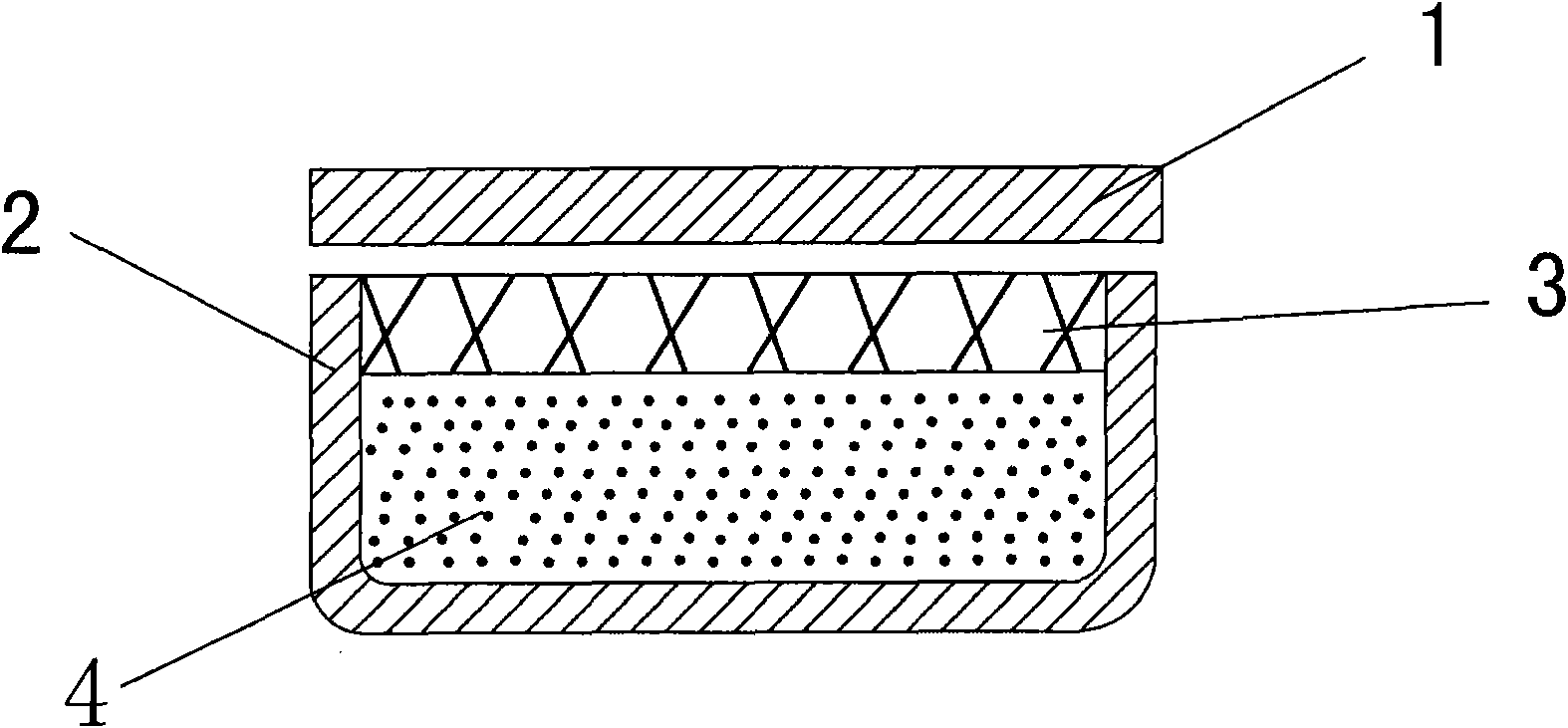

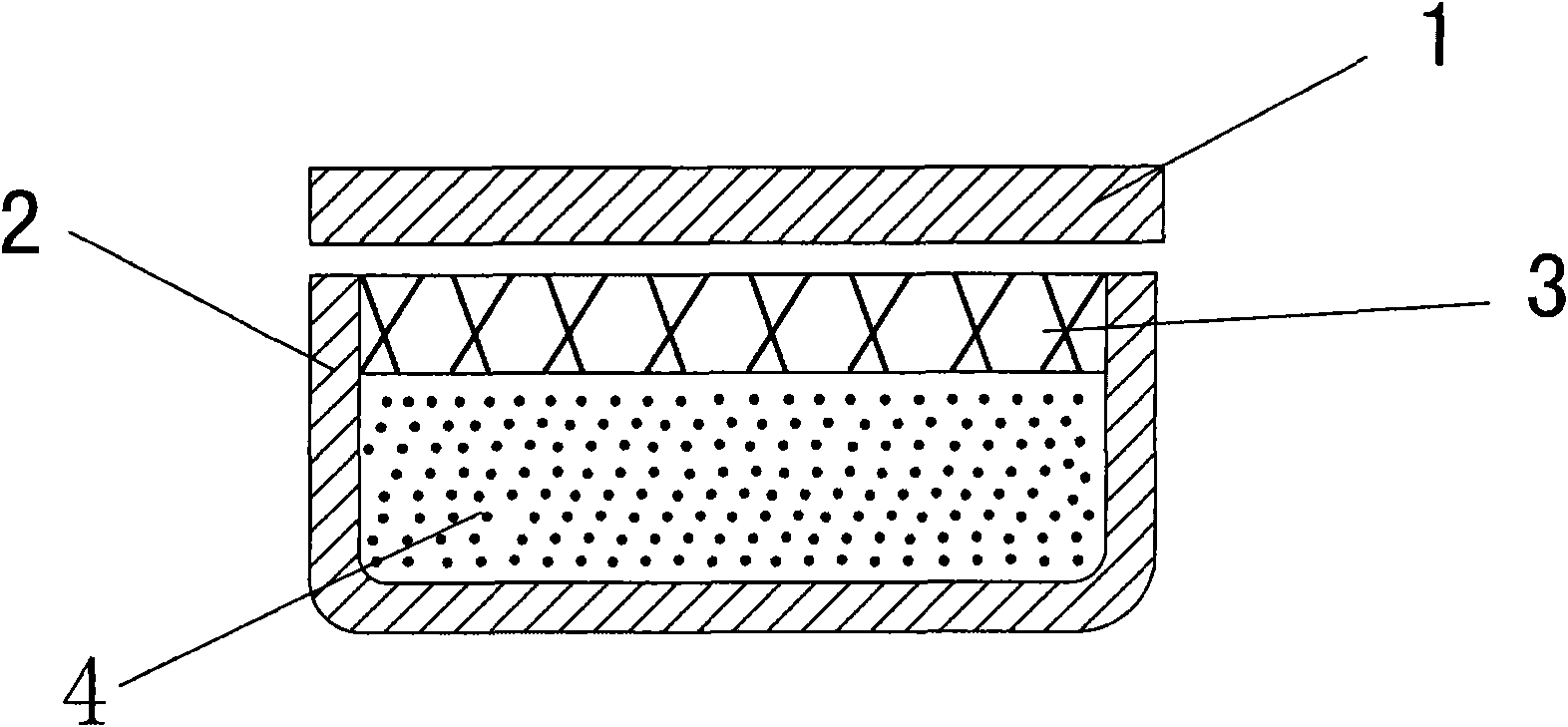

[0025] Such as figure 1 The shown fingerprint printing pad includes a platform cover 1, a pedestal 2, an oil control pad 3, an oil storage pad 4 and printing ink, and the oil storage pad 4 and the oil control pad 3 are all arranged in the pedestal 2, and the oil storage pad 4 is set At the bottom of the pedestal 2 , the oil control pad 3 is arranged on the upper part of the oil storage pad 4 , the ink is immersed in the oil storage pad 4 , and the platform cover 1 is covered on the pedestal 2 .

[0026] The oil control pad 3 is made of rubber-plastic mixed material, and the rubber-plastic mixed material contains 40-60% of PVC, 10-20% of nitrile rubber, 10-20% of light calcium carbonate, Guma Long resin 5-15%, antistatic agent 1-10%, stabilizer 1-10%, bright lubricant 1-10%. The PVC is environmentally friendly PVC, and the fineness of the rubber-plastic mixed material is 8-10um. The mesh number of described light calcium carbonate is 400-800 mesh.

[0027] The printing oil u...

Embodiment 2

[0031] The structure of the fingerprint pad in the second embodiment is exactly the same as that in the first embodiment. It also includes a table cover 1, a pedestal 2, an oil control pad 3, an oil storage pad 4 and printing ink.

[0032] The oil control pad 3 is made of a rubber-plastic composite material, which contains 57% PVC, 10% nitrile rubber, 15% light calcium carbonate, 15% coumarone resin, and anti-corrosion resin by weight percentage. Static agent 1%, stabilizer 1%, bright lubricant 1%. The PVC is environmentally friendly PVC, and the fineness of the rubber-plastic mixed material is 8-10um. The mesh number of described light calcium carbonate is 400-800 mesh.

[0033] The printing oil used in the above-mentioned fingerprint pad contains 20% of pigment, 10% of acrylic resin, 55% of moisturizing agent glycerin, 3% of emulsifying agent polyoxypropylene ether, 7% of thickening agent agar and 5% of water in percentage by weight. The fineness of the ink is 3-5um.

[...

Embodiment 3

[0037] The structure of the fingerprint pad in the third embodiment is exactly the same as that in the first embodiment. It also includes a table cover 1, a pedestal 2, an oil control pad 3, an oil storage pad 4 and printing ink.

[0038] The oil control pad 3 is made of a rubber-plastic composite material, which contains 40% PVC, 20% nitrile rubber, 15% light calcium carbonate, 10% coumarone resin, anti- Static agent 9%, stabilizer 1%, bright lubricant 5%. The PVC is environmentally friendly PVC, and the fineness of the rubber-plastic mixed material is 8-10um. The mesh number of described light calcium carbonate is 400-800 mesh.

[0039] The printing oil used in the above-mentioned fingerprint pad contains 10% of pigment, 15% of acrylic resin, 50% of moisturizing agent propylene glycol, 5% of emulsifying agent polyoxypropylene ether, 10% of thickening agent agar and 10% of water in percentage by weight. The fineness of the ink is 3-5um.

[0040] The ink in the oil storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com