Novel sea water desalinization evaporator

An evaporator, a new type of technology, is applied in seawater treatment, general water supply saving, heating water/sewage treatment, etc. It can solve the problems of easy welding leakage, high production cost, and difficult shell processing and manufacturing, so as to reduce the vibration intensity , Improve the reliability and service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

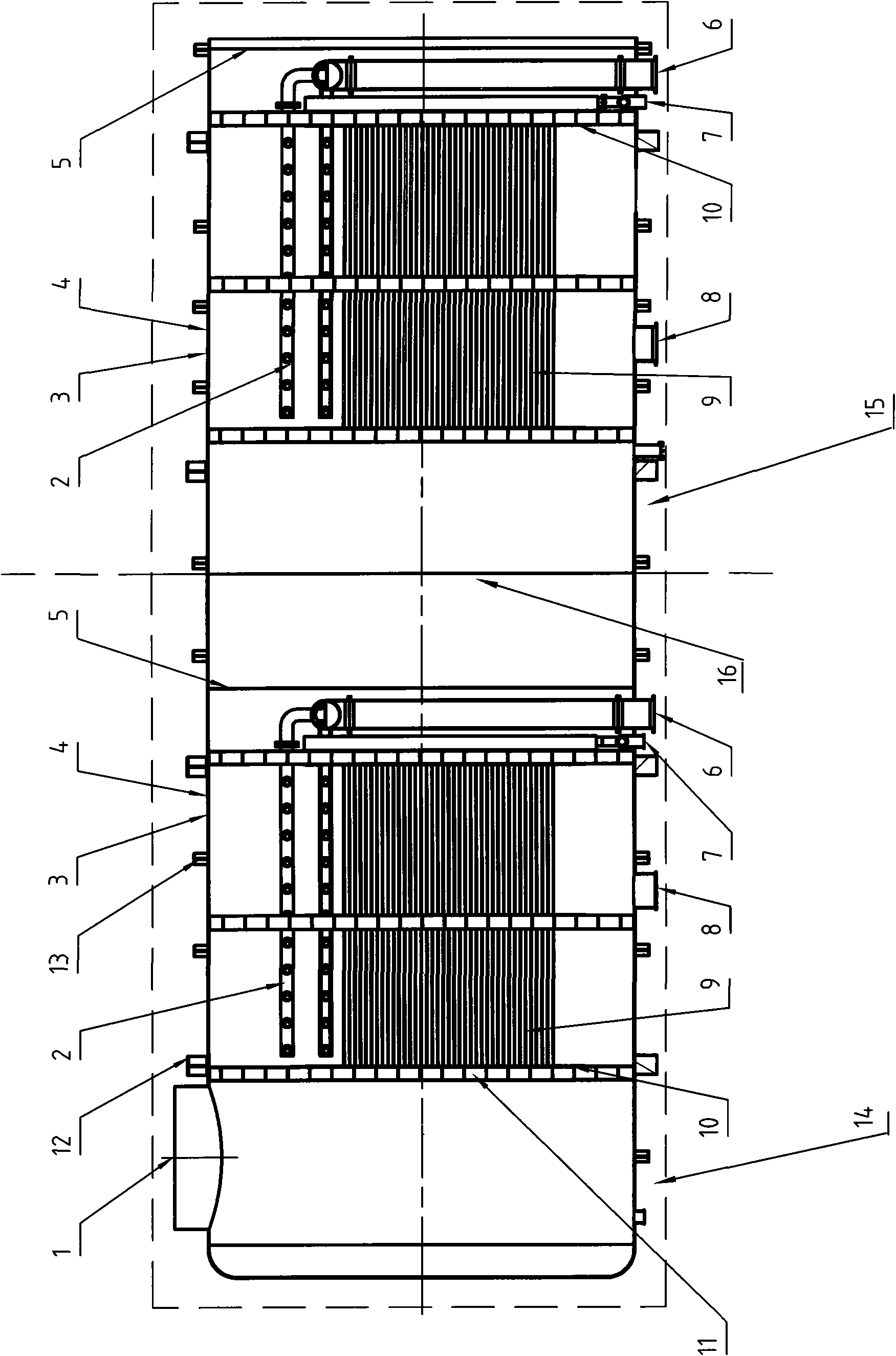

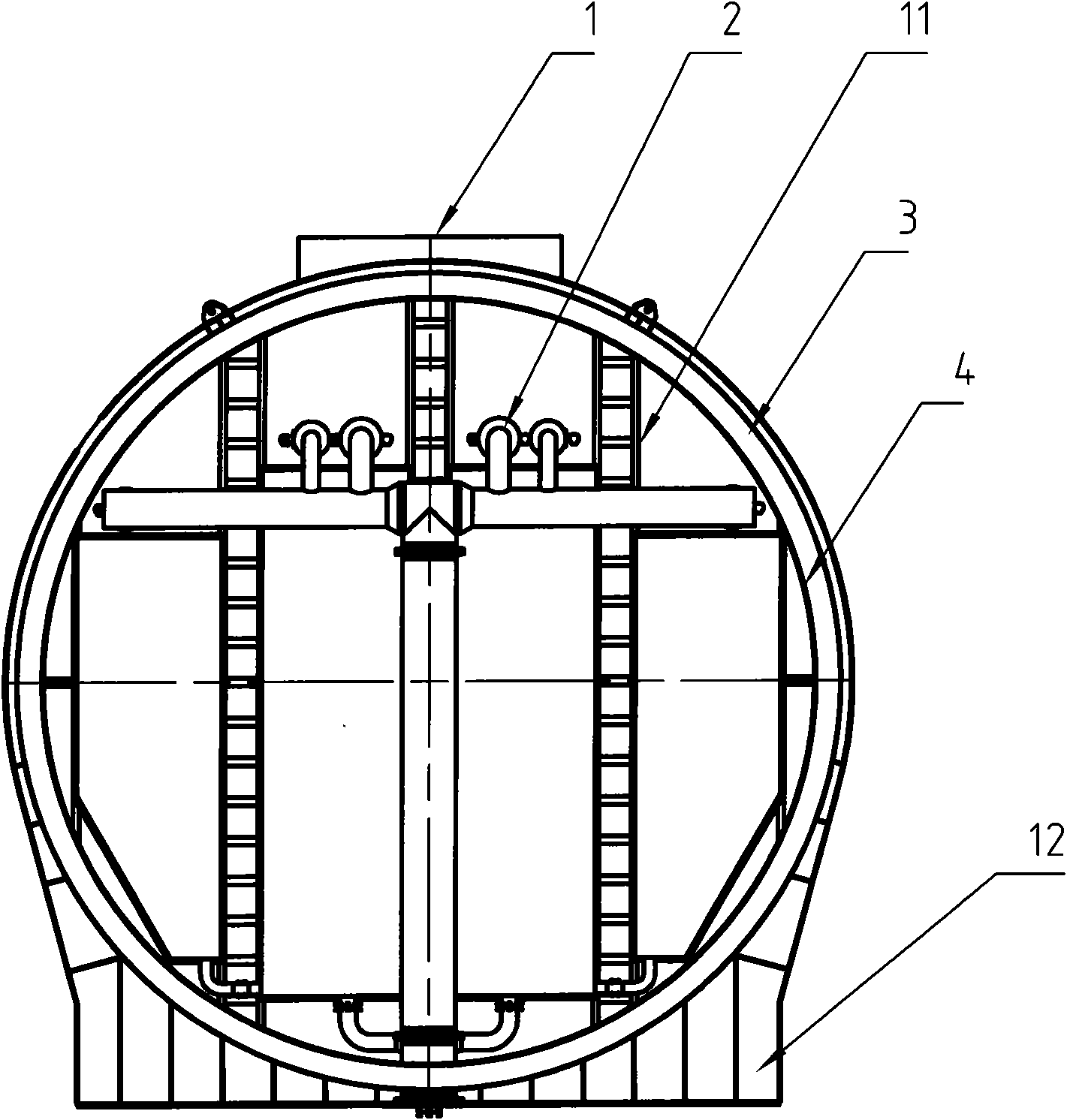

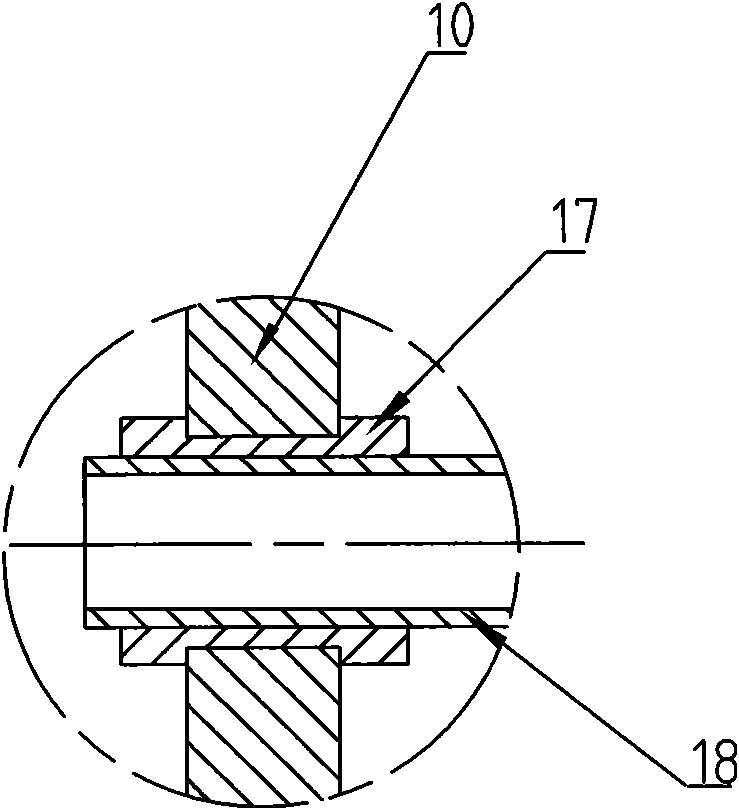

[0017] The embodiment shown in the drawings is a seawater desalination evaporator formed by connecting two effect evaporators. The evaporator shell 3 is welded by the shells of the first-effect evaporator and the second-effect evaporator. The shell is made of ordinary carbon steel, and its inner wall is coated with food-grade water-resistant epoxy resin coating 4 for heat exchange. The tube bundle 9 and the tube sheet 10 are elastically sealed and fixed on the internal support 11 with food-grade silicone rubber sealing ring 17. The evaporator is equipped with sufficient external reinforcement support 13 in order to ensure the rigidity, and the external support 12 can be connected with seawater. The foundation base of the desalination system is connected and fixed. The initial steam of the evaporator enters the heat exchange tube bundle 9 from the steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com