Extraction method of red cabbage pigment

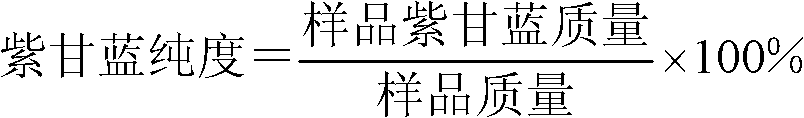

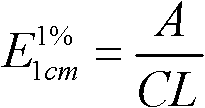

An extraction method and technology for purple cabbage, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of low pigment purity, and achieve the effects of high color value, improved biological activity, and improved color value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: 1) After cleaning the silt, removing the roots, removing the pests and defective leaves, the mature purple cabbage is chopped, and the chopped purple cabbage is mixed with water in a mass ratio of 1:5 and placed in a beater Beat into a slurry, the slurry is coarsely filtered with a vibrating sieve and the filtrate is collected, and the pH value of the filtrate is adjusted to 3.0 with 6mol / L HCl;

[0026] 2) Add compound pectinase to the filtrate at a ratio of 100g purple cabbage: 0.002ml at 50°C, enzymolyze at 45°C for 60 minutes and clarify, centrifuge the filtrate after enzymolysis and clarification at 4000 rpm for 20 minutes, centrifuge The resulting supernatant is the pigment clear liquid;

[0027] 3) Put the pigment clear liquid on the LSA-21 macroporous adsorption resin column for pigment adsorption. The flow rate of the pigment clear liquid on the column is 1.0 times the column volume / hour, and the temperature on the column is 40°C. Desorb the pigment...

Embodiment 2

[0028] Example 2: 1) After washing the silt, removing the roots, removing the pests and defective leaves, the mature purple cabbage is chopped, and the chopped purple cabbage is mixed with water in a mass ratio of 1:5 and placed in a beater Beat into a slurry, the slurry is coarsely filtered with a vibrating sieve and the filtrate is collected, and the pH value of the filtrate is adjusted to 3.5 by using 6mol / L of HCl;

[0029] 2) Add compound pectinase to the filtrate at a ratio of 100g purple cabbage: 0.002ml at 45°C, enzymolyze at 50°C for 60 minutes and clarify, centrifuge the filtrate after enzymolysis and clarification at 4000 rpm for 20 minutes, and centrifuge The resulting supernatant is the pigment clear liquid;

[0030] 3) Put the pigment clear liquid on the LSA-21 macroporous adsorption resin column for pigment adsorption. The flow rate of the pigment clear liquid on the column is 1.0 times the column volume / hour, and the temperature on the column is 20°C. Desorb t...

Embodiment 3

[0031] Embodiment 3: 1) After cleaning the silt, removing the roots, removing the pests and defective leaves, the mature purple cabbage is chopped, and the chopped purple cabbage is mixed with water in a mass ratio of 1:5 and placed in a beater Beat into a slurry, the slurry is coarsely filtered with a vibrating sieve and the filtrate is collected, and the pH value of the filtrate is adjusted to 4.0 by using 6mol / L of HCl;

[0032] 2) Add compound pectinase to the filtrate at a ratio of 100g purple cabbage: 0.003ml at 45°C, enzymolyze at 48°C for 60 minutes and clarify, centrifuge the filtrate after enzymolysis and clarification at 4000 rpm for 20 minutes, and centrifuge The resulting supernatant is the pigment clear liquid;

[0033] 3) Put the pigment clear liquid on the LSA-21 macroporous adsorption resin column for pigment adsorption. The flow rate of the pigment clear liquid on the column is 1.0 times the column volume / hour, and the temperature on the column is 50°C. Deso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com