Cell opto-acoustic microscopic imaging method and device thereof

A technology of photoacoustic microscopy and imaging method, applied in measurement devices, generation of ultrasonic/sonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, etc. lower problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

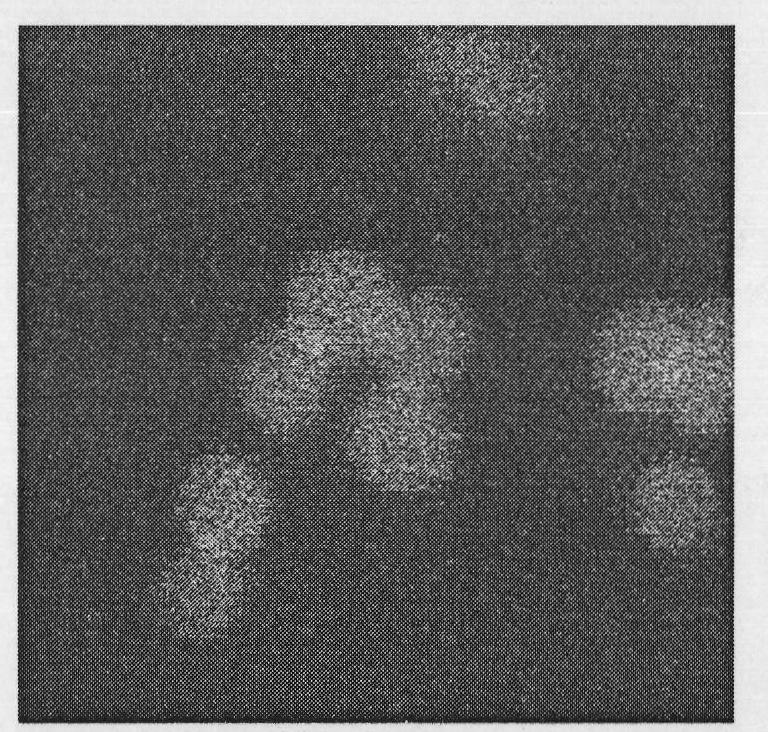

Image

Examples

Embodiment Construction

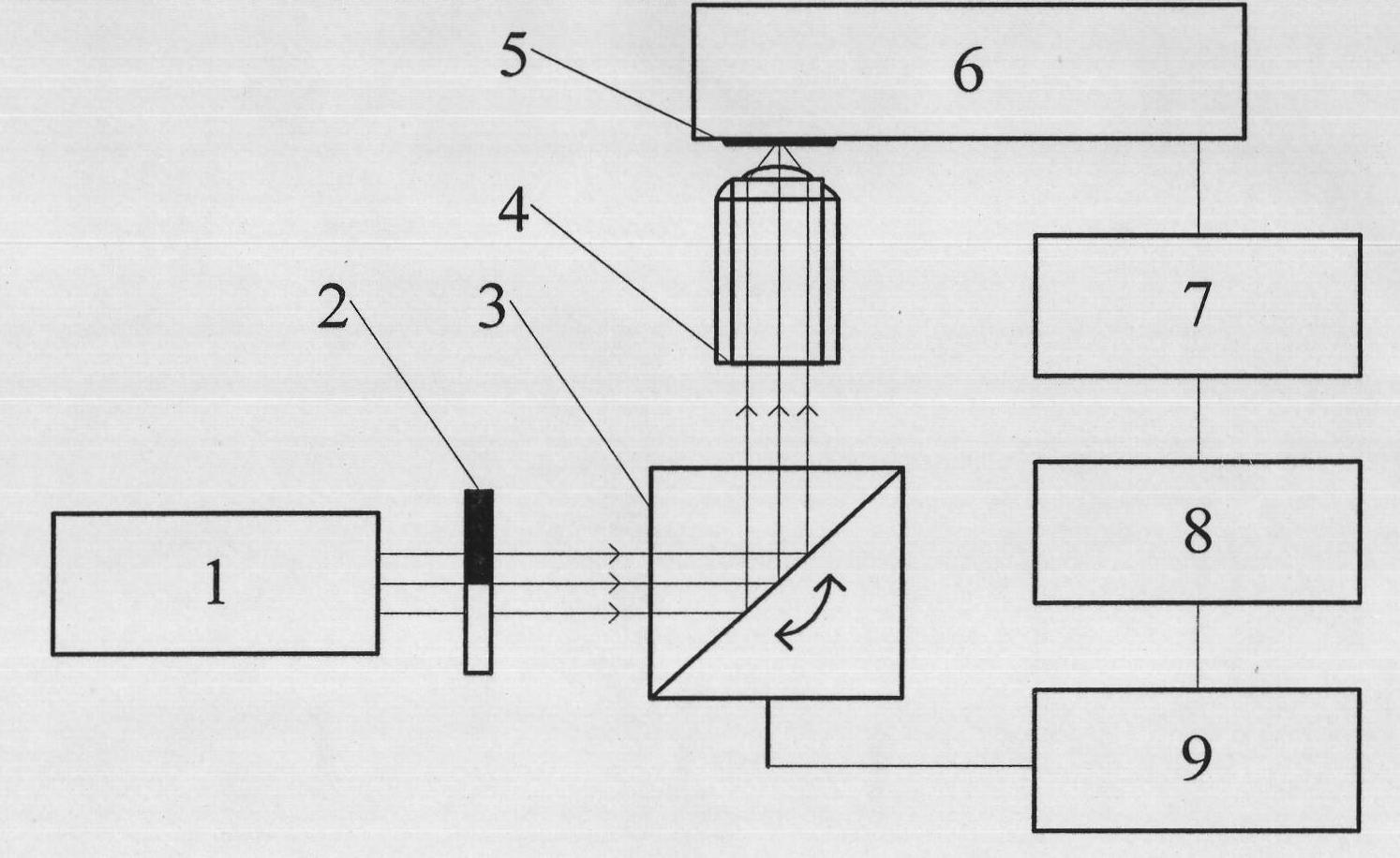

[0021] Such as figure 1 As shown, the device of the present invention includes three parts: a laser scanning imaging mechanism, a photoacoustic sensor and a signal processor. Wherein, the laser scanning imaging mechanism is composed of a laser 1, a scanning vibrating mirror 3, and a microscopic objective lens 4; during operation, the scanning vibrating mirror 3, the microscopic objective lens 4 and the photoacoustic sensor 6 can be installed on the microscope bracket;

[0022] The signal processor is composed of a chopper 2, a lock-in amplifier 7, an acquisition card 8 and a computer 9, which are electrically connected in turn.

[0023] The working process of the present invention is as follows: the laser light emitted by the laser device 1 is modulated by the chopper 2, then enters the laser scanning vibrating mirror 3 for two-dimensional scanning, and then is focused on the surface of the sample 5 by the microscopic objective lens 4. The photoacoustic signal is detected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com