Skidproof ventilated cushion

A breathable seat, anti-skid technology, applied in mattresses, spring mattresses, thigh cushions, etc., can solve problems such as reduced comfort, difficult to clean dirt, shortened seat service life, etc., to improve convenience and durability, eliminate Driving safety hazards and the effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

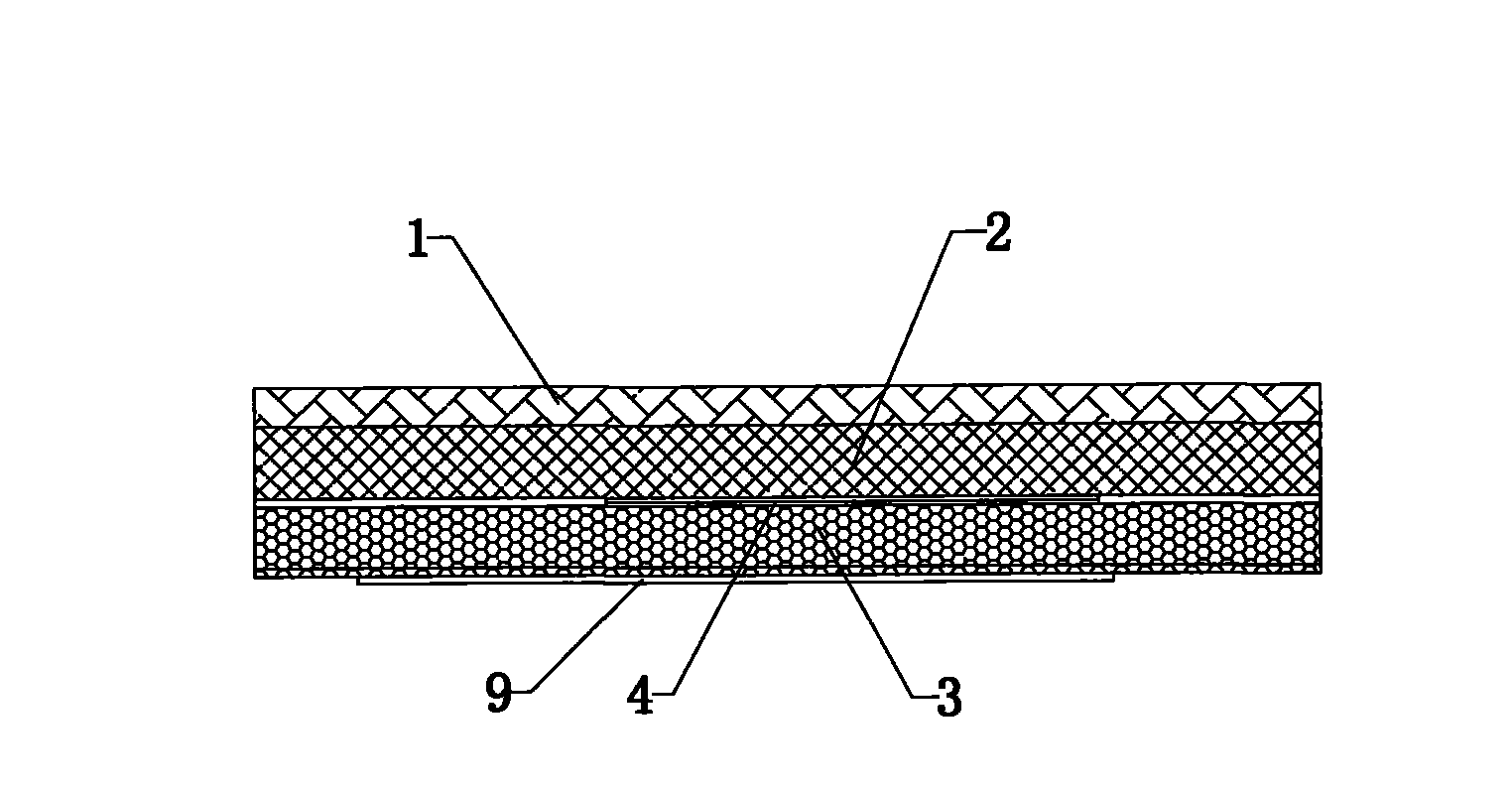

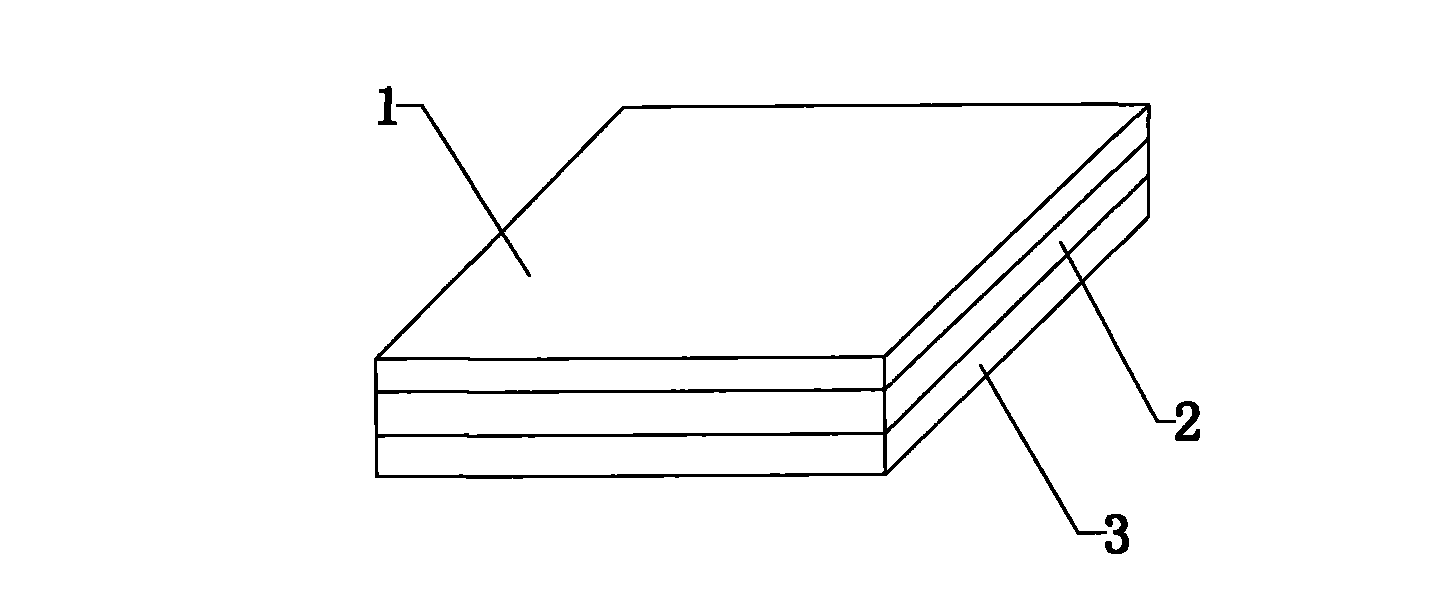

[0025] Such as Figure 1-3 As shown, the present invention provides a non-slip breathable seat cushion, comprising cortex, fiber or chemical fiber material surface layer 1, soft material middle layer 2, silica gel or latex non-slip bottom layer 3 and magic buckle 4, the bottom of soft material middle layer 2 Silicone or latex non-slip bottom layer 3 is provided, the top of the soft material middle layer 2 is provided with a cortex, fiber or chemical fiber material surface layer 1, a part of the magic buckle 4 is set on the soft material middle layer 2, and the other part of the magic buckle 4 is set On the silica gel or latex non-slip bottom layer 3, the soft material middle layer 2 is connected with the silica gel or latex non-slip bottom layer 3 through the magic buckle 4.

[0026] The silica gel or latex non-slip bottom 3 is provided with at least one sticky strip 9 .

[0027] In the middle layer 2 of soft material, the soft material is memory foam, and the magic buckle 4 ...

Embodiment 2

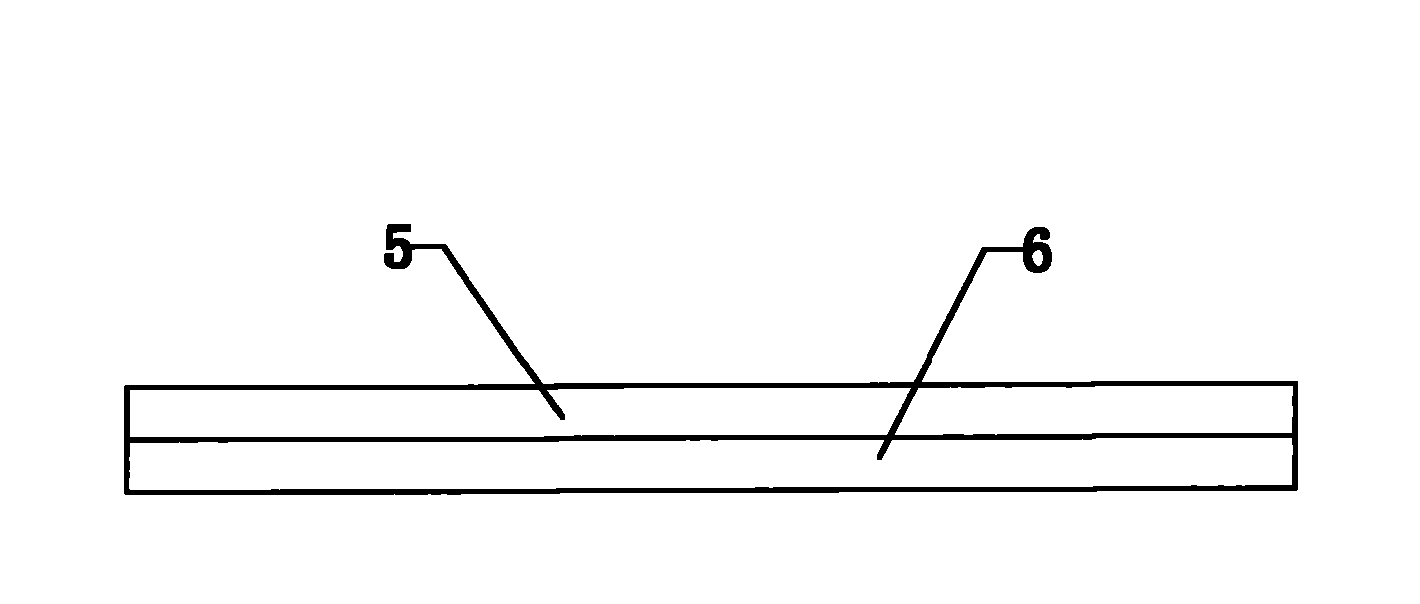

[0029] Such as Figure 4 As mentioned above, compared with Embodiment 1, the difference of this embodiment is that in the middle layer of soft material 2, the soft material is sponge, and the magic buckle 4 is a sub-button. In the sub-button, the female buckle 6 is set On the middle layer 2 of soft material, sub-buckles 5 are arranged on the bottom layer 3 of silicone or latex non-slip.

Embodiment 3

[0031] Such as Figure 5 As mentioned above, compared with Embodiment 1, the difference of this embodiment is that in the soft material middle layer 2, the soft material is latex, and the Velcro 4 is a male and female button. Among the male and female buttons, the female button 7 is arranged on the On the middle layer 2 of the soft material, the male buckle 8 is arranged on the bottom layer 3 of the silica gel or latex non-slip.

[0032] The present invention is a product targeted at various application fields and places, especially in the field of car seats, which is specially developed and designed according to various factors such as car models, seat materials, use occasions, time and climate. Realize exclusive use for special cars and special models; according to different models, according to the seat characteristics of various models, targeted design, material selection, cutting, and production. For leather seats, different materials are selected under different climatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com