Laser hole-cutting device for wall-flow type honeycomb ceramic filter core and using method thereof

A technology of honeycomb ceramics and laser cutting, which is applied in the direction of laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of slow operation speed, drop, leakage, etc., and achieve the effect of positioning and high-precision positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

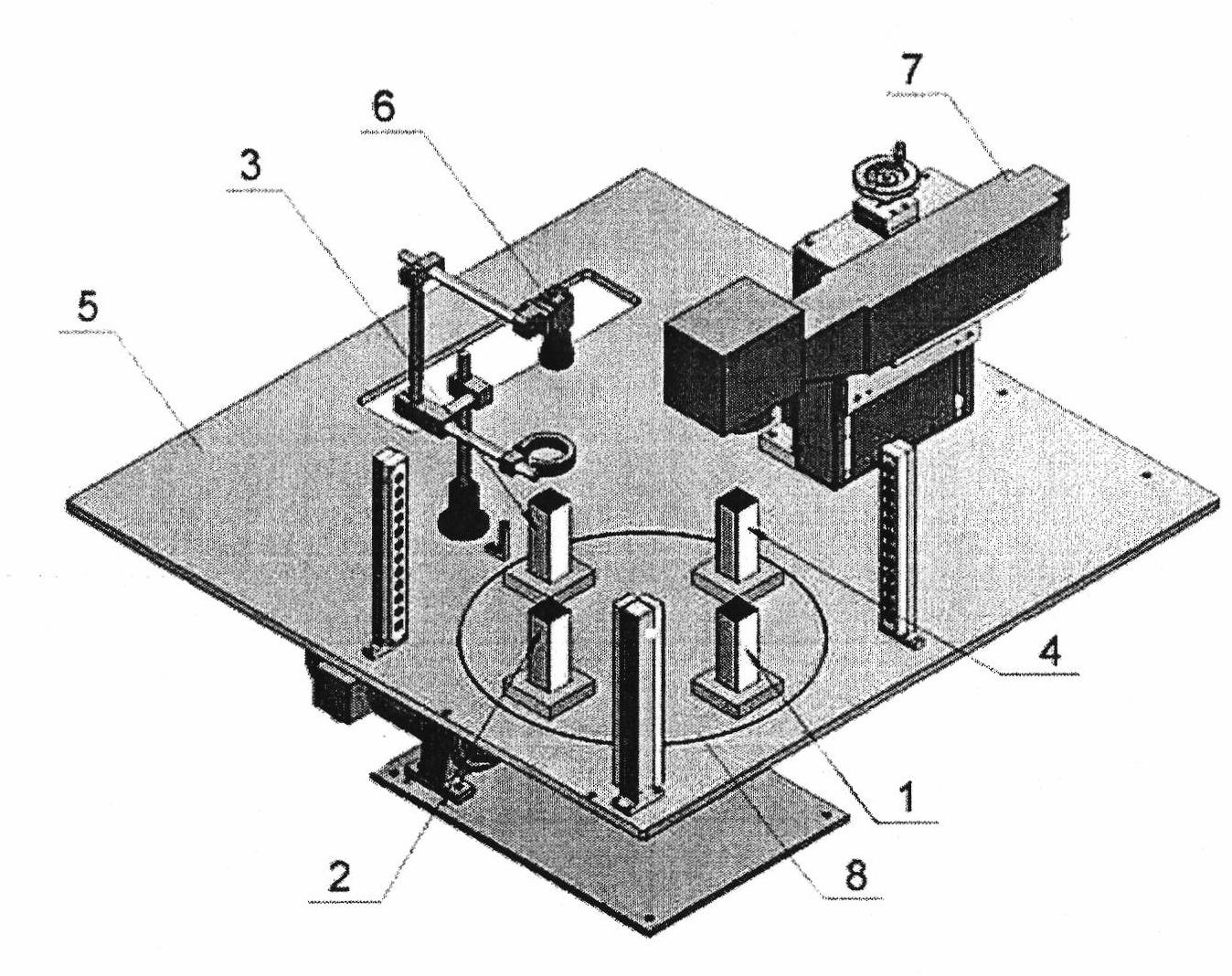

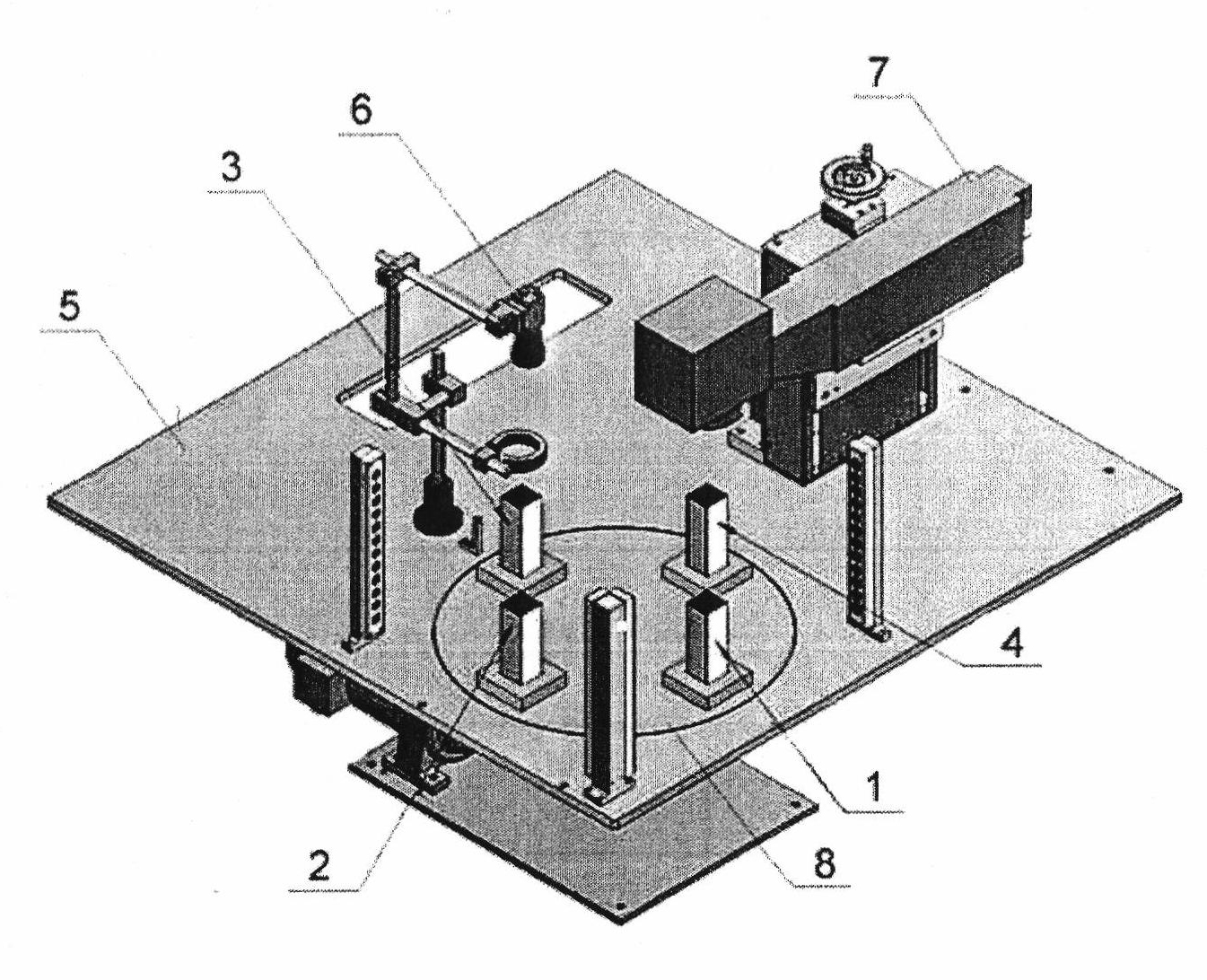

[0031] As mentioned above, the hole cutting device provided by the present invention includes a laser system, an image recognition system, a turntable, an electric control system and a software system.

[0032] Wherein, the laser system is composed of a laser generator 7, a prism and a bracket (not shown in the figure). The laser beam emitted by the laser can change its direction by turning the prism.

[0033] 2. Image recognition system

[0034] Including CCD sensor, image processing circuit and other components. The position of the workpiece can be accurately captured and fed back to the computer, and the position of the marking graphic can be corrected through the software system.

[0035] 3. Turntable: It consists of feeding station 1, film installation station 2, camera station 3 and hole cutting station 4, each station is 90° apart, and the above three parts are placed on the workbench.

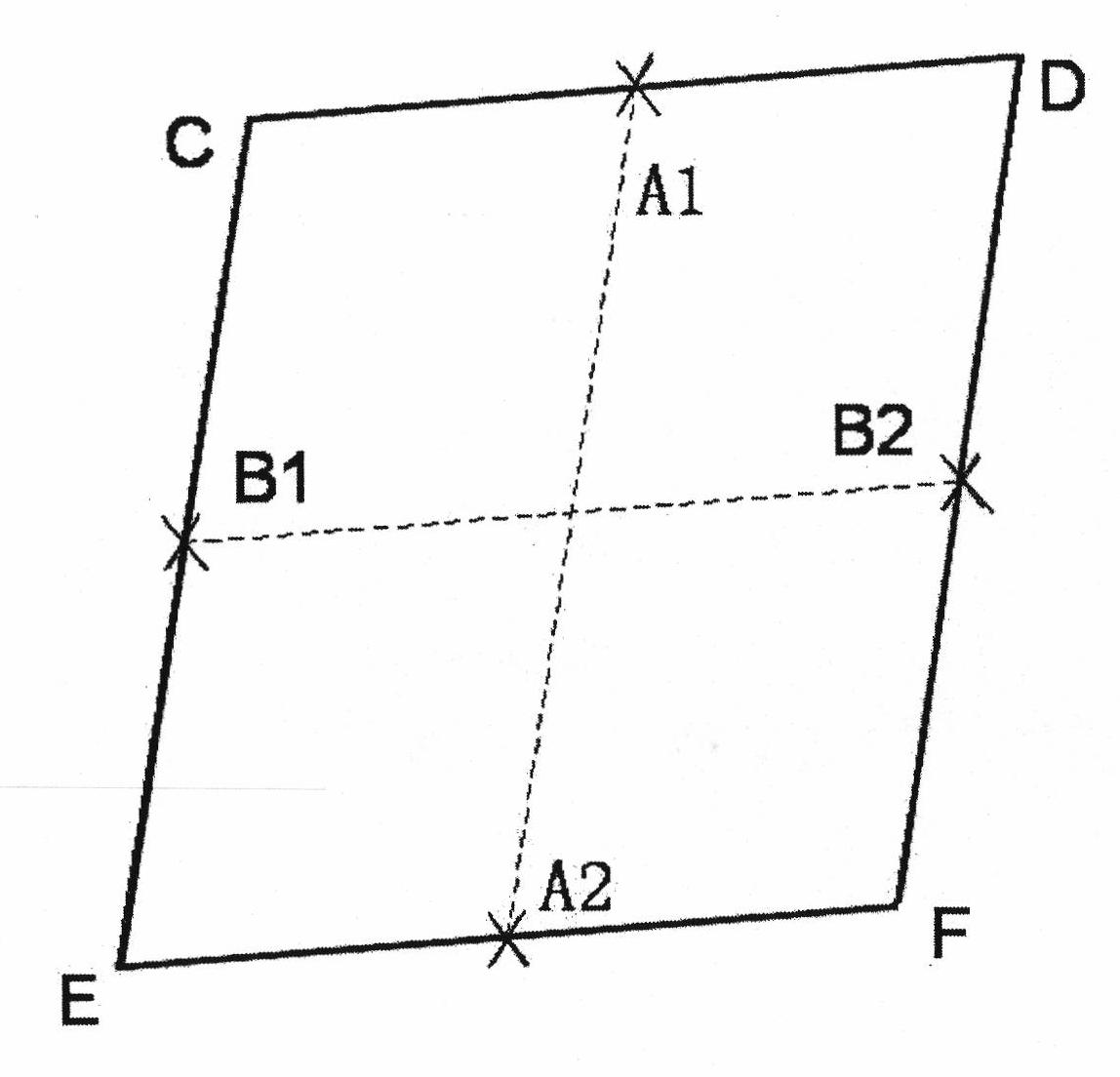

[0036] At camera station 3, the wall-flow honeycomb ceramic filter element to be...

Embodiment 2

[0038] 1) Fix the honeycomb ceramic filter element with a size of 35.62×35.78×255.50mm in the groove of the fixture bottom plate of the loading station.

[0039] 2) Press the "Start" button to make the turntable rotate to the film installation station at 1.5 seconds per station, and install the film;

[0040] 3) The turntable rotates to the CCD camera station, and the CCD starts to capture the hole position data of the honeycomb ceramic filter element;

[0041] 4) After the CCD is captured, the honeycomb ceramic filter element moves to the hole cutting station with the turntable, and the laser starts to cut holes and mark the end face of the filter element at intervals. In this way, the adjacent holes around each through hole are all blocked, and the adjacent holes around each blocked hole are all opened, which facilitates the smooth progress of the plugging process in the preparation process of the honeycomb ceramic filter element;

[0042] 5) After the marking is completed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com