Rotary tubular dynamic membrane bioreactor adopting nonwovens and sewage treatment method thereof

A sewage treatment method and bioreactor technology, applied in the field of environmental engineering, can solve the problems of reducing investment and operating costs, achieve low cost, strong anti-pollution performance, and ensure the suspension of activated sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

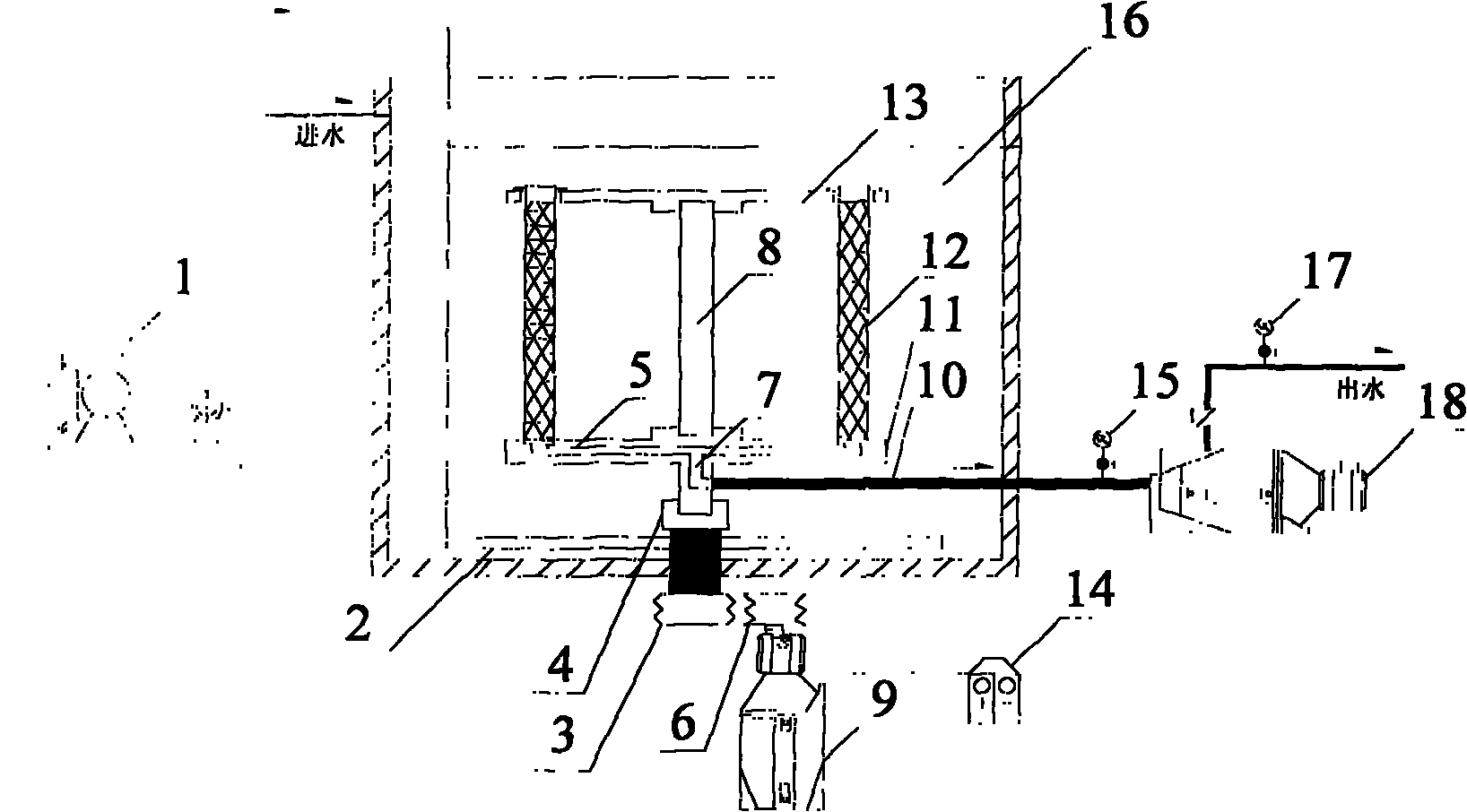

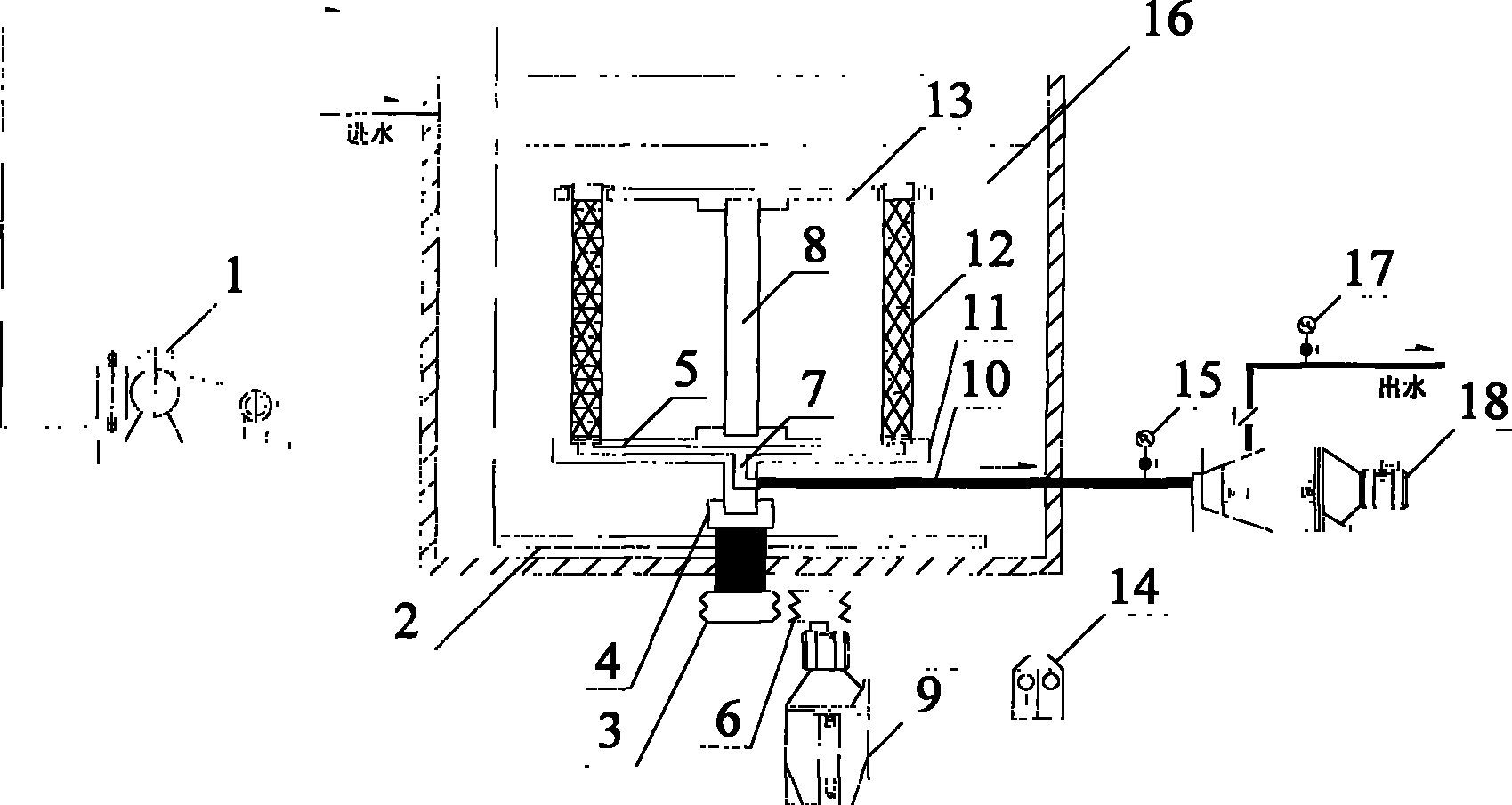

[0022] The amount of domestic sewage treated is 40m 3 / d, the COD concentration is 600mg / L. The hollow tube is wrapped with non-woven fabric to form a tubular filter module 12, and the flux of a single tubular membrane module is maintained at 80L / h·m 2 . The filter area of the tubular filter module is 1.3m 2 , it is calculated that 16 filter components are required, and its specific size is an effective length of 2m and a radius of 0.1m. The hydraulic retention time in the bioreactor 16 is 8 hours, and the effective volume is 13.3m 3 , its specific dimensions are: diameter width 2.5m, effective water depth 2.8m, super height 0.5m, total height 3.3m.

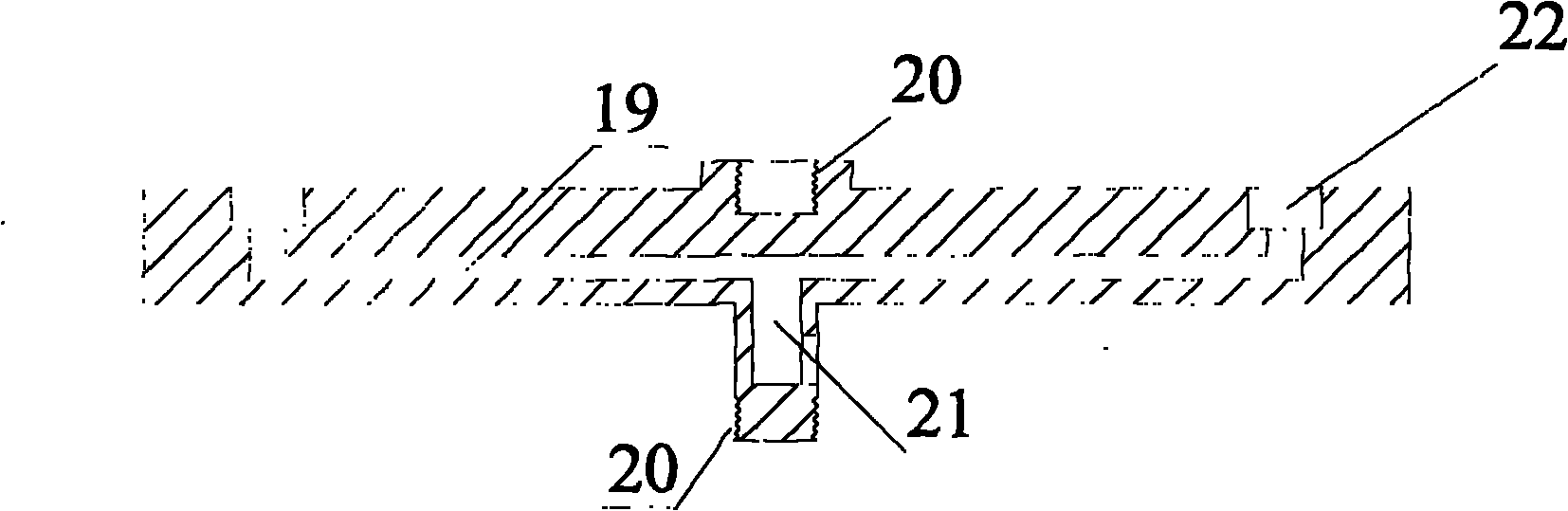

[0023] The radius of the upper and lower discs is equal, set to 1.0m, 16 slots and jacks are arranged in a ring at a position 0.8m away from the center of the disc, each slot and jack has a radius of 0.1m, and the distance between the centers of adjacent slots and the shortest distance 0.31m and 0.11m respectively, 16 tubu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com