Heat treatment method for cold-rolled steel strip

A heat treatment method and cold-rolled steel strip technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of imperfect surface quality, less material utilization, and large gaps in the cover, so as to reduce heat and reduce energy consumption , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

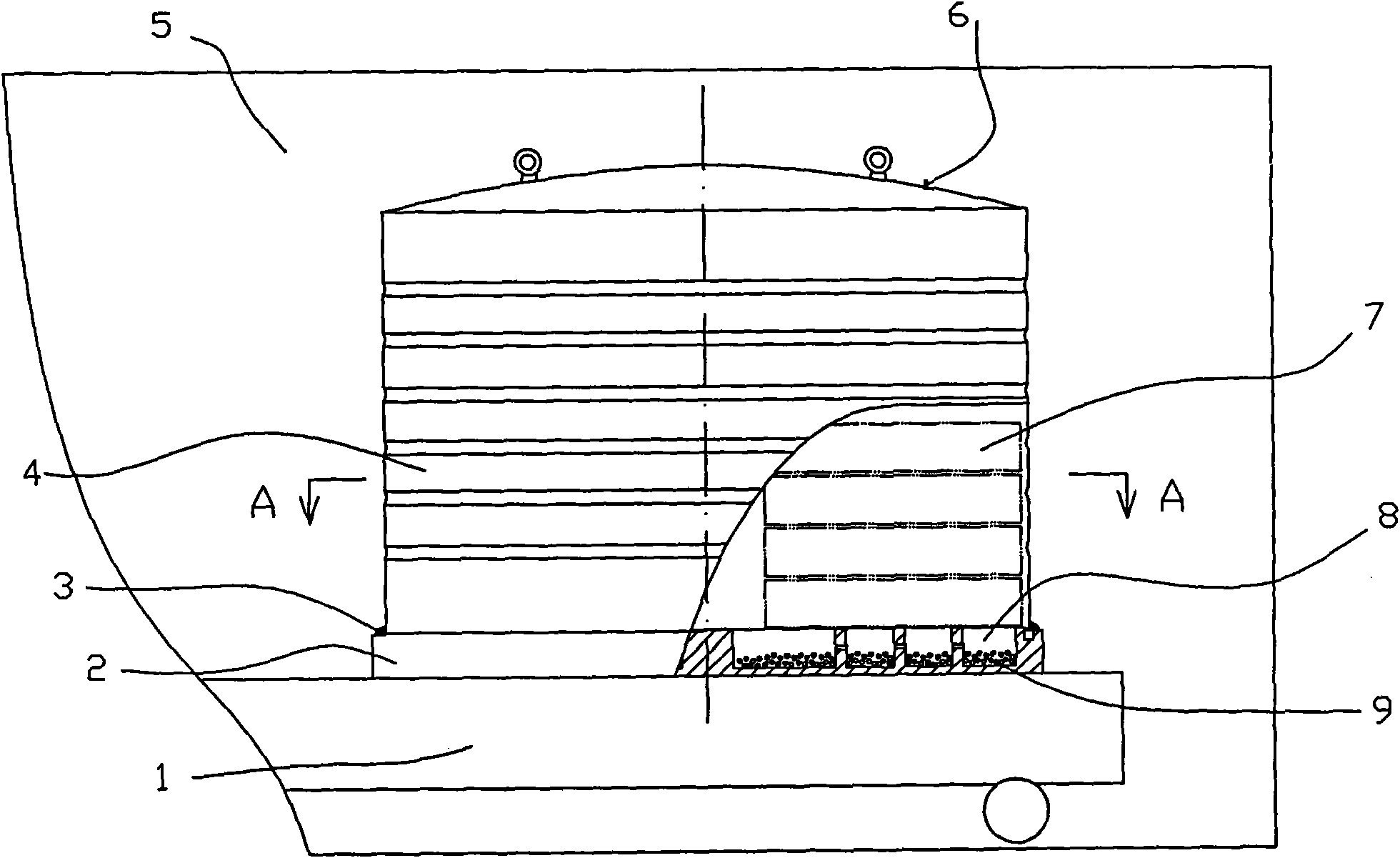

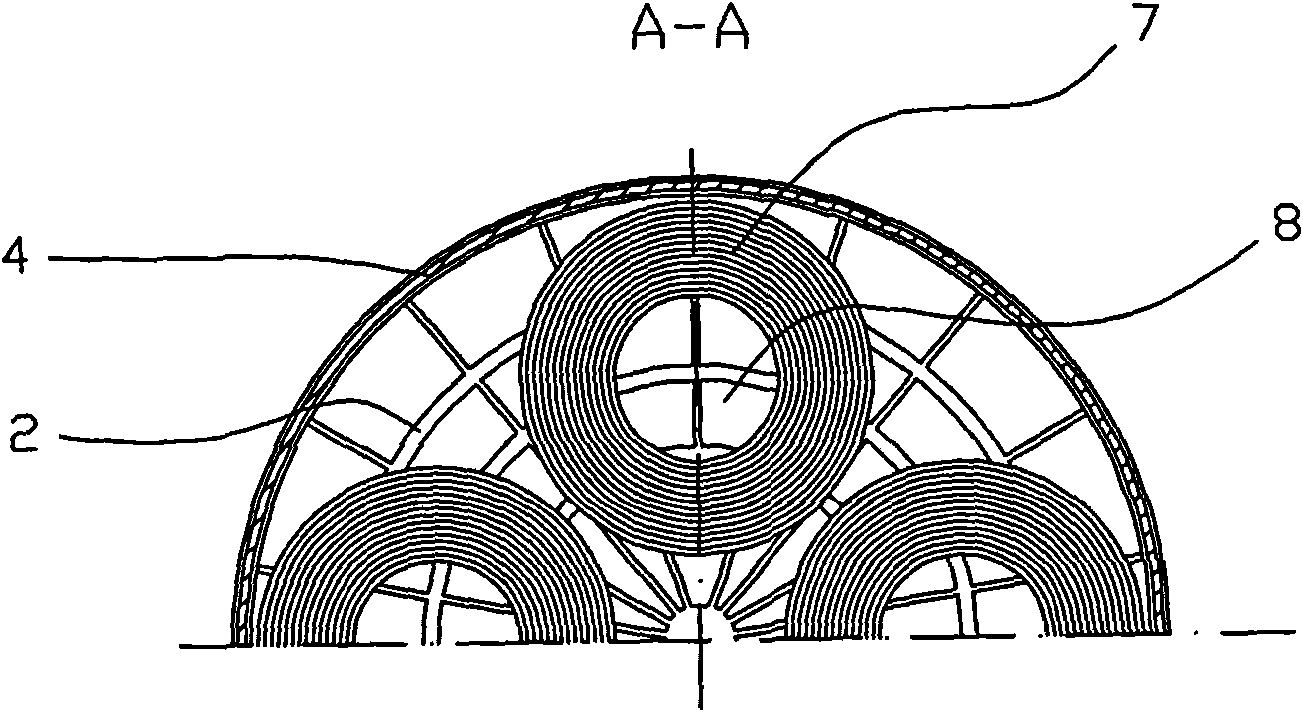

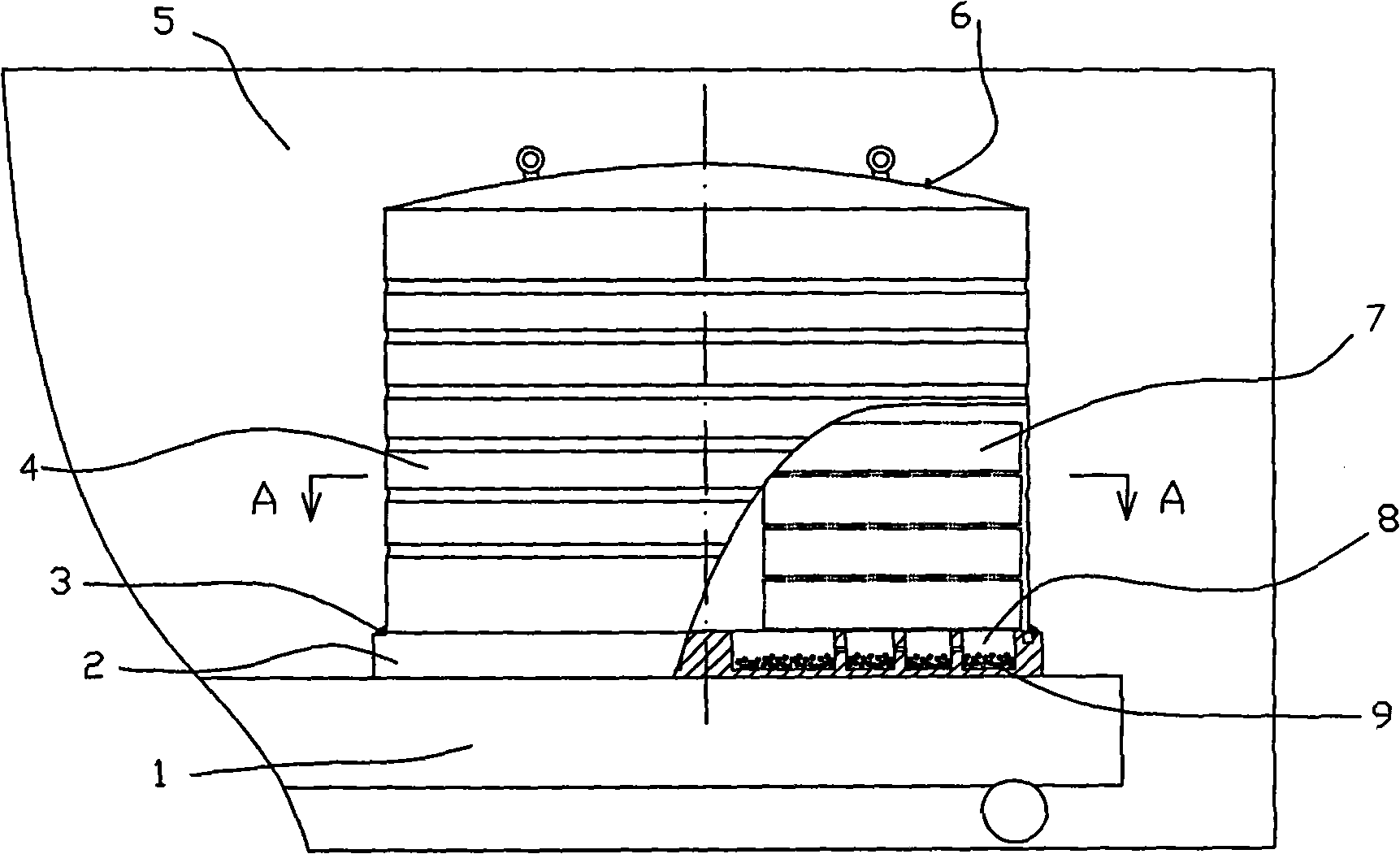

[0012] Such as figure 1 , 2 As shown, the method of the present invention uses a furnace 5, a trolley 1, and a shield as heat treatment equipment. The shield includes a bell-shaped stainless steel cover 4 and a disc-shaped base 2. The shield connects the The cold-rolled steel strip 7 is sealed in it (the sand seal groove 3 is used to realize the sealing between the cover body 4 and the base 2), and the whole is placed on the trolley 1, and then enters the furnace 5, the bottom surface of the base 2 in the protective cover There are labyrinth grooves 8 communicating with each other, and magnesium, aluminum or zinc metal particles 9 are placed in the grooves 8.

[0013] After entering the kiln 5 with the whole protective cover containing the cold-rolled strip steel 7, it is heated to 900-910°C and kept for 20-24 hours; then, the fire is stopped, and it is allowed to stand in the kiln 5 for 18-20 hours; then, Exit the kiln 5, place it still in an environment of 10-30°C, and cool to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com